Diphase separating element, and separator, reactor and adsorption equipment of containing the element

A technology of phase separation and light components, applied in the field of two-phase separation device, fixed-bed reactor, and two-phase separation unit cylinder, which can solve the problems of single function of catalytic reaction, influence of activity, inconvenient replacement of fiber bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] The present invention will be further described in detail below in conjunction with the accompanying drawings.

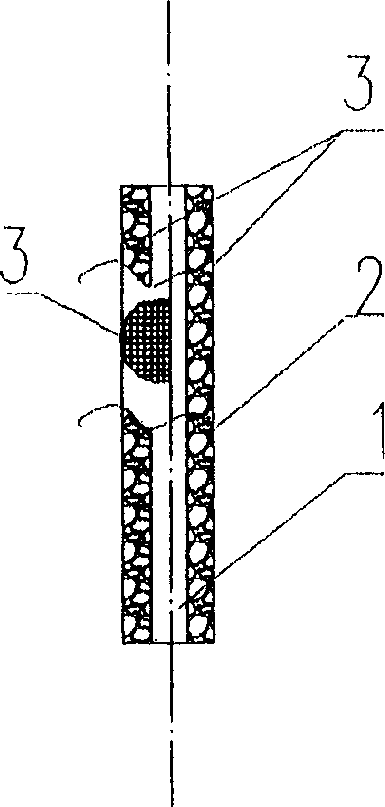

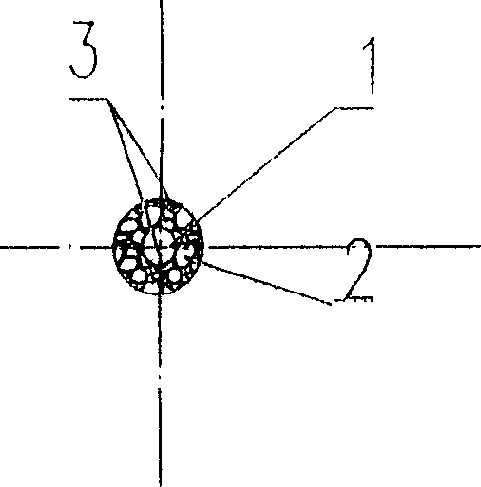

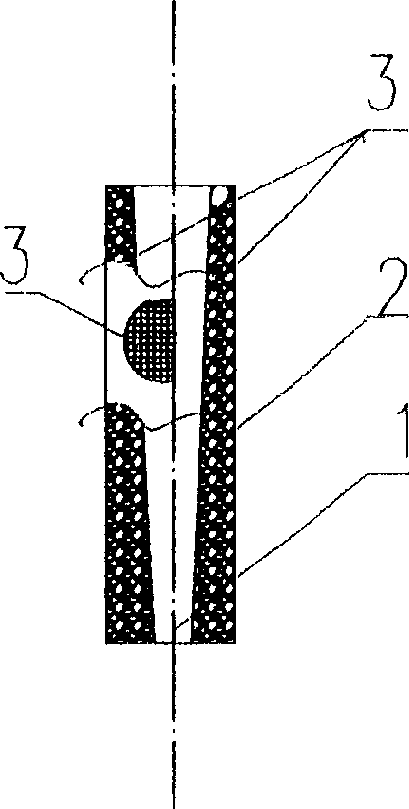

[0102] Such as figure 1 and Figure 1a As shown, the figure shows the straight cylindrical structure of the two-phase separation unit of the present invention, including the net component or light component channel 1 formed by the space in the cylinder and two mesh-like or hollow cylinders with different diameters 3 sets of solid particles 2 filled in the completed annular cavity, as can be seen from the figure, dense irregular void channels are formed between the solid particles. Solid granular matter: it can be spherical or spherical, or irregularly shaped solid granular matter; quartz sand, pebbles, metallic or non-metallic solid granular matter, or produced or used by the production process system itself Particles, such as fertilizer particles produced by the aggregate method of fertilizer production, such as coal particles screened in coal screening pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com