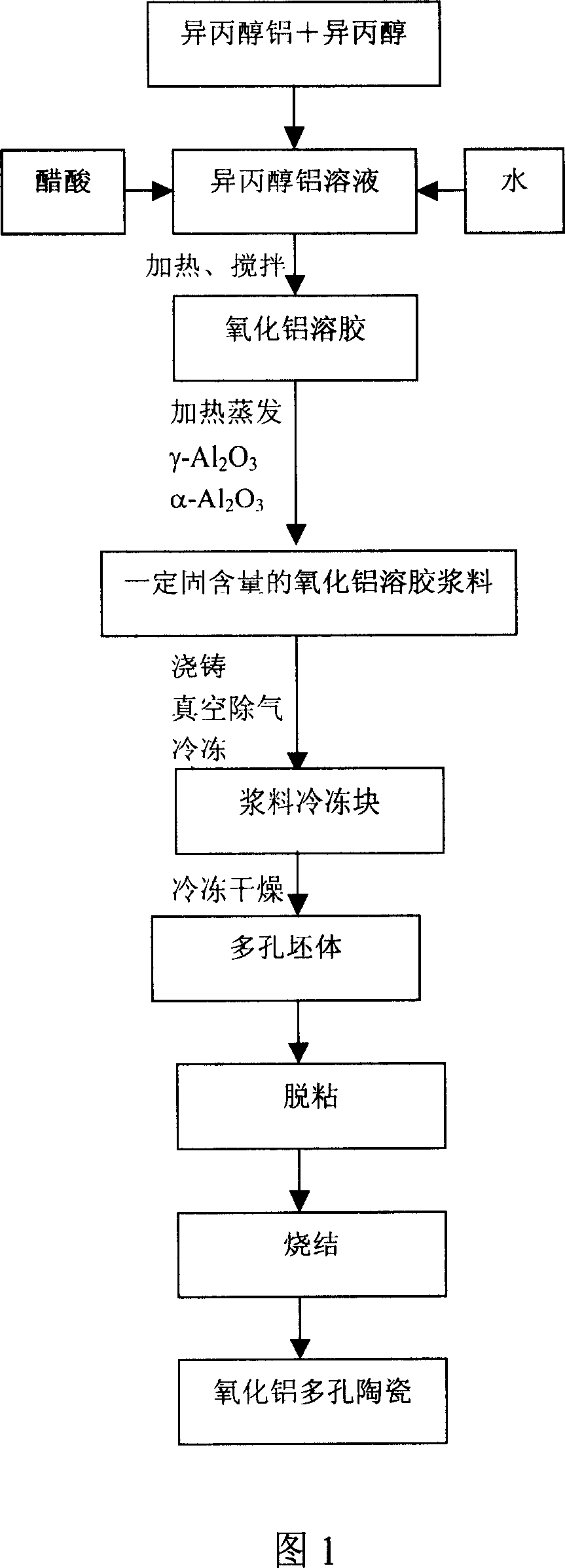

Method for preparing alumina porous ceramic using gelatin wrapping-freeze drying process

A drying process, sol-gel technology, applied in the field of porous ceramics, to achieve the effect of convenient casting, good performance controllability and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

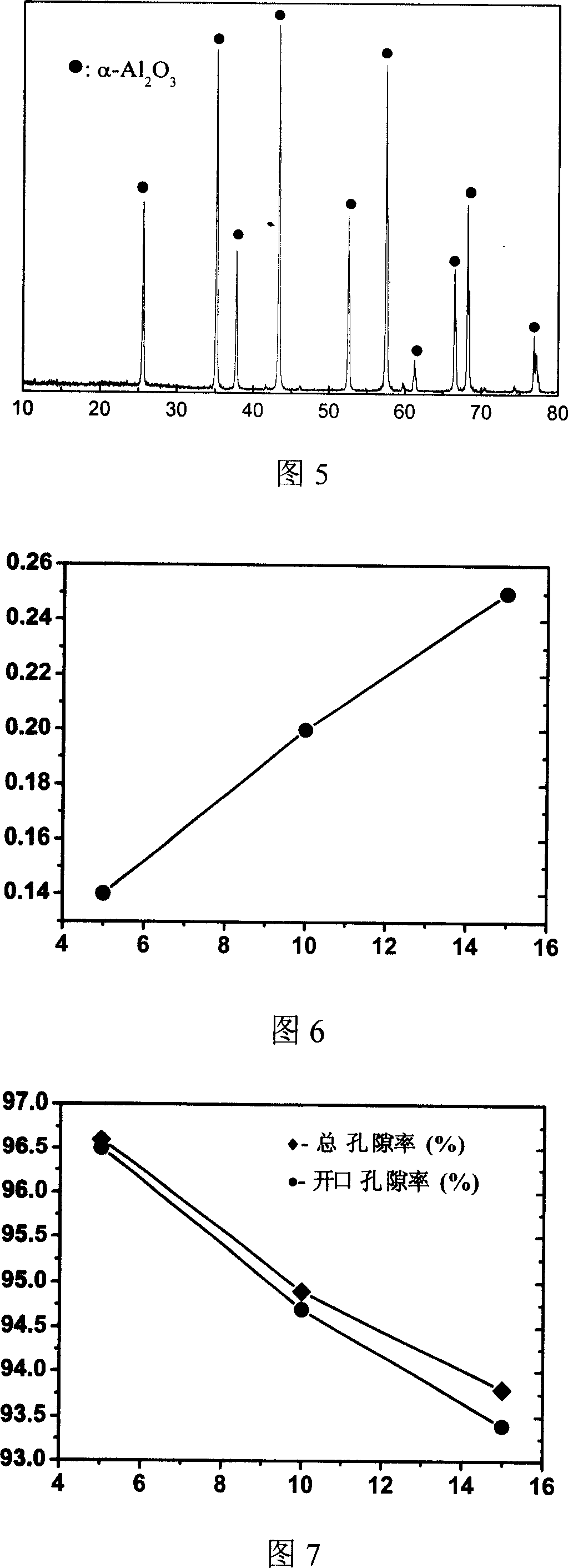

[0029] The present invention will be further described below through specific implementation, but the present invention is by no means limited to the examples, and the process examples are shown in the following table:

[0030]

Example

Solid content adjustment method

Content

binder containing

Amount (wt%)

when freeze-dried

time (hours)

Pressure (Pa)

temperature(℃)

1

heating evaporation

5

3

48

20

60

2

heating evaporation

10

3

48

20

60

[0031] 3

heating evaporation

15

3

48

20

60

4

Add γ-Al 2 O 3

10

3

48

20

60

5

Add γ-Al 2 O 3

15

3

48

20

60

6

Add γ-Al 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com