A high-speed short-side width adjustment method for continuous casting of slab continuous casting machine mold

A slab continuous caster and mold technology, applied in the field of metal casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

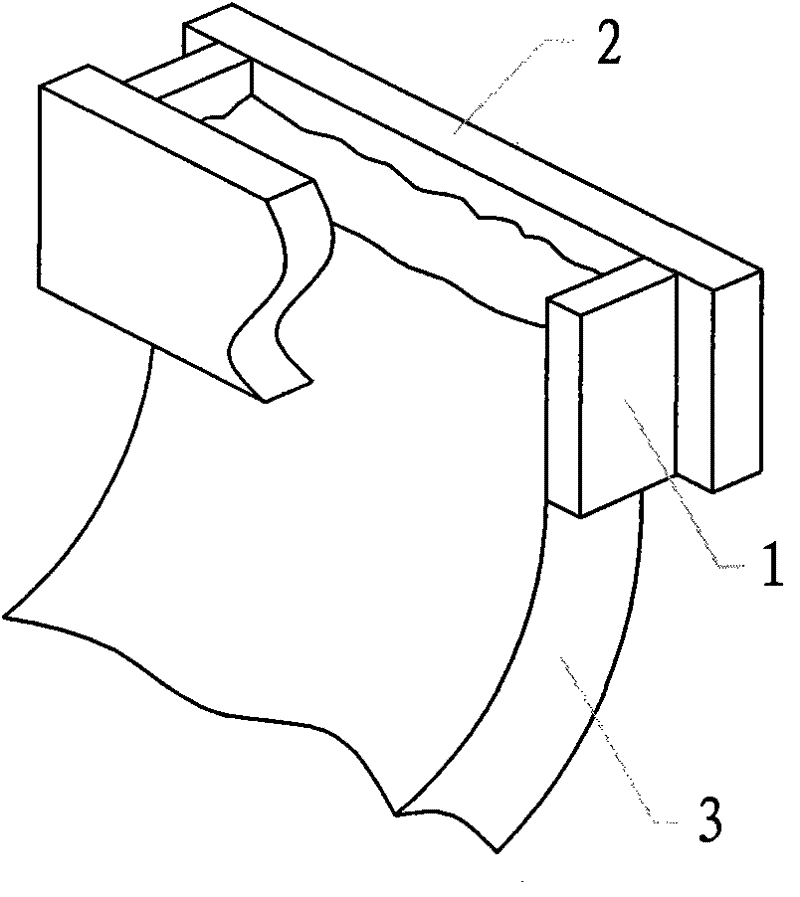

[0094] figure 1 Among them, the side plates of the crystallizer are divided into long side plates 2 and short side plates 1, which are surrounded by each other to form a rectangular frame space, and the pouring molten steel is restricted / guided by each frame of the space to form a blank shell 3 And is output from the continuous casting machine.

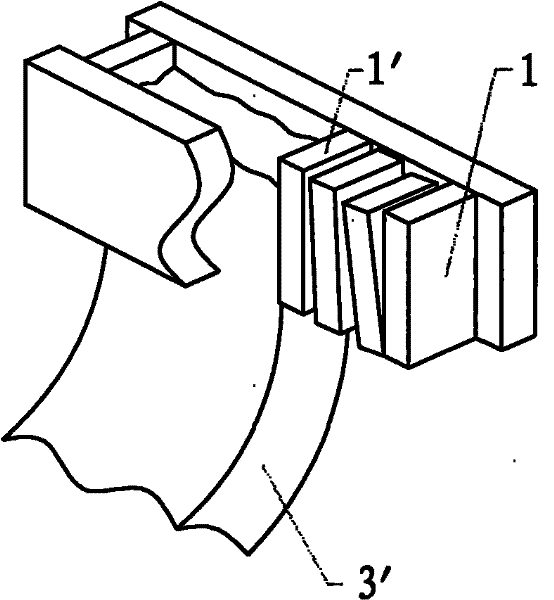

[0095] figure 2 Among them, the technology of dynamically moving the short side of the crystallizer to change its width during the steel pouring process is called short side width adjustment-cone adjustment technology.

