Composite bonding low-temperature constructional castable refractory

A technology of refractory castables and refractory raw materials, which is applied in the field of compound combined low-temperature construction refractory castables, can solve the problems of slow hardening and low strength of castables, and achieve the effect of improving slow hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

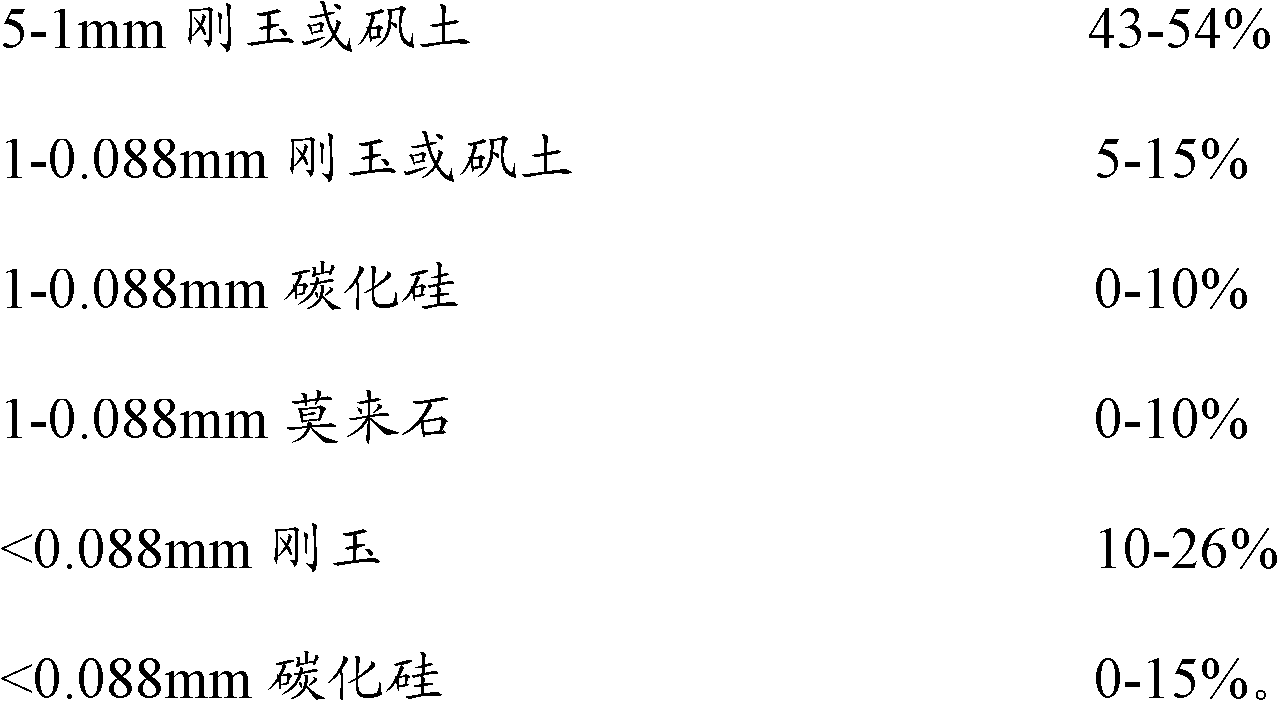

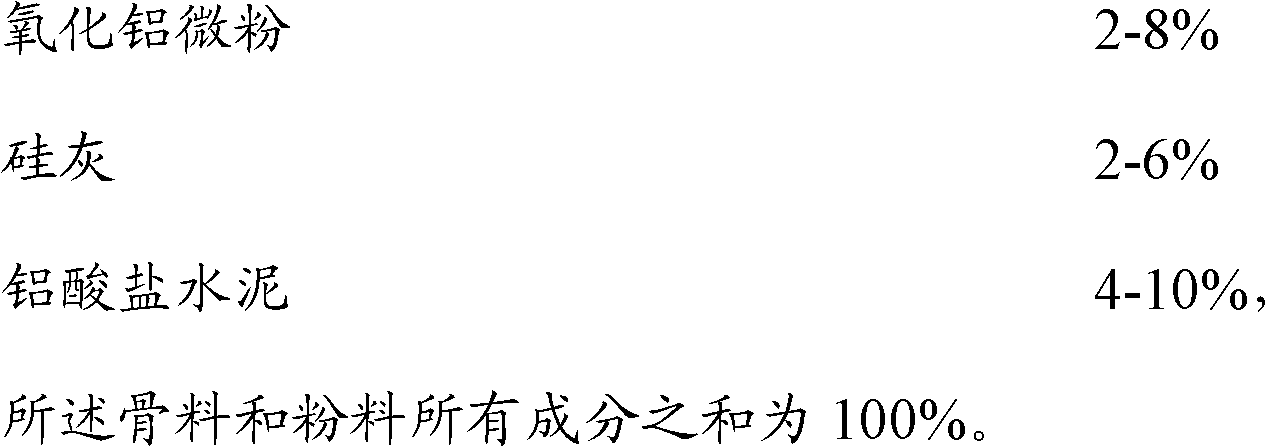

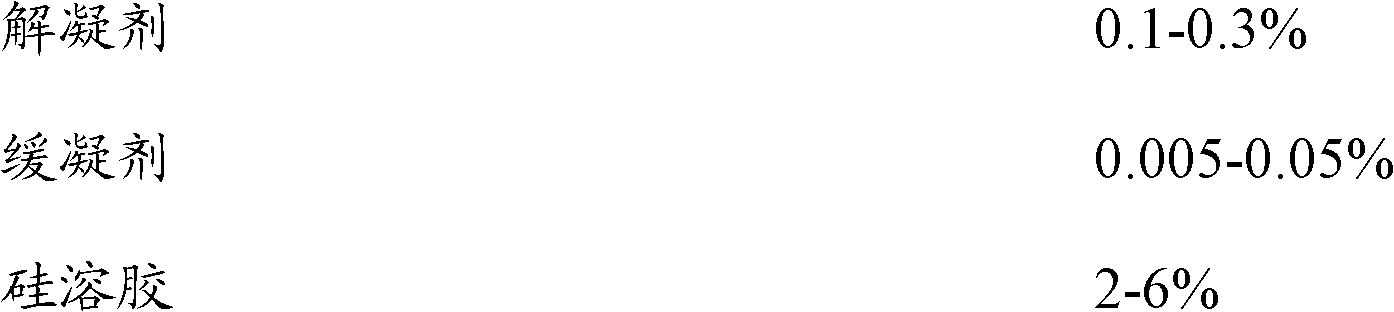

[0056] The weight ratio is: 5-1mm fused corundum 53%, 1-0.088mm fused corundum 9%, 1-0.088mm silicon carbide 5%, <0.088mm fused corundum 14%, <0.088mm silicon carbide 5%, 5% alumina micropowder, 4% silica fume, 5% aluminate cement, 0.2% sodium hexametaphosphate, 0.02% citric acid, 4% silica sol with a concentration of 30%, and 3% water.

[0057] According to the above ratio, the solid raw materials are weighed and blended, and then poured into the mixer; then the specified silica sol and water are added, and the test body is made after stirring, pouring, transportation, pouring, vibration, demoulding, and curing. Physical properties were tested after heat treatment. When curing at about 5°C, the demoulding time of the castable is about 20 hours.

[0058] The measured physical properties are: 110℃×24h drying: flexural strength 10.1MPa, compressive strength 61.3MPa; 1100℃×3h drying: flexural strength 16.9MPa, compressive strength 156.1MPa, line change -0.12%; 1350℃ ×3h drying:...

Embodiment 2

[0061] The weight ratio is: 5-1mm high bauxite 50%, 1-0.088mm high bauxite 13%, 1-0.088mm mullite 4%, <0.088mm high bauxite 18%, alumina micropowder 5 %, silica fume 3%, aluminate cement 7%, sodium hexametaphosphate 0.2%, citric acid 0.01%, silica sol with a concentration of 40% 4%, water 4%.

