Axle box rubber cushion, bogie and railway vehicle

A technology for axlebox rubber pads and railway vehicles, which is applied in the fields of axlebox rubber pads, bogies and railway vehicles, and can solve the problem of slow attenuation of elastic potential energy, reduced running stability and safety of railway vehicles, and the problem that the upper lining plate 1′ and the lower The problem of slow attenuation of vibration and kinetic energy of the liner 2' can avoid serpentine motion and improve operation stability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

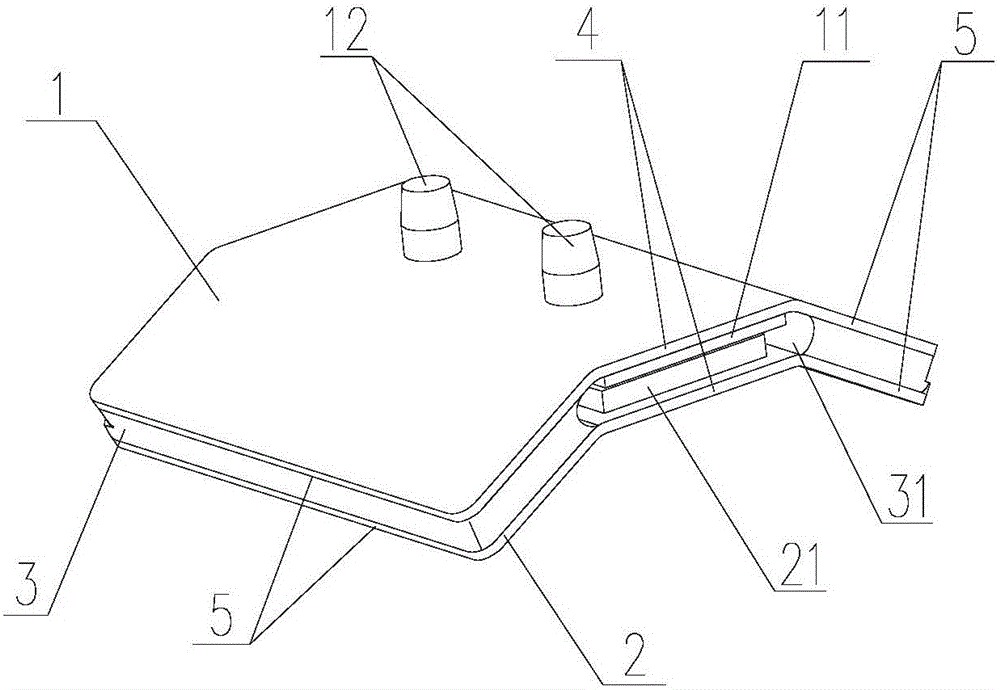

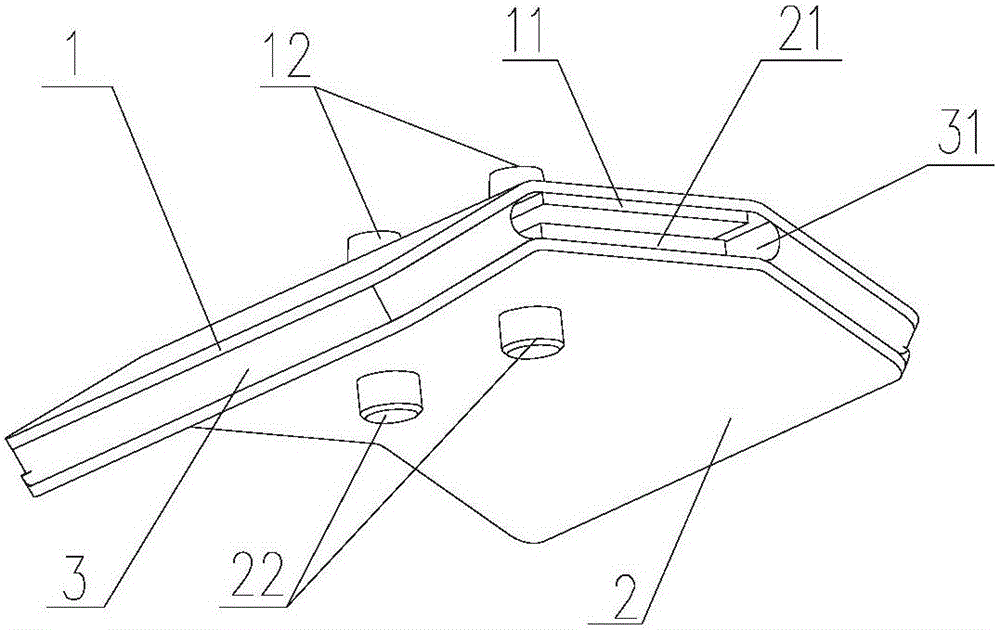

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

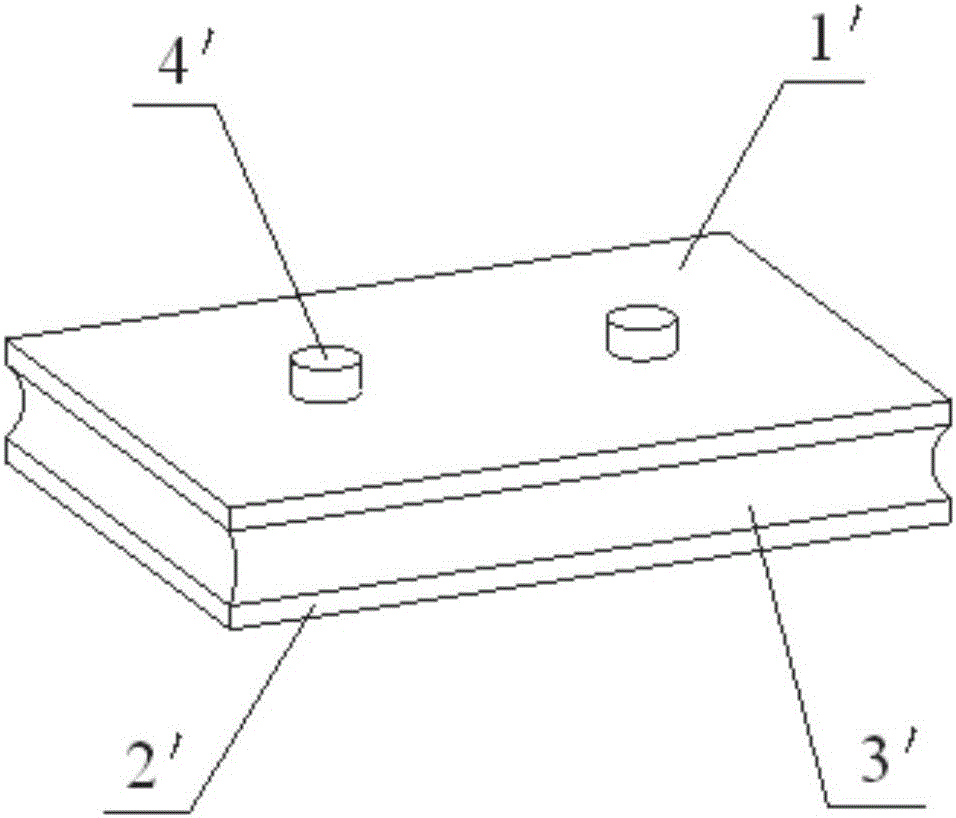

[0038] figure 1 In the shown axle box rubber pad, the rubber layer 3' acts as a spring, and the elastic potential energy of the rubber layer 3' is converted into the upper liner 1' and the lower liner during the process of its resilience buffering the above-mentioned lateral force and longitudinal force. The vibration kinetic energy of the plate 2', and when there is no damping device in the axle box rubber pad, the elastic potential energy of the rubber layer 3' attenuates very slowly, resulting in the vibration kinetic energy of the upper liner 1' and the lower liner 2' attenuation is also very slow Slow, and then the vibration between the wheel set and the side frame cannot be eliminated, resulting in the serpentine mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com