Building cement slab casting device

A cement board and building technology, applied in the direction of cement mixing device, supply device, clay preparation device, etc., can solve the problems of low efficiency, unavoidable control of the continuous and intermittent outflow of well-mixed cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

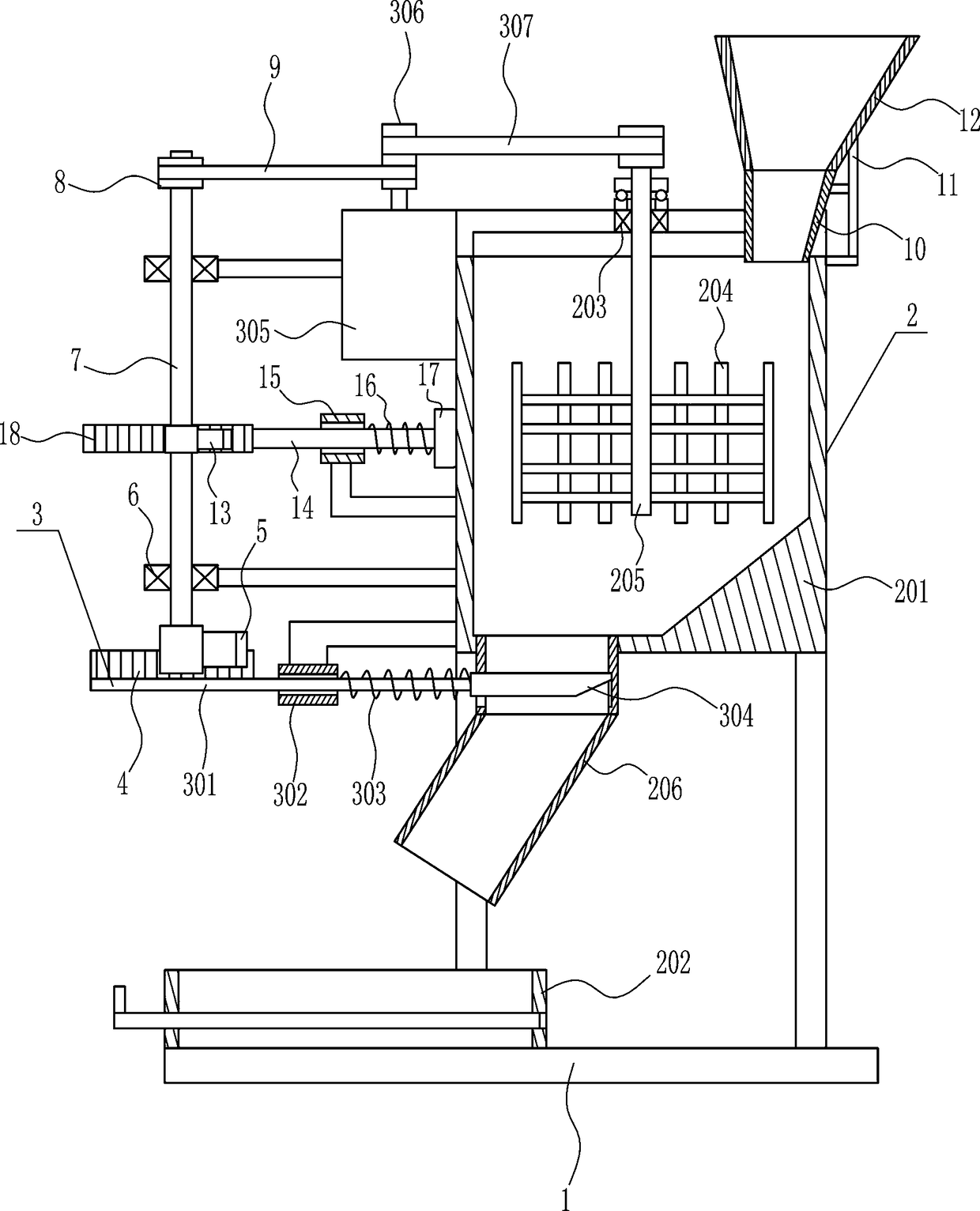

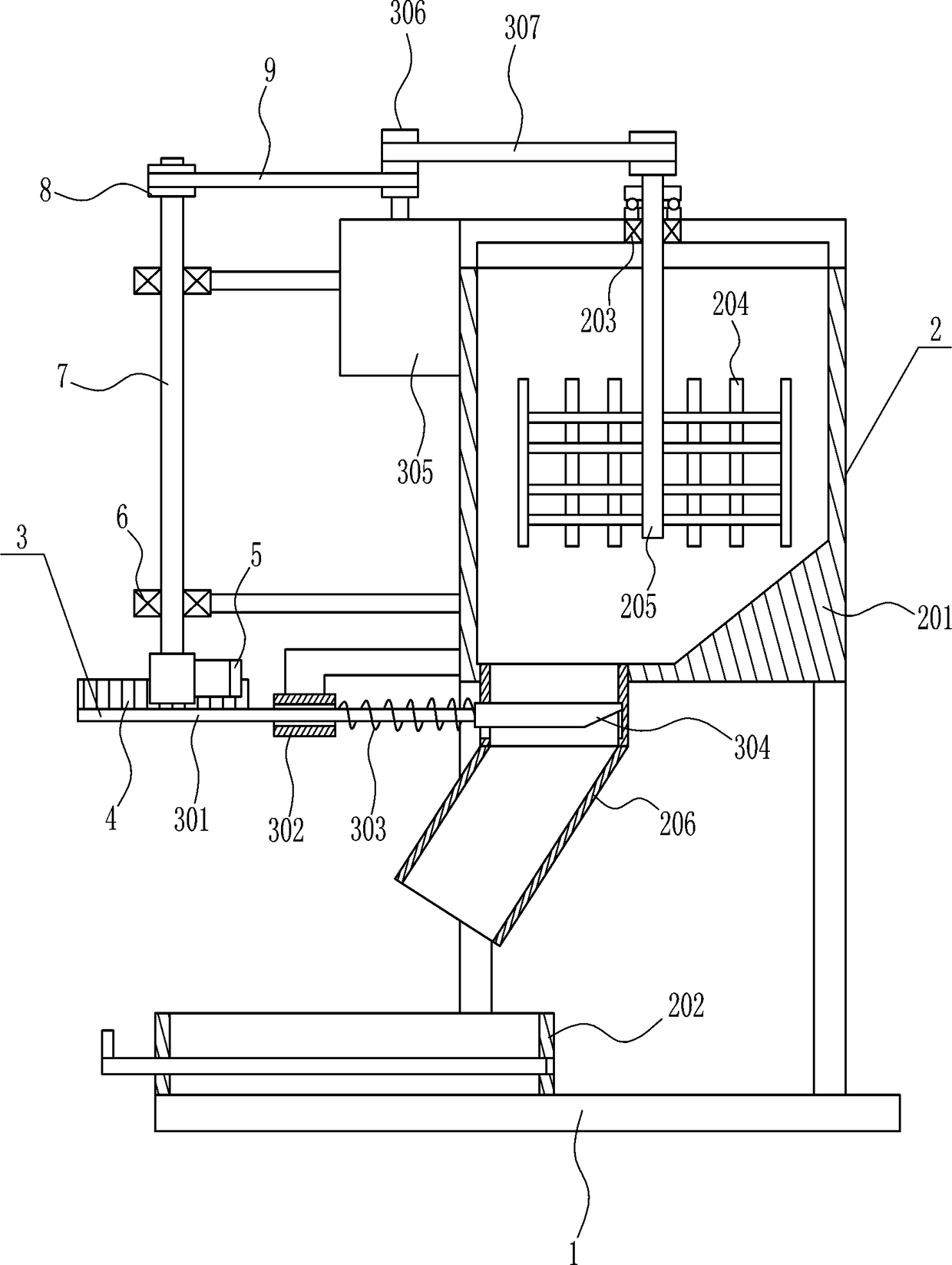

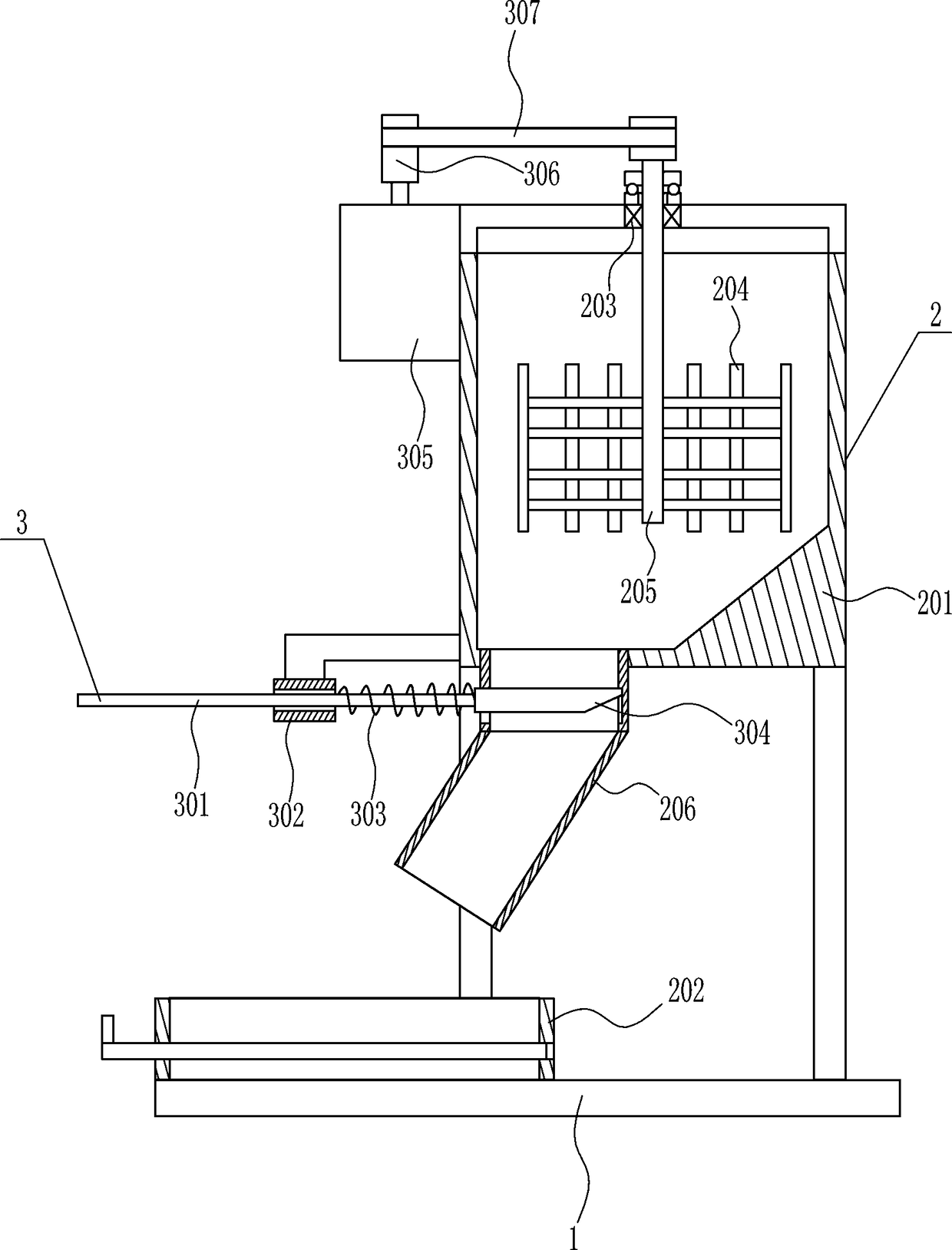

[0029] A construction cement board casting device, such as Figure 1-5 As shown, it includes a bottom plate 1 , a stirring mechanism 2 and a driving mechanism 3 , the top of the bottom plate 1 is connected with the stirring mechanism 2 , and the upper side of the stirring mechanism 2 is connected with the driving mechanism 3 .

Embodiment 2