[0062] According to the above ratio, the solid raw materials are weighed and blended, and then poured into the mixer; then the specified silica sol and water are added, and the test body is made after stirring, pouring, transportation, pouring, vibration, demoulding, and curing. Physical properties were tested after heat treatment. When curing at about 5°C, the initial setting time of the castable and the demoulding time are about 14 hours.

[0063] The measured physical properties are: 110℃×24h drying: flexural strength 13.3MPa, compressive strength 105.3MPa; 1100℃×3h drying: flexural strength 18.2MPa, compressive strength 130.0MPa, line change -0.18%; 1350℃ ×3h drying: flexural stre...

Embodiment 3

[0066] The weight ratio is: 5-1mm fused corundum 43%, 1-0.088mm high alumina bauxite 5%, 1-0.088mm silicon carbide 10%, 1-0.088mm mullite 10%, <0.088mm fused corundum 10%, <0.088mm silicon carbide 10%, alumina micropowder 2%, silica fume 6%, aluminate cement 4%, sodium pyrophosphate 0.1%, tartaric acid 0.05%, silica sol with a concentration of 25% 6%, water 1%.

[0067] According to the above ratio, the solid raw materials are weighed and blended, and then poured into the mixer; then the specified silica sol and water are added, and the test body is made after stirring, pouring, transportation, pouring, vibration, demoulding, and curing. Physical properties were tested after heat treatment. When curing at about 5°C, the demoulding time of the castable is about 20 hours.

[0068]The measured physical properties are: 110℃×24h drying: flexural strength 10.5MPa, compressive strength 62.3MPa; 1100℃×3h drying: flexural strength 17.0MPa, compressive strength 158.2MPa, line change -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com