One-time formed inflatable hollow tire and manufacturing method thereof

A production method and hollow technology, applied in the direction of non-pneumatic tires, tire parts, tires, etc., can solve the problems of complex production, poor shock absorption, poor air tightness, etc., to reduce the weight of the carcass, improve shock absorption, reduce The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

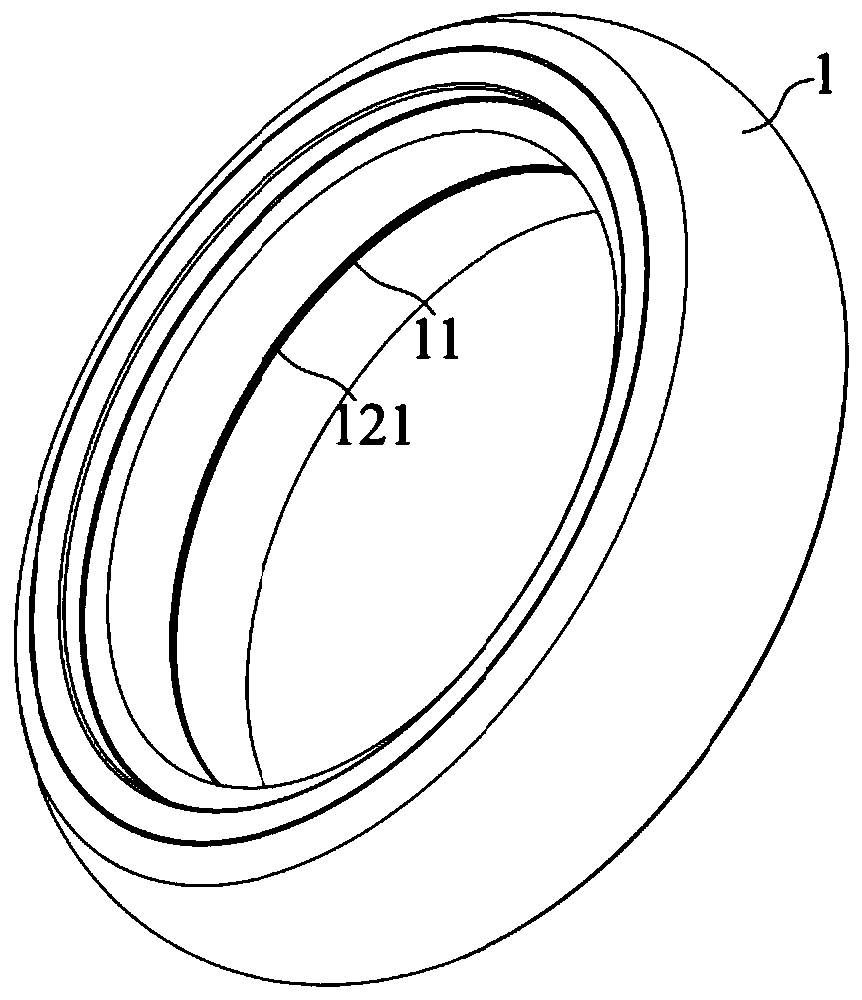

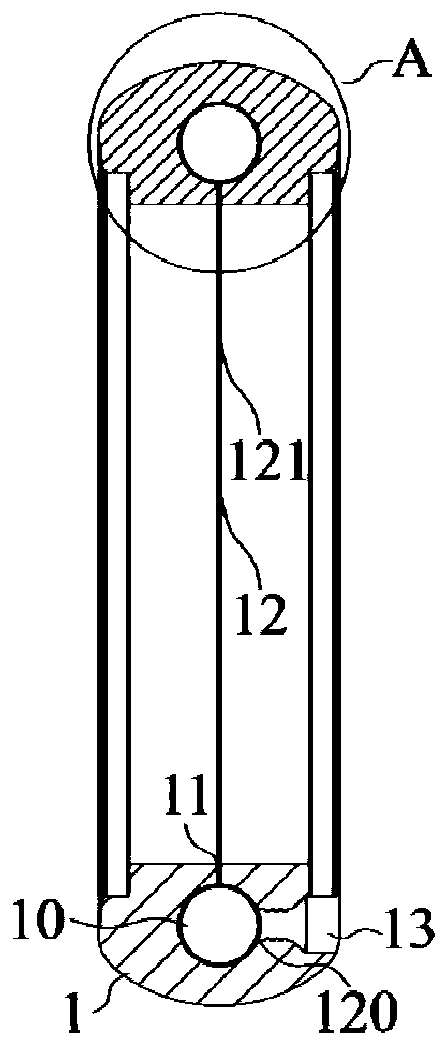

[0070] Such as figure 1 with figure 2 As shown, the one-time forming inflatable hollow tire of this embodiment includes a carcass 1, and further includes:

[0071] The cavity structure 10 is opened in the carcass 1 along the circumferential direction, and a hollow cavity is formed in the carcass 1;

[0072] The opening structure 11 is a groove opened on the inner ring surface of the carcass 1 along the circumferential direction, and the opening structure 11 communicates the cavity structure 10 with the outside; and

[0073] The airtight layer 12 is composed of an airtight layer 120 formed on the surface of the cavity structure 10 and an airtight layer 121 that closes the opening structure 11;

[0074] The valve mounting hole 13 is opened on the side of the carcass 1 and connects the cavity structure 10 with the carcass 1.

[0075] Hollow cavities of hollow tires are mostly molded by placing the mold core in the cavity of the molded tire when the tire is made. After the tire cavity is m...

Embodiment 2

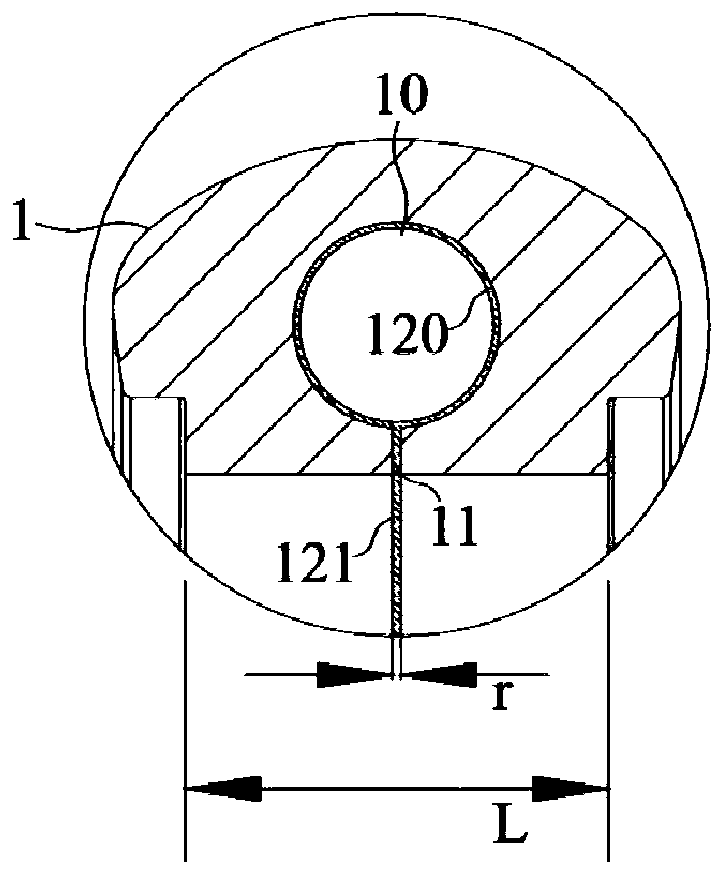

[0081] Such as Figure 5 As shown, the one-time forming inflatable hollow tire of this embodiment is further improved on the basis of Embodiment 1. The opening width r of the opening structure 11 gradually increases from the cavity structure 10 to the inner ring of the carcass 1.

[0082] In the tire of this embodiment, the shape of the opening structure 11 from the cross section of the carcass 1 shows a triangular shape from the cavity structure 10 to the inner ring of the carcass 1. The opening structure 11 of this embodiment makes the mold core The take-out operation is easy, and the cavity structure 10 and the opening structure 11 in the carcass 1 are not damaged, and the yield of the hollow tire is high.

Embodiment 3

[0084] Such as Figure 4 As shown, the one-time forming inflatable hollow tire of this embodiment is further improved on the basis of embodiment 1. The opening width r of the opening structure 11 gradually changes from the cavity structure 10 to the inner ring direction of the carcass 1. Decrease.

[0085] In the tire of this embodiment, the shape of the opening structure 11 from the cross section of the carcass 1 is shown as an inverted triangle from the cavity structure 10 to the inner ring of the carcass 1. In the opening structure 11 of this embodiment, after the rim is installed, The two sides of the inner side of the body 1 are compressed to cooperate with the opening structure 11 to form a locking effect. On the one hand, the fastening effect between the rim and the carcass 1 is enhanced, and the safety of the tire is increased. On the other hand, after the rim is compressed The opening structure 11 is more tightly closed and cooperates with the airtight layer 121 to furth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com