High-gurney-energy low-vulnerability PBX explosive and preparation method thereof

A technology of fragility and explosives, applied in the field of high Gurney energy and low fragility PBX explosives and its preparation, can solve the problems of difficulty in improving the safety performance of explosives, high sensitivity, poor safety performance, etc., and achieve high efficiency The effects of damage safety, high safety, and excellent casting rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

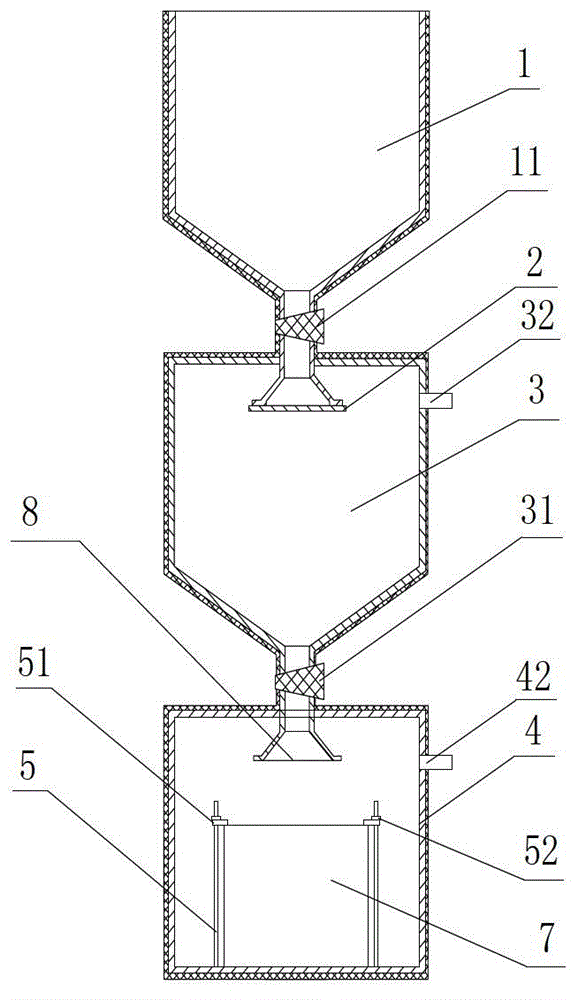

Image

Examples

Embodiment 1

[0038] The high Gurney energy low fragility PBX explosive consists of the following components by weight:

[0039] HMX, 90 parts; wherein the particle size distribution of HMX particles is as follows: Coarse particle HMX: the particle size range is 0.125-0.60mm, accounting for 65-75% of the total HMX content, and the particle size range is 0.25-0.60mm. Less than 60% of the coarse particle content; fine particle HMX: particle size ≤0.05mm, accounting for 25-35% of the total HMX content, of which the particle size ≤0.045mm content is not less than 97% of the fine particle content.

[0040] Binder: HTPB, 4.3 parts;

[0041] Desensitizer: WAX, 2.74 parts;

[0042] Plasticizer: DOS, 2.5 parts;

[0043] Curing agent: TDI, 0.46 parts.

[0044] The preparation method of high Gurney energy low fragility PBX explosive is as follows:

[0045] (1) Ingredients: weighed according to the above parts by weight.

[0046] (2) Material mixing:

[0047]The first batch of feeding and kneadin...

Embodiment 2

[0064] The high Gurney energy low fragility PBX explosive consists of the following components by weight:

[0065] HMX, 90 parts, wherein the particle size distribution of HMX particles is as follows: coarse particle HMX: the particle size range is 0.125-0.60mm, accounting for 65-75% of the total HMX content, and the particle size range is 0.25-0.60mm. Less than 60% of the coarse particle content; fine particle HMX: particle size ≤ 0.05mm, accounting for 25-35% of the total HMX content, of which the particle size ≤ 0.045mm content is not less than 97% of the fine particle content;

[0066] Binder: HTPB, 4.5 parts;

[0067] Desensitizer: WAX, 2.7 parts;

[0068] Plasticizer: DOS, 2.3 parts;

[0069] Curing agent: TDI, 0.5 parts.

[0070] The preparation method of the high Gurney energy and low fragility PBX explosive of this embodiment is the same as that of embodiment 1.

Embodiment 3

[0072] The high Gurney energy low fragility PBX explosive consists of the following components by weight:

[0073] HMX, 90 parts; wherein the particle size distribution of HMX particles is as follows: coarse particle HMX: the particle size range is 0.125-0.60mm, accounting for 65-75% of the total HMX content, and the particle size range is 0.25-0.60mm. Less than 60% of the coarse particle content; fine particle HMX: particle size ≤ 0.05mm, accounting for 25-35% of the total HMX content, of which the particle size ≤ 0.045mm content is not less than 97% of the fine particle content;

[0074] Binder: HTPB, 4.5 parts;

[0075] Desensitizer: WAX, 3 parts;

[0076] Plasticizer: DOS, 2 parts;

[0077] Curing agent: TDI, 0.5 parts.

[0078] The preparation method of the high Gurney energy and low fragility PBX explosive of this embodiment is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com