Method for synthesizing flaky sodium niobate powder with large length-diameter ratio

A large aspect ratio, sodium niobate technology, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of uneven distribution, restricting the texture degree of piezoelectric ceramics, process instability, etc. Simple, low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

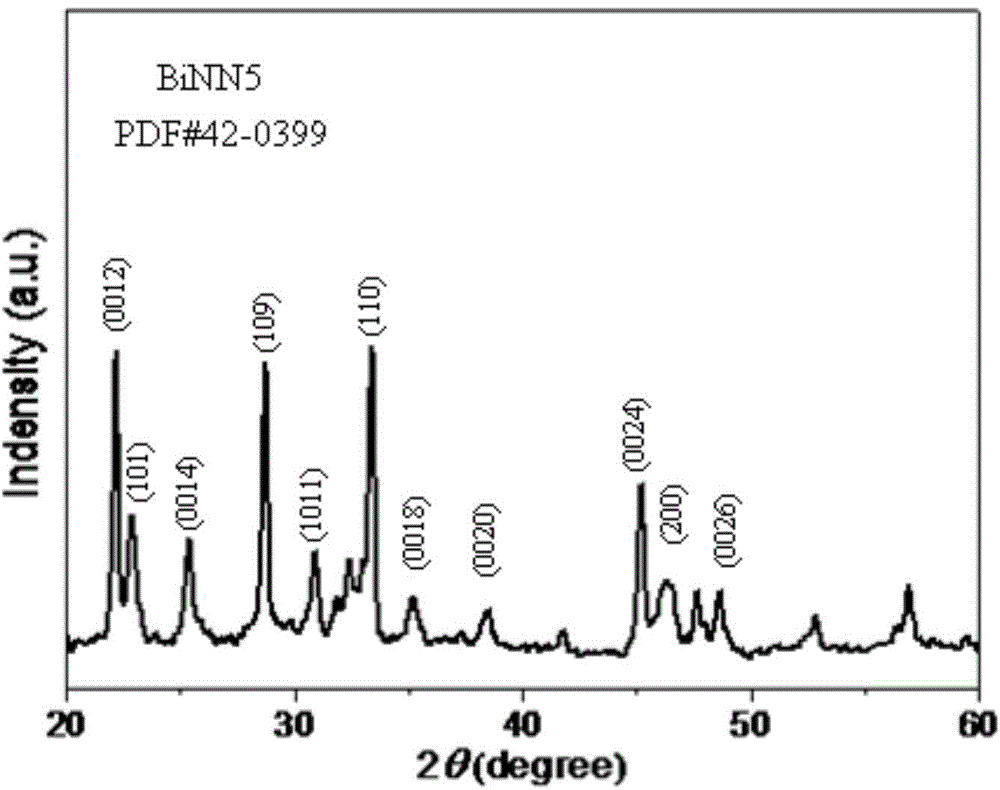

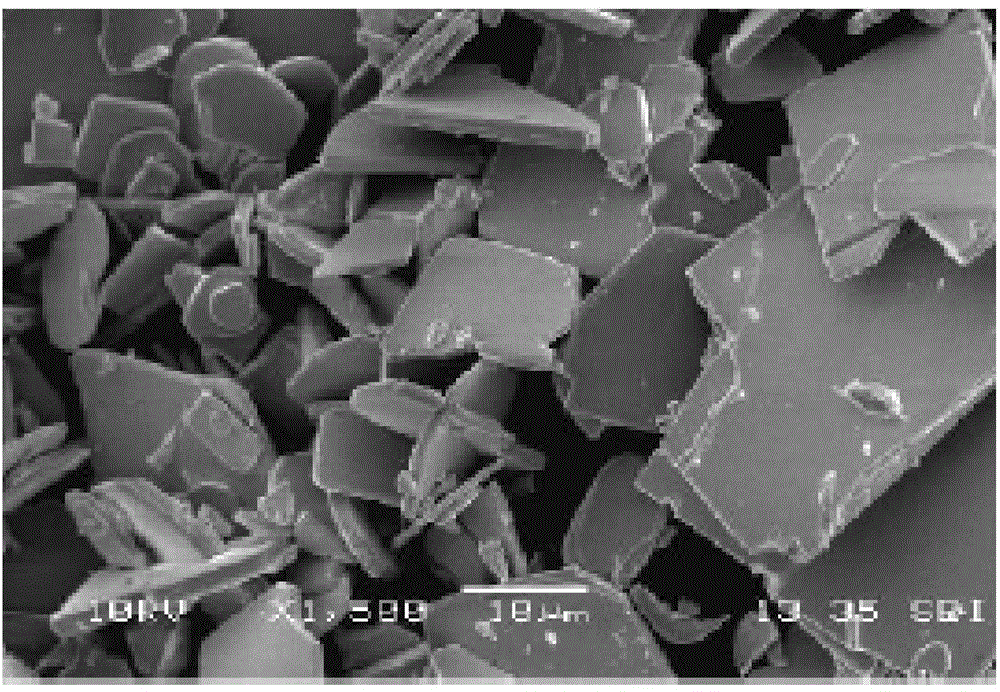

[0034] Take Na 2 CO 3 Preparation of sheet-loaded Bi for raw materials 2.5 Na 3.5 Nb 5 o 18 Powder: weigh 6.524gBi 2 o 3 , 1.484gNa 2 CO 3 and 5.317gNb 2 o 5 , then weighed 14.658g NaCl powder, mixed all the powder with absolute ethanol ball mill for 24 hours, dried the mixed material, put it into an alumina crucible and put it in a furnace to keep warm for 1 hour at 805°C and heat up (the heating rate is 2°C / min) to the synthesis temperature of 1100°C for 2 hours, then cooled to room temperature with the furnace, put it into the Buchner funnel to wash away NaCl, and dried to obtain flake Bi 2.5 Na 3.5 Nb 5 o 18 Powder, figure 1 is based on Na 2 CO 3 Flake Bi prepared as raw material 2.5 Na 3.5 Nb 5 o 18 The SEM image of the powder, by figure 1 It can be seen that the prepared Bi 2.5 Na 3.5 Nb 5 o 18 The particle size range of the powder is 5μm-20μm, the thickness is 2μm, the size is uneven, and there are many fragments.

