Damping arrangement for reducing combustion chamber pulsations in a gas turbine system

A technology of vibration reduction device and combustion chamber, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., and can solve the problems that the combustion chamber cannot be easily used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

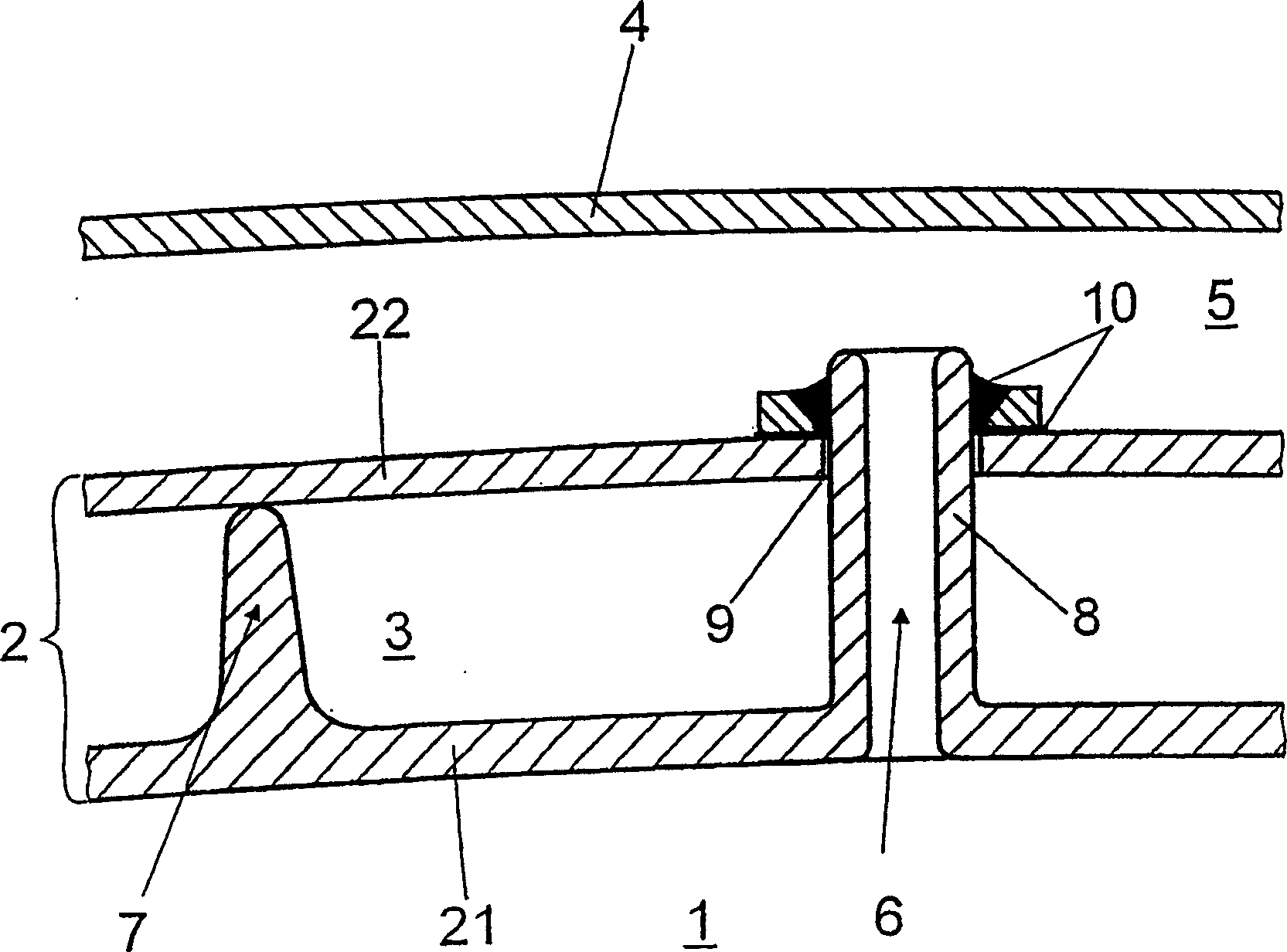

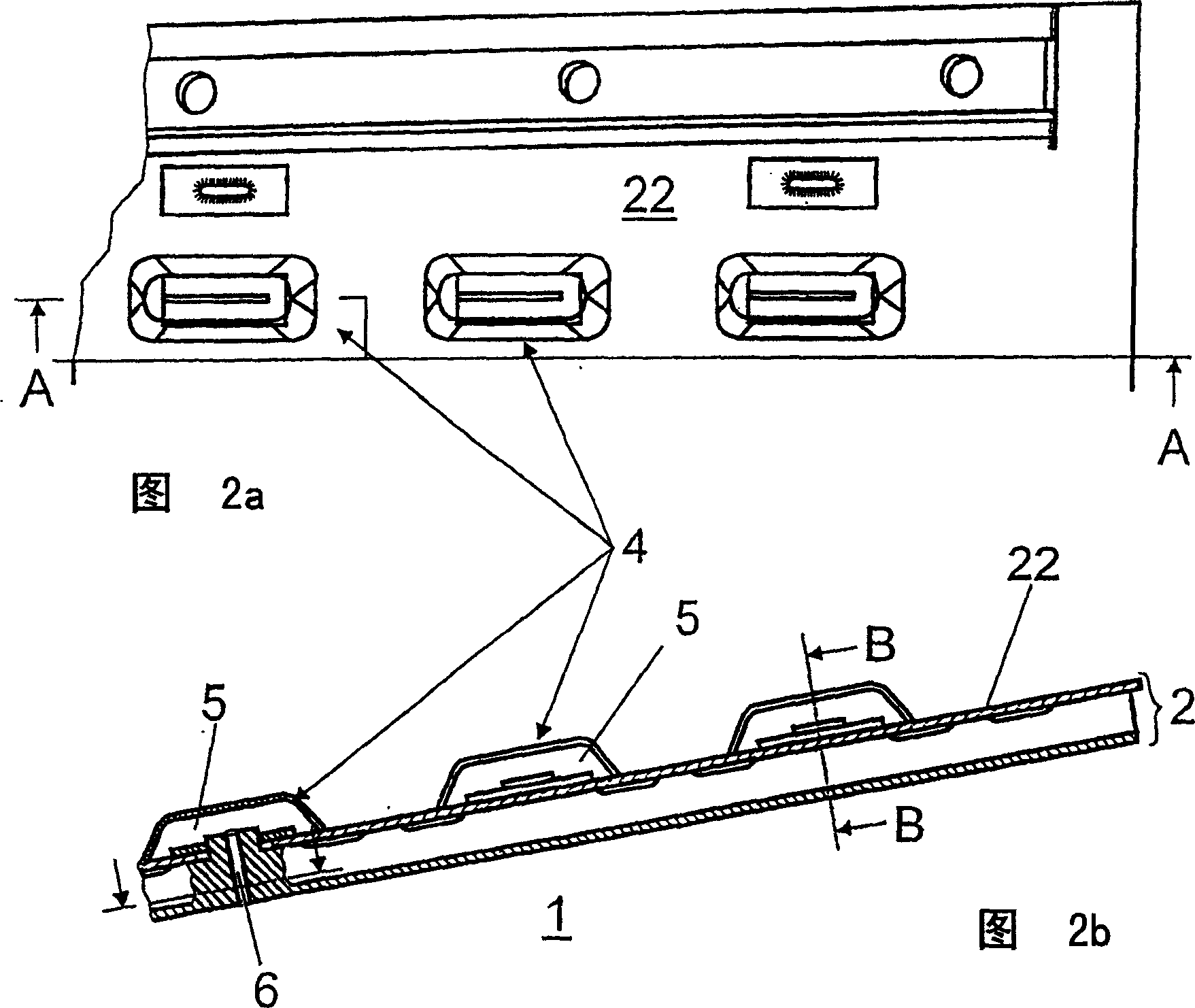

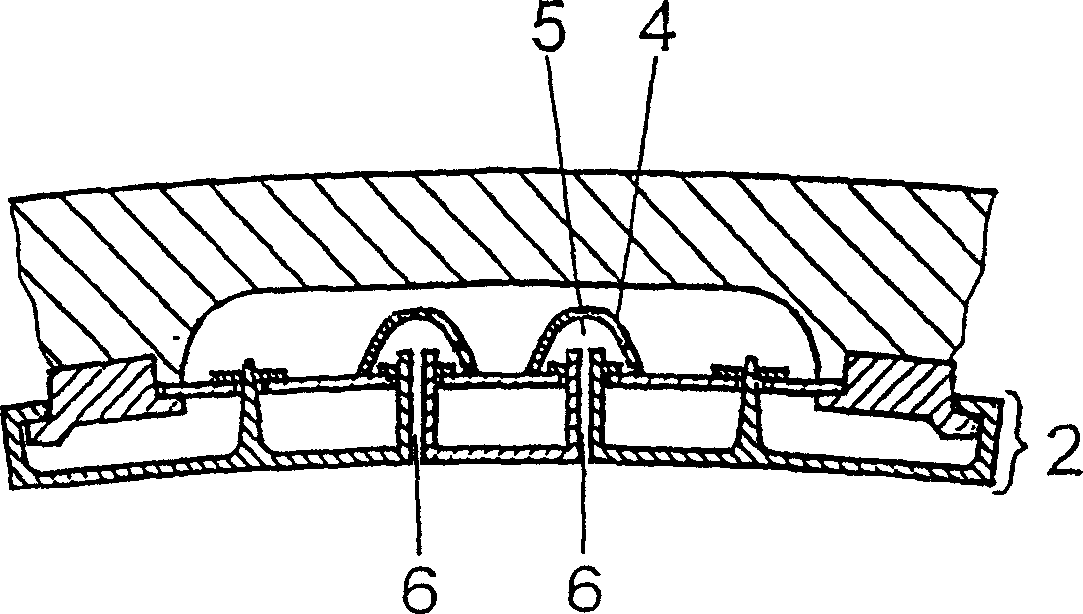

[0031] figure 1 A vibration damping device is shown in cross-section for reducing resonances in a combustion chamber 1 surrounded by a double-walled combustion chamber wall 2 with an outer wall part 22 and an inner wall part 21 encloses an intermediate chamber 3 in a gas-tight manner, into which cooling air can be fed in order to convectively cool the combustion chamber wall 2 and in particular the inner wall part 21 .

[0032] On the side of the outer wall part 22 facing away from the combustion chamber 1 there is a third wall part 4 which together with the outer wall part 22 encloses a gas-tight space, the so-called resonance space or absorption space 5 . Via a connecting line 6 in the form of a connecting tube, the absorption space 5 is directly connected to the combustion chamber 1 and at the same time an acoustically effective connection is created between the combustion chamber 1 and the absorption space 5 . In order to acoustically effectively damp the combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com