RDX Composition and Process for Its Manufacture

a technology of composition and rdx, applied in the field of rdx composition, can solve the problems of efi bridge explosion, system generally unsuitable for use outside the laboratory, and not widely used direct nitration method today

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

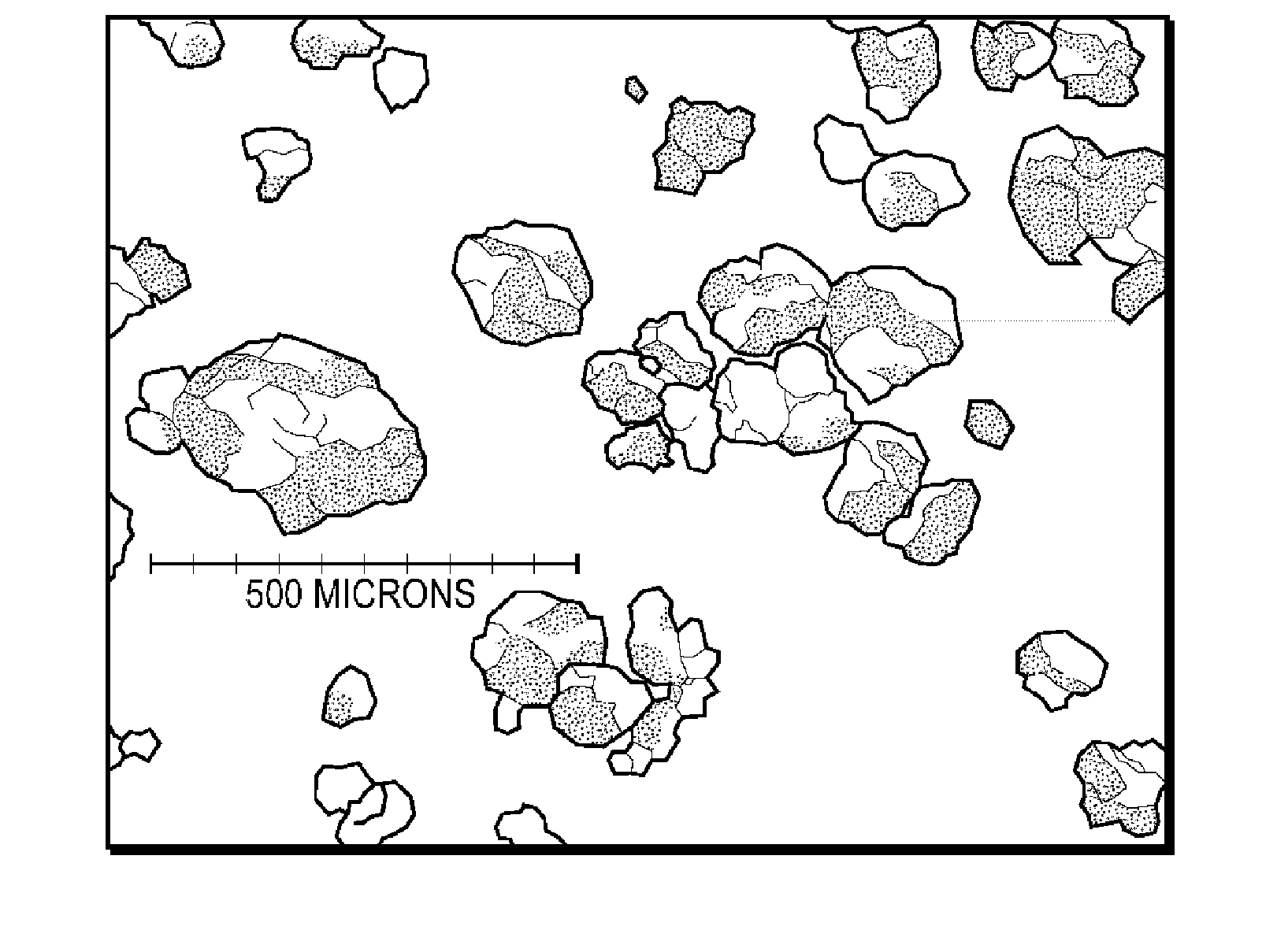

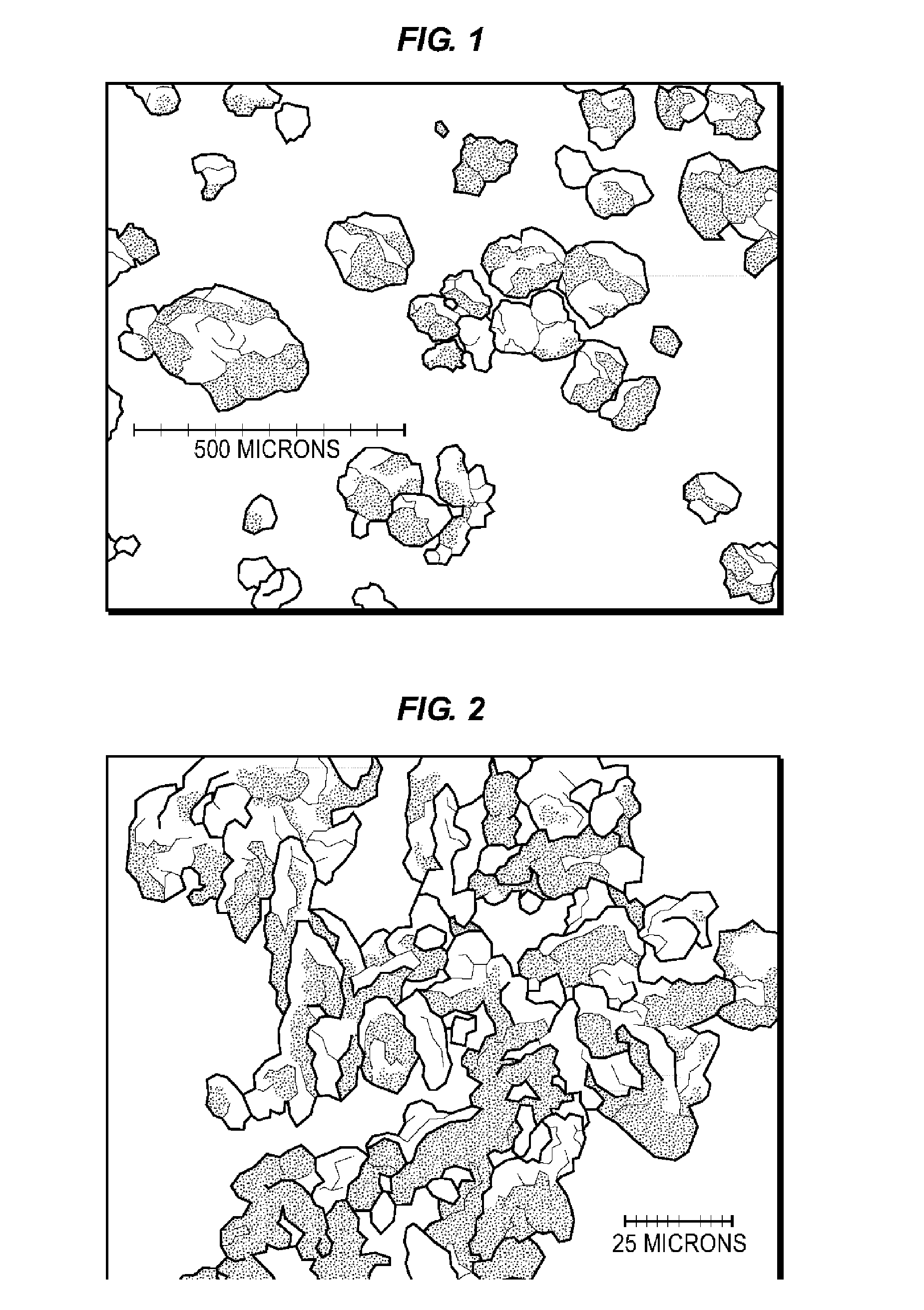

[0031] RDX crystals were prepared by crash precipitation. Type B RDX was dissolved in acetone to make a 10% by weight solution. A large excess of deionized water was added to this solution with vigorous stirring to precipitate fine particle size RDX. The precipitated RDX crystals were filtered from the liquid and washed. The resulting RDX was dried at 50-55° C. overnight in a drying oven. The measured BET surface area of the precipitated RDX was in excess of 1.2 m2 / g. When examined by light microscope, the RDX crystals appeared to be polycrystalline and orthorhombic. However, when the crystal density of the crash-precipitated RDX was checked by helium pyconometer, the crystal density was found to be 1.69 g / cm3, which is significantly different than the starting material (ca. 1.80-1.82 g / cm3).

[0032] The RDX crystals were successfully detonated in a low-energy exploding foil initiator (LEFI) at 72 mJ (1300 volts, 0.085 μF).

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com