Reservoir casing perforation anti-crushing simulation test method and simulation test machine

A simulation test, anti-collapse technology, applied in the testing of machine/structural components, using stable tension/pressure to test the strength of materials, measuring devices, etc. It can improve the efficiency of oil production, overcome the high cost and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

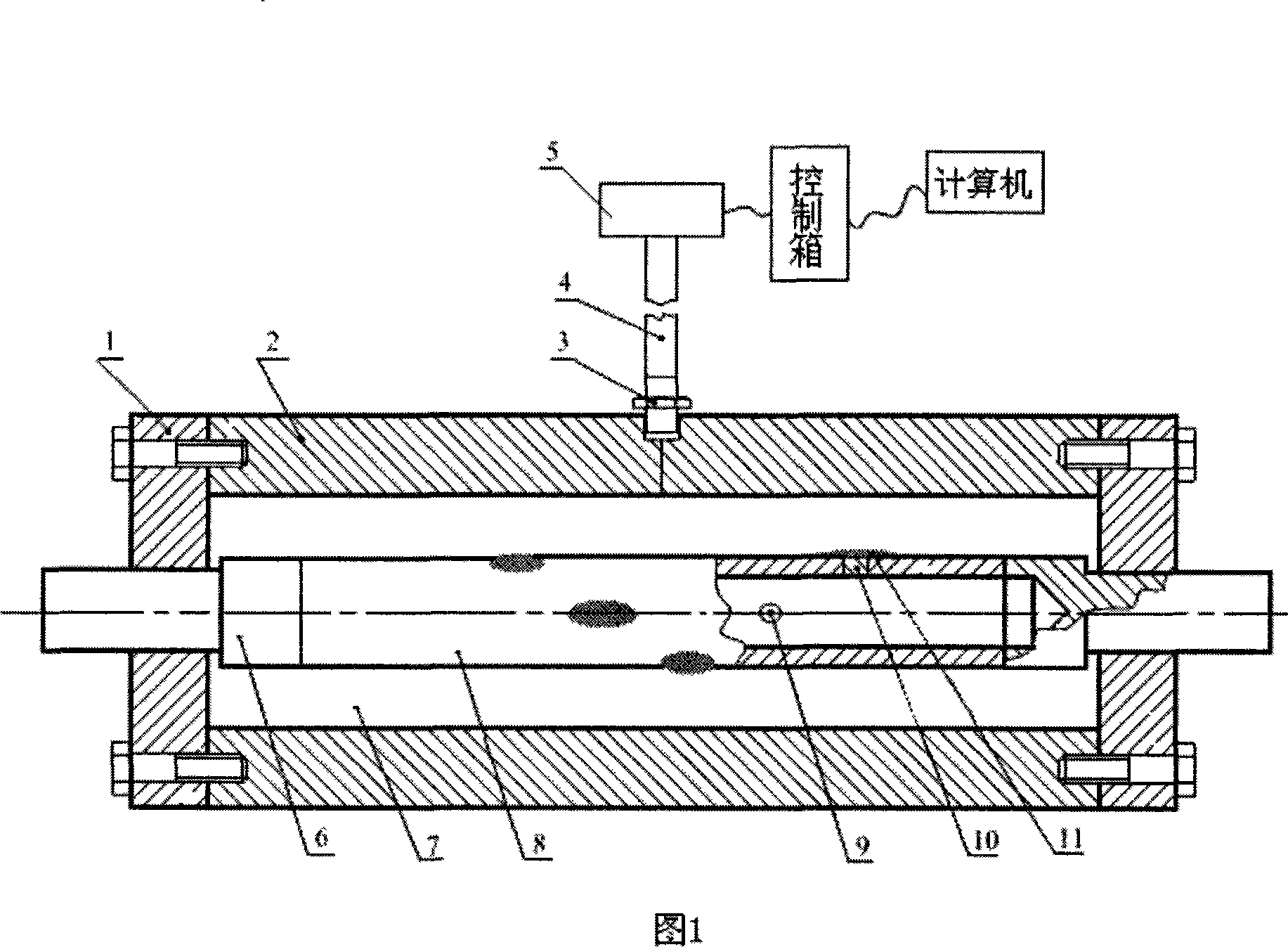

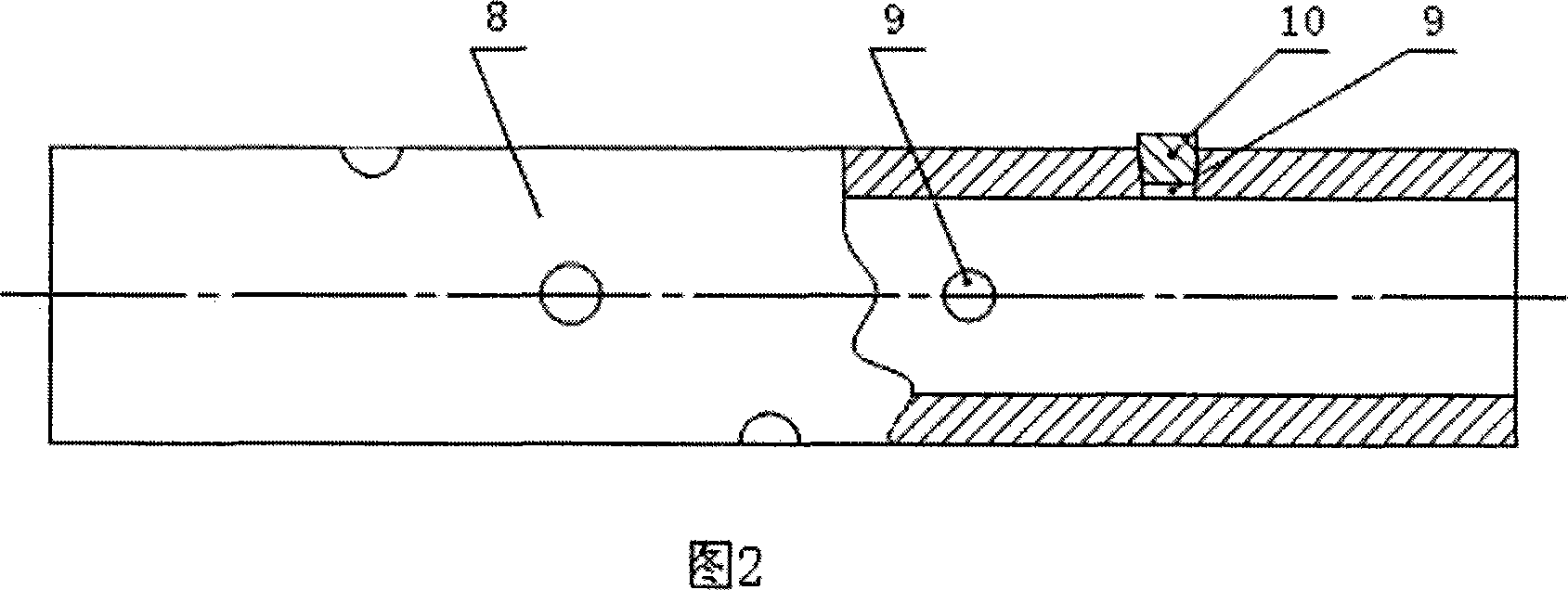

[0037]Embodiment 1: Refer to Fig. 2. Oil layer casing perforation anti-collapse simulation test machine, the pressure cylinder 2 is cylindrical, with a length of 3900mm, an inner diameter of 320mm, and a wall thickness of 160mm. There is a pressure medium injection hole on the wall of the pressure cylinder 2, and a hydraulic pressure sensor 3 is fixed on the pressure medium injection hole. The model number of hydraulic sensor 3 is MOHR267042. The inner diameter of the high-pressure conduit 4 is 3mm, and the high-pressure conduit 4 is connected to the pressure pump 5, and the model of the pressure pump 5 is MOHR30000. The hydraulic pressure sensor 3 is connected with the control box and the computer through wires. The pressure cylinder 2 should be able to withstand a maximum internal pressure of 210MPa.

[0038] Both ends of the pressure cylinder 2 are respectively fixed with plugging flanges 1 . The fixing method can be fixed by bolts. There is a sealing rubber pad betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com