Coal gangue activity exciting agent and high-fluidity and high-solid-content cemented filling slurry

A technology of active activator and coal gangue, which is applied in the field of cemented filling slurry, can solve the problems of low strength, pipe plugging, and low strength of filling materials, and achieve the effects of good excitation, simple proportioning and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

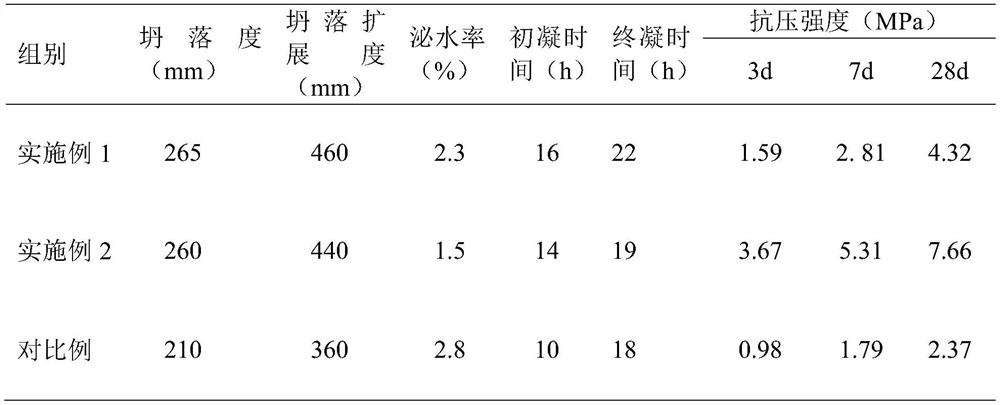

Examples

Embodiment 1

[0033] The coal gangue activity activator of this embodiment is condensed by 5.5kg of calcined limestone, 8.5kg of sodium silicate, 77kg of caustic soda, 8.3kg of dihydrate gypsum and 0.7kg of naphthalene-based water reducing agent-sodium naphthalenesulfonate formaldehyde The material was processed as follows:

[0034] Step A: Mix 5.5kg of calcined limestone, 8.5kg of sodium silicate, 77kg of caustic soda and 8.3kg of gypsum dihydrate to obtain mixed raw material A;

[0035] Step B: The mixed raw material A is ball-milled with a ball mill for 40 min to obtain the mixed raw material B; the specific surface area of the mixed raw material B reaches 380 m 3 / ㎏;

[0036] Step C: mixing raw material B and water in a ratio of 1:0.8 by mass and then placing them on a high-speed mixer and stirring for 10min, and the stirring speed of the high-speed mixer is 1100rpm; then carry out ultrasonic vibration treatment for 30min, ultrasonic frequency is 60KHz, ultrasonic wave The power is ...

Embodiment 2

[0047] The coal gangue activity activator of this embodiment is composed of 4.5kg of calcined limestone, 7.5kg of sodium silicate, 67.8kg of caustic soda, 18.8kg of hemihydrate gypsum and 1.4kg of naphthalene-based water reducing agent-sodium naphthalenesulfonate formaldehyde The condensate is obtained by the following treatment:

[0048] Step A: Mix 4.5kg of calcined limestone, 7.5kg of sodium silicate, 67.8kg of caustic soda and 18.8kg of gypsum dihydrate to obtain mixed raw material A;

[0049] Step B: The mixed raw material A is ball-milled with a ball mill for 60 min to obtain the mixed raw material B; the specific surface area of the mixed raw material B reaches 520 m 3 / ㎏;

[0050] Step C: mixing raw material B and water in a ratio of 1:0.8 by mass and then placing them on a high-speed mixer and stirring for 12min, and the stirring speed of the high-speed mixer is 1500rpm; then carry out ultrasonic vibration treatment for 33min, ultrasonic frequency is 70KHz, ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com