Pattern color spraying method for plastic yarn-loop floor mat

A wire loop floor mat and plastic technology, applied in printing and other directions, can solve the problems of backward technology, low production efficiency, poor pattern color quality, etc., and achieve the effect of good color effect, high production efficiency and clear pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

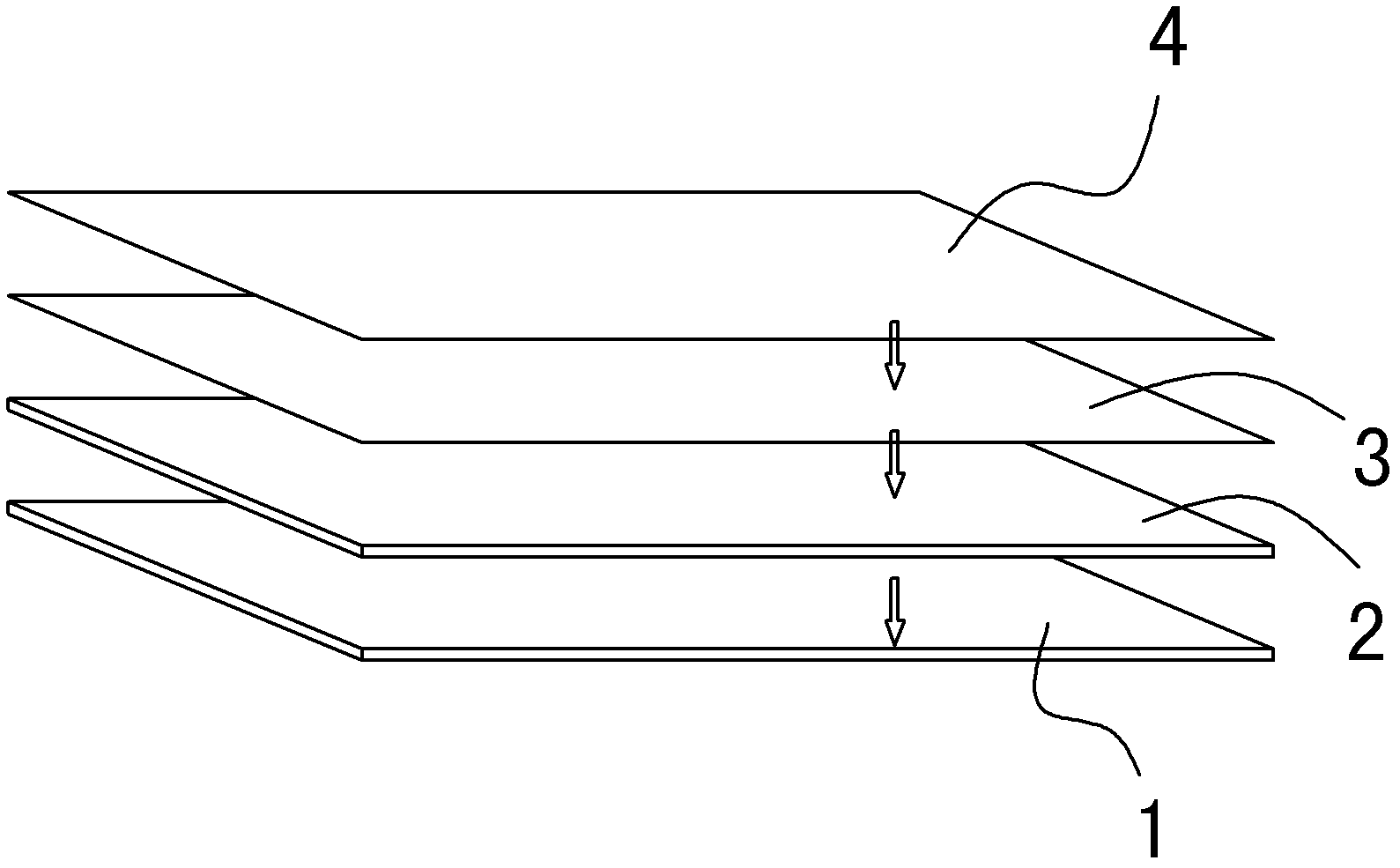

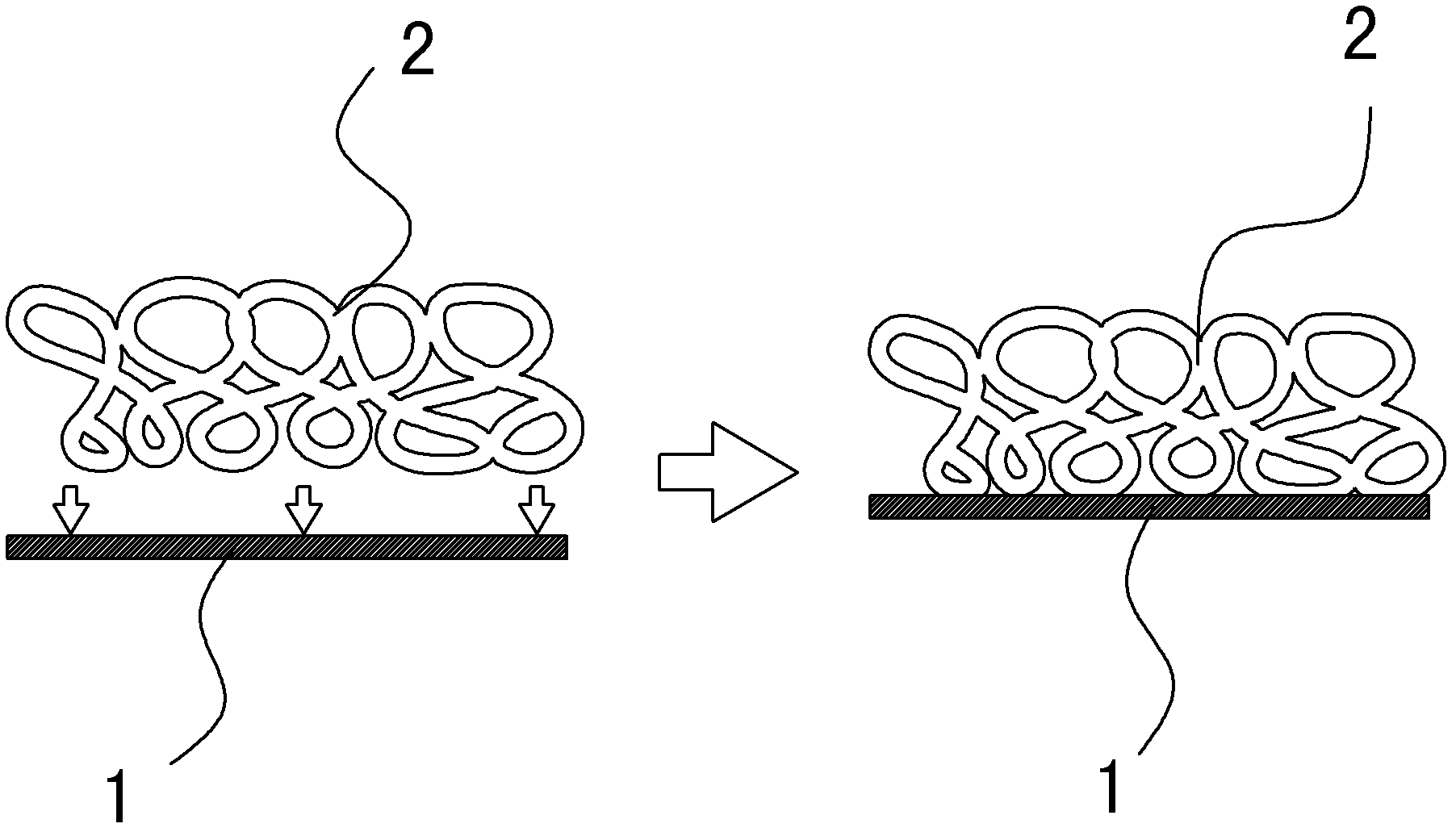

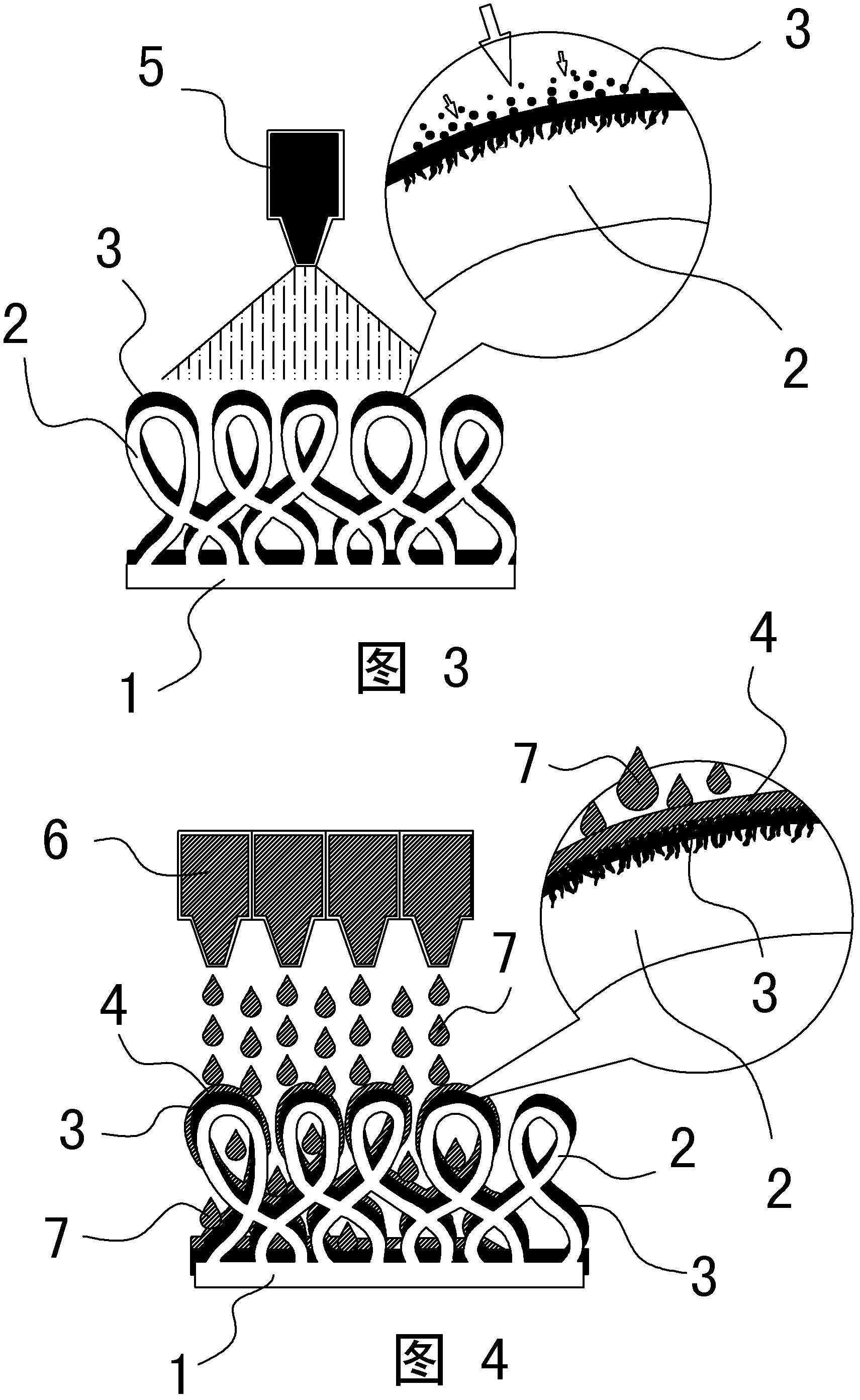

[0055] The pattern color spraying method of the plastic wire loop floor mat of the present invention is made up of following two parts:

[0056] Part 1 Color selection of plastic wire loop floor mats

[0057] Select white or light-colored plastic silk circle floor mats as the color spraying object, wherein, the white color is colorless; The standard shade concentration ratio of a primary color is based on 100%, which meets one of the following two colors:

[0058] The first color is any one of the four primary colors, and the density ratio of dark and light is less than or equal to 30% of the reference;

[0059] The second color is a mixed color of at least two primary colors among the four primary colors, and the sum of the density ratios of the various primary colors is less than or equal to 30% of the reference.

[0060] The second part: pattern color spraying process of plastic wire loop floor mat

[0061] For white or light-colored plastic wire loop floor mats, follow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com