[0031] A construction cement board casting device, such as Figure 1-5 As shown, it includes a bottom plate 1 , a stirring mechanism 2 and a driving mechanism 3 , the top of the bottom plate 1 is connected with the stirring mechanism 2 , and the upper side of the stirring mechanism 2 is connected with the driving mechanism 3 .

[0032] The stirring mechanism 2 includes a stirring box 201, a casting frame 202, a first bearing seat 203, a stirring rod 204, a first rotating rod 205, and a discharge hopper 206. There is a casting frame 202, a first bearing seat 203 is connected to the top of the mixing box 201, a first rotating rod 205 is connected inside the first bearing seat 203, and a stirring rod 204 is evenly connected to the lower side of the first rotating rod 205, and the stirring rod 204 is located at the stirring Inside the box 201 , a hopper 206 is connected to the bottom of the stirring box 201 .

Embodiment 3

[0034] A construction cement board casting device, such as Figure 1-5 As shown, it includes a bottom plate 1 , a stirring mechanism 2 and a driving mechanism 3 , the top of the bottom plate 1 is connected with the stirring mechanism 2 , and the upper side of the stirring mechanism 2 is connected with the driving mechanism 3 .

[0035] The stirring mechanism 2 includes a stirring box 201, a casting frame 202, a first bearing seat 203, a stirring rod 204, a first rotating rod 205, and a discharge hopper 206. There is a casting frame 202, a first bearing seat 203 is connected to the top of the mixing box 201, a first rotating rod 205 is connected inside the first bearing seat 203, and a stirring rod 204 is evenly connected to the lower side of the first rotating rod 205, and the stirring rod 204 is located at the stirring Inside the box 201 , a hopper 206 is connected to the bottom of the stirring box 201 .

[0036] The driving mechanism 3 includes a first slide bar 301, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com