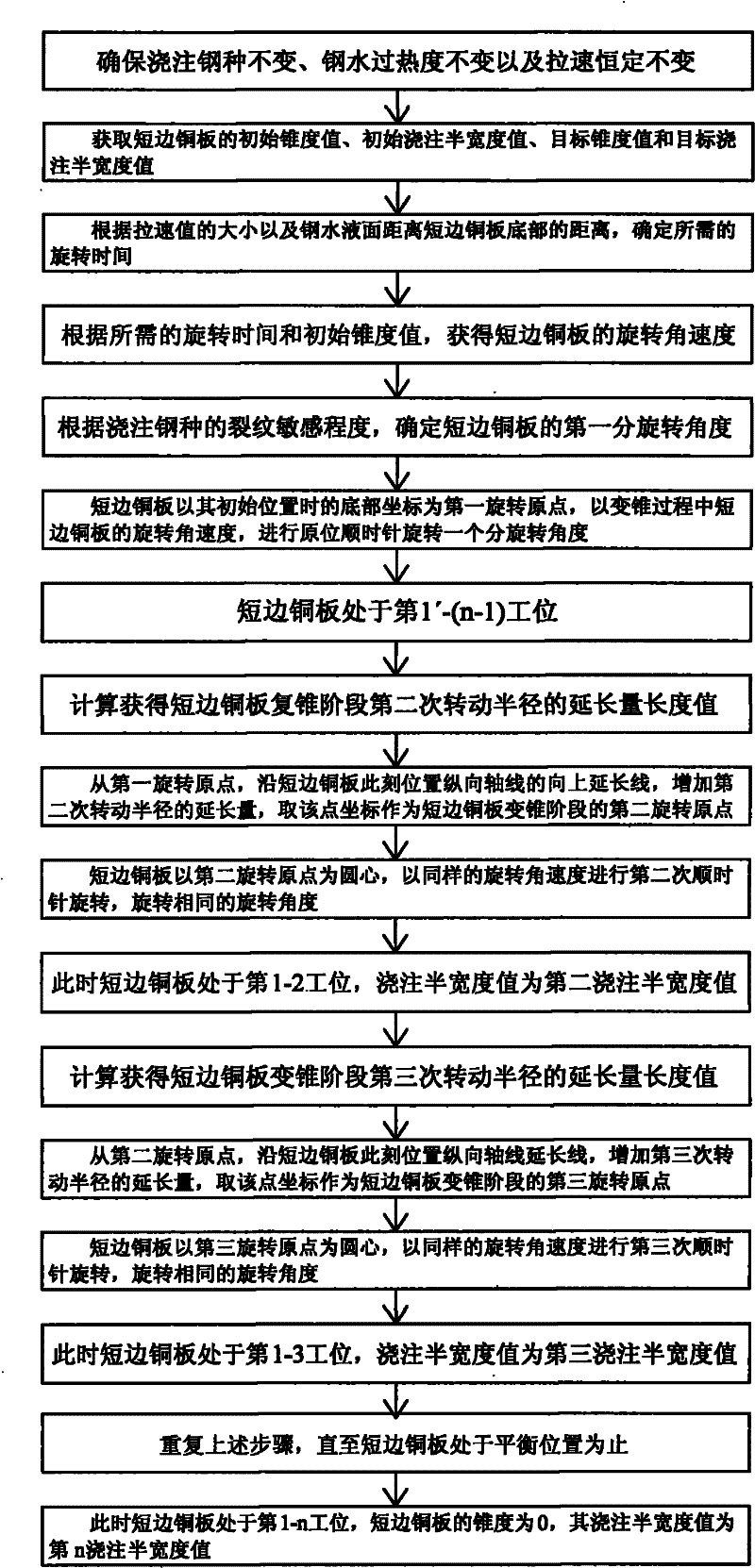

[0096]According to the technical solution of the present invention, the copper plate on the short side of the crystallizer is subjected to variable cone motion with increasing radius of rotation and compound cone motion with decreasing radius of rotation to make it move at high speed from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com