Embodiment 2

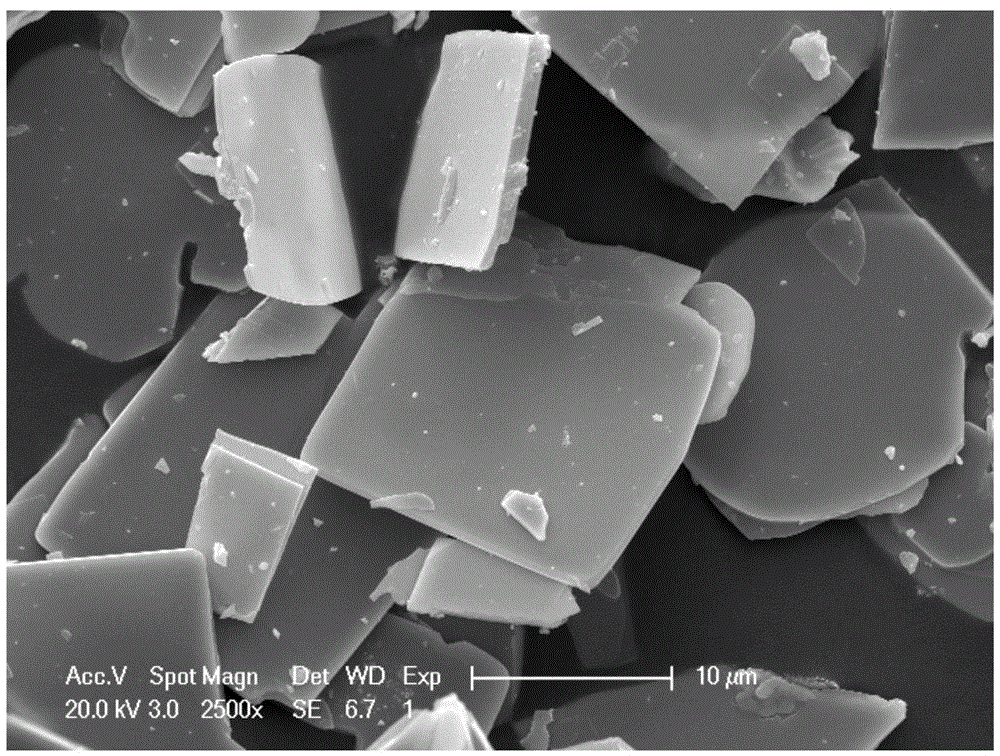

[0036] with K 2 CO 3 Preparation of sheet-loaded Bi for raw materials 2.5 Na 3.5 Nb 5 o 18 Powder: weigh 6.524gBi 2 o 3 , 1.935gK 2 CO 3 and 5.317gNb 2 o 5 , then weighed 15.153g of NaCl powder, mixed all the powder with absolute ethanol ball mill for 24 hours, dried the mixed material, put it into an alumina crucible and put it in a furnace to keep warm for 1 hour at 805°C and heat up (the heating rate is 2°C / min) to the synthesis temperature of 1000°C for 2 hours, then cooled to room temperature with the furnace, put it into a Buchner funnel to wash away NaCl, and dried to obtain flake Bi 2.5 Na 3.5 Nb 5 o 18 Powder, figure 2 is based on K 2 CO 3 Flake Bi prepared as raw material 2.5 Na 3.5 Nb 5 o 18 The SEM image of the powder, by figure 2 It can be seen that the prepared Bi 2.5 Na 3.5 Nb 5 o 18 The particle size range of the powder is 15μm-30μm, and the thickness is 1μm. From this it can be clearly seen that by K 2 CO 3 Na 2 CO 3 Made of raw...

Embodiment 3

[0038] Take Na 2 CO 3 with flake Bi 2.5 Na 3.5 Nb 5 o 18 The powder is used as the raw material, and NaCl is selected as the molten salt. According to the above chemical reaction formula (2), the flaky NaNbO can be prepared 3 Powder. The specific steps are as follows: Weigh 0.541gNa 2 CO 3 , 3.6gBi 2.5 Na 3.5 Nb 5 o 18 and 4.555g of NaCl powder, the powder is mixed, with absolute ethanol as the rolling medium, wherein the quality of zirconia balls is; rolling for 10 hours, after the discharge is dried, put it into an alumina crucible, and pre-burn it at 805 ° C for 1 After 1 hour, raise the temperature to 1000°C and keep it warm for 2 hours, then cool to room temperature with the furnace. Soak the prepared powder with boiling deionized water for one day, and constantly replace the deionized water, and clean it with ultrasonic waves until the AgNO 3 Solution test solution free of Cl after washing - (removal of NaCl). Then the cleaned product is repeatedly washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com