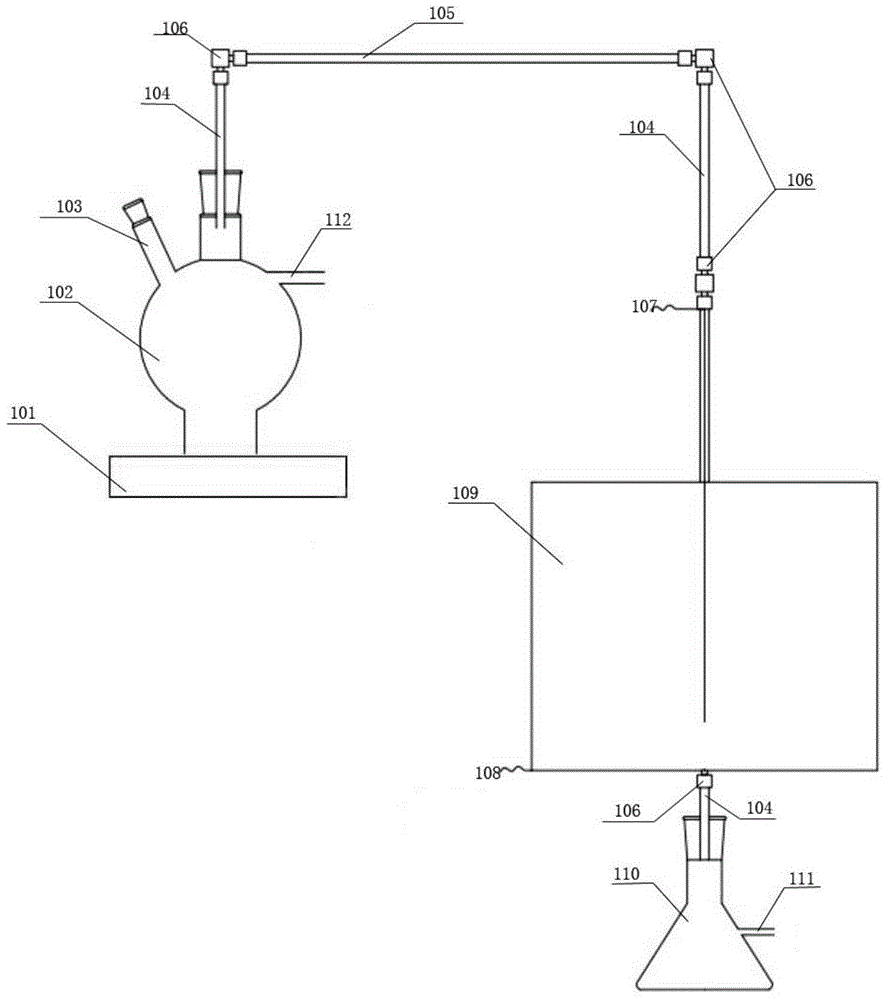

Method and device for preparing nanometer-eutectic energetic material

A nano-collection device technology, applied in the field of preparation of nano-scale eutectic energetic materials, can solve the problems of laboratory level, particle agglomeration, environmental pollution, etc., achieve mild and easy-to-control reaction conditions, wide range of preparation, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

