Method for calibrating X-ray detector on basis of auxiliary module

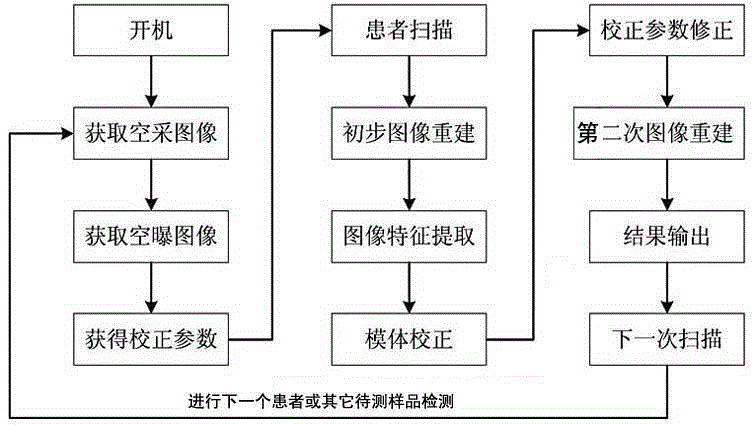

A calibration method and detector technology, which is applied in the fields of radiological diagnostic instruments, medical science, diagnosis, etc., can solve the problem that the parameters during calibration and the parameter gains during use cannot be guaranteed to be completely consistent, and the geometric information of the sample to be measured is unknown and difficult to obtain. Correct parameters and other issues to achieve the effect of improving the accuracy of secondary reconstruction, reducing cost and manufacturing difficulty, and improving service life and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

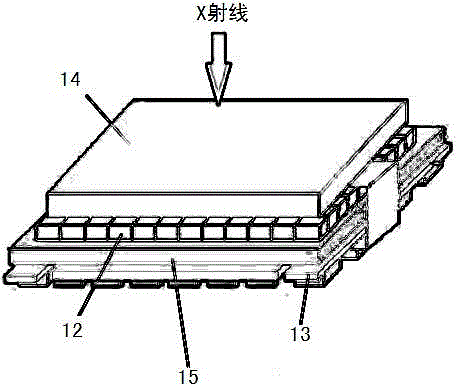

[0037] An X-ray detector based on an auxiliary phantom is characterized in that it includes an auxiliary phantom for detection together with a sample to be tested.

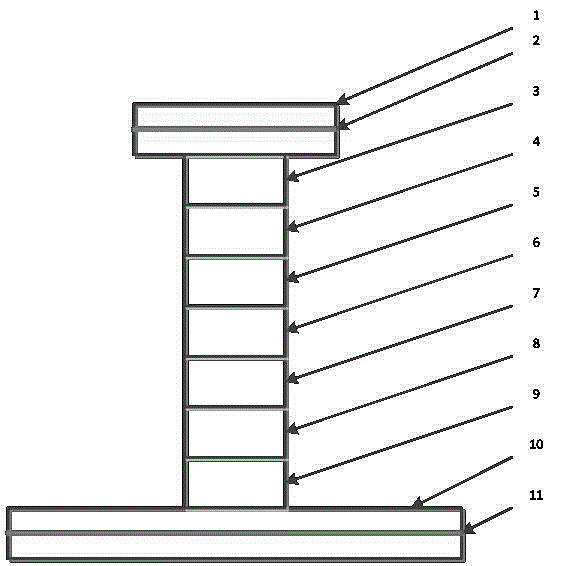

[0038] refer to figure 2 As shown, the auxiliary phantom includes a nylon buckle finger strap 1 and a nylon buckle wrist strap 10 on the upper and lower end faces, a flexible metal wire 2 and a flexible metal wire 11 wound around the nylon buckle finger strap 1 and the nylon buckle wrist strap 10 respectively, And be arranged on a plurality of standard density modules between nylon buckle finger belt 1 and nylon buckle wristband 10, present embodiment is provided with seven, and label is figure 2In 3 to 9, the standard density module is formed as a whole by bonding, and the standard density module is joined with a nylon buckle finger strap 1 and a nylon buckle wrist s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com