Simulated downhole coal wall internal stress testing system

A testing system and technology of internal stress, applied in force/torque/work measuring instruments, measuring force, measuring devices, etc., can solve the problem that the mechanical characteristics parameters of simulated coal wall cannot be measured, adjustment signals are difficult to collect, and cutting geometric parameters and motion Difficulty parameters, etc., to achieve the effect of optimizing operating parameters and accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

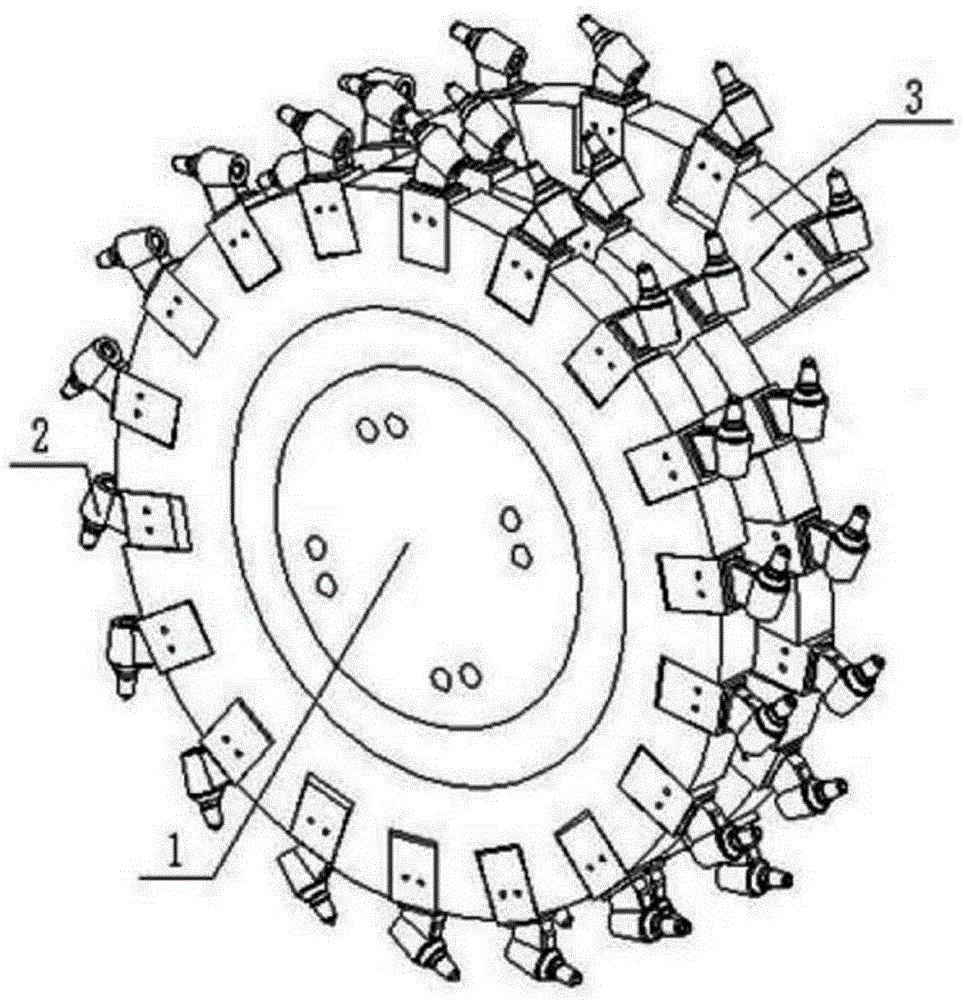

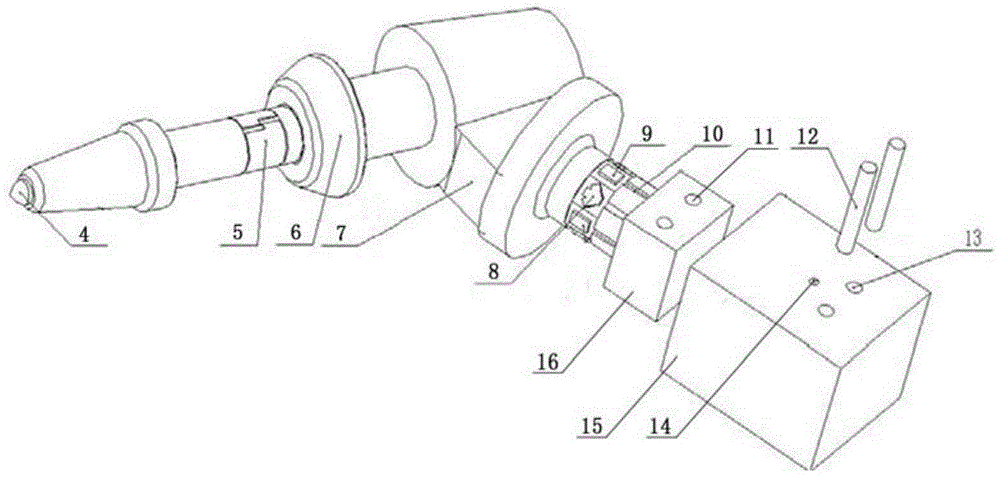

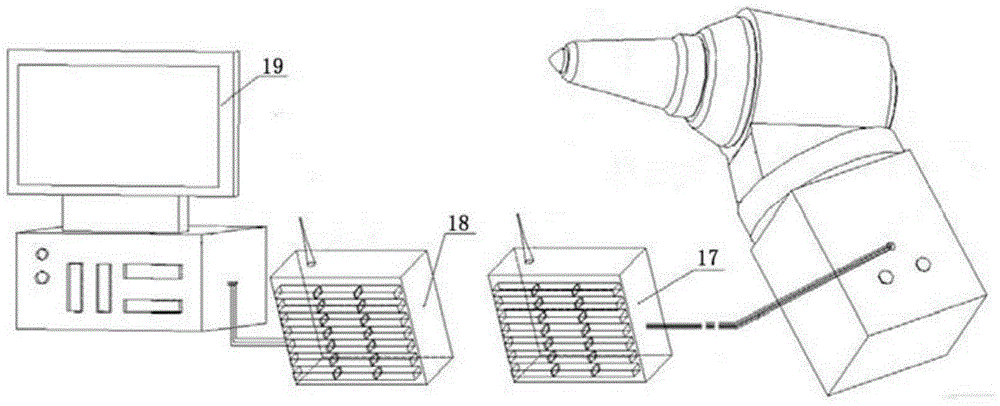

[0019] The following combination Figure 1-8 , the content of the present invention will be described in detail through specific embodiments. The simulated underground coal wall internal stress test system includes a cutting tooth force detection system, a drum torque detection system and a simulated coal wall data acquisition platform.

[0020] 1) Cutting tooth force detection system

[0021] The system includes cutting components, A / D converter, data memory, transmitting module 17, receiving module 18, display screen 19 and other components. Among them, the cutting assembly includes a spiral drum 1 and a pick unit 2 fixed on the drum 1 along the circumferential direction, and the pick unit includes a carbide head 4, a snap ring 5, a tooth sleeve 6, a tooth seat 7, a block 14, etc. Parts, the pick unit is fixed on the helical blade 3 of the drum 1 through a block. The end of the tungsten carbide head is inserted into the tooth seat and fixed by the tooth sleeve of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com