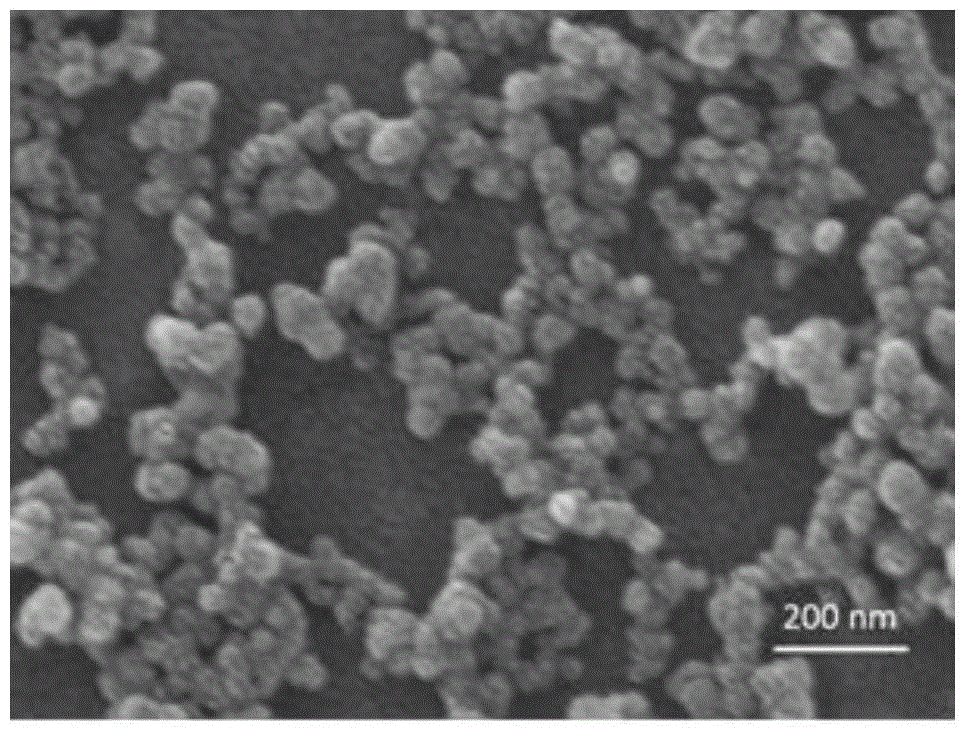

Embodiment 1

[0030]Dissolve the mixture of energetic materials 0.5mol CL-20 and 0.5mol HMX in 100mol distilled water, stir and dissolve to prepare a solution, then put the solution into an ultrasonic container, turn on the temperature gradient heating furnace to make the temperature reach the predetermined temperature (maximum The temperature is 200°C, the lowest temperature is 60°C, forming a gradient temperature environment), nitrogen is continuously fed into the ultrasonic container, the ultrasonic nebulizer is turned on, and the solution in which the energetic materials CL-20 and HMX are dissolved is ultrasonically turned into small mist droplets, nitrogen Carry the small mist droplets to a temperature gradient heating furnace for heating. At this time, the solvent liquid (distilled water in this embodiment) in the mist droplets gradually evaporates, and the CL-20 and HMX in the mist droplets start to eutectic, and the nitrogen gas continues to pass. Load the mist droplets containing eu...

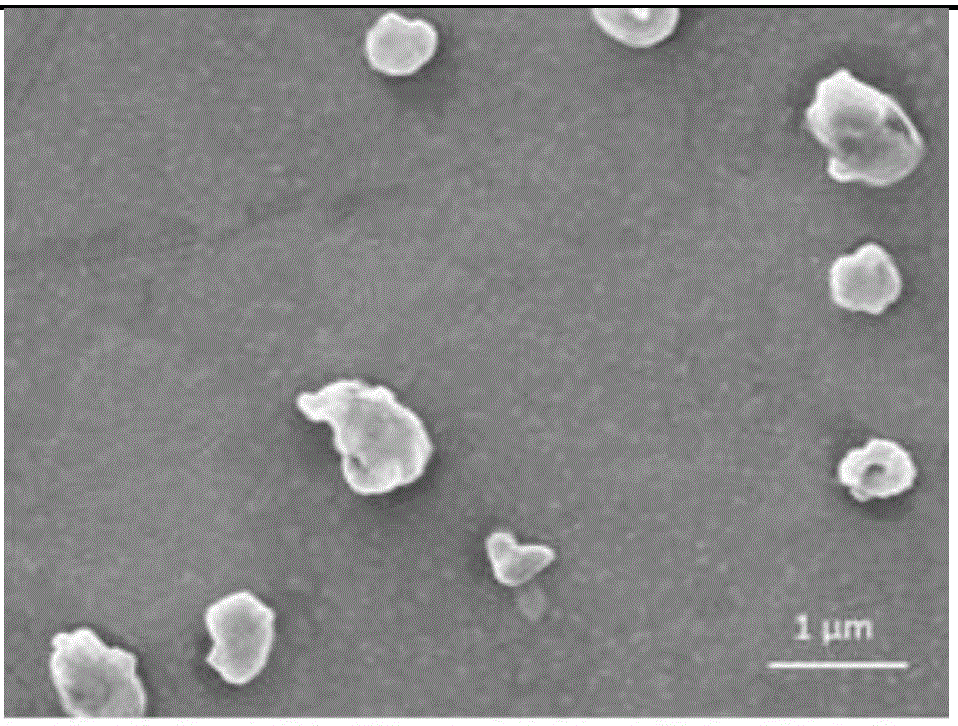

Embodiment 2

[0033] Dissolve energetic materials 0.4mol CL-20 and 0.6mol RDX in 50mol acetone, stir and dissolve to prepare a solution, then put the solution into an ultrasonic container, turn on the temperature gradient heating furnace to make the temperature reach the predetermined temperature (maximum temperature 200°C, the lowest temperature is 60°C, forming a gradient temperature environment), continuously inject argon into the ultrasonic container, turn on the ultrasonic nebulizer, and ultrasonically dissolve the solution containing energetic materials CL-20 and HMX into small mist droplets. The argon gas transfers the small mist to the temperature gradient heating furnace for heating. At this time, the acetone in the mist gradually evaporates, and the energetic material in the mist begins to eutectic, and the argon continues to carry the mist containing the eutectic crystal. To the high-voltage electrostatic field, the distance between the positive and negative electrodes of the high...

Embodiment 3

[0035] Dissolve the mixture of energetic materials 0.5mol CL-20 and 0.5mol NTO in 1mol absolute ethanol, stir and dissolve to prepare a solution, then put the solution into an ultrasonic container, turn on the temperature gradient heating furnace to make the temperature reach the predetermined temperature (The highest temperature is 200°C, the lowest temperature is 60°C, forming a gradient temperature environment), continuously inject nitrogen gas into the ultrasonic container, turn on the ultrasonic nebulizer, and ultrasonically transform the solution in which energetic materials are dissolved into small mist droplets, and the nitrogen gas will spray the mist The droplets are transferred to the temperature gradient heating furnace for heating. At this time, the water vapor in the droplets gradually evaporates, and the energetic materials in the droplets begin to eutectic, and the nitrogen gas continues to carry the droplets containing eutectic crystals to the high-voltage elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com