Film attachment method of light guide plate

A light guide plate and film material technology, which is applied in chemical instruments and methods, light guides, optics, etc., can solve problems affecting the manufacturing process, incomplete pasting, and pasting deviations, and achieve uniform distribution of the force-bearing area, simple film material numbers, and The effect of streamlining inventory management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

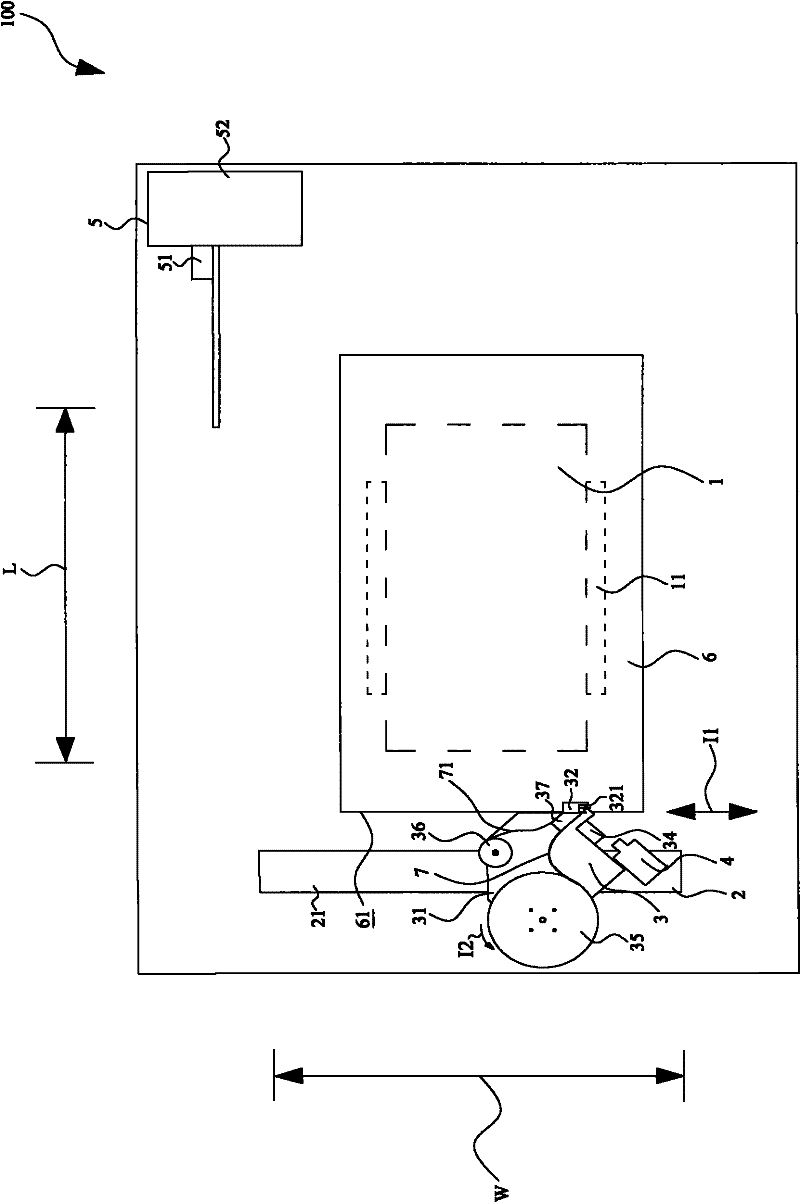

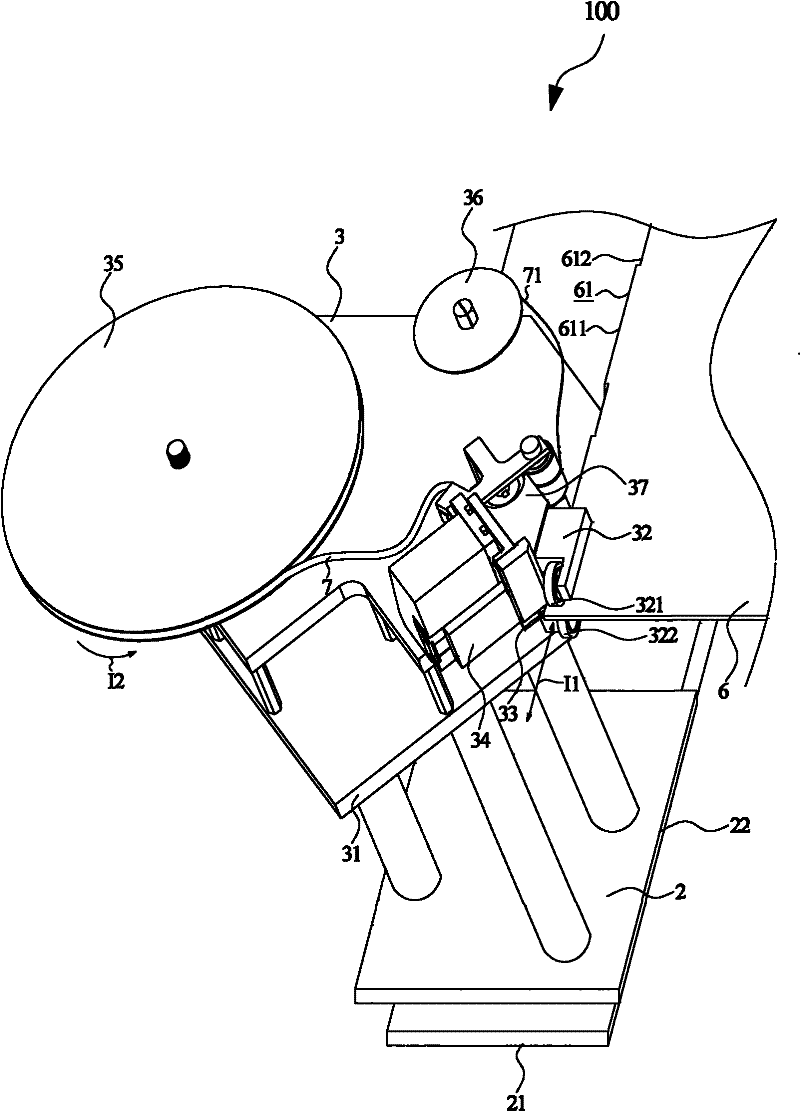

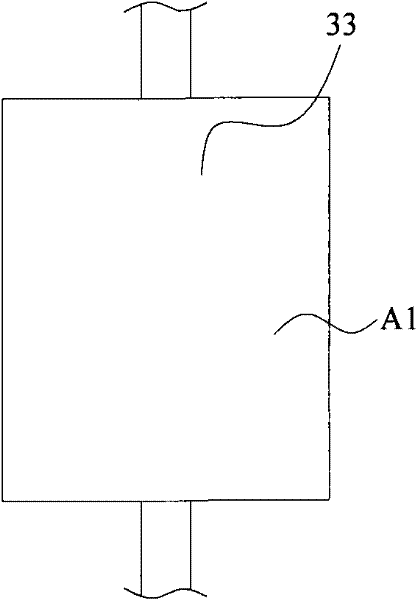

[0039] see also Figure 1 to Figure 4 shown, figure 1 It is the top view of the film material attaching device of the film material attaching method of the light guide plate according to the embodiment of the present invention, figure 2 It is a schematic diagram of the actual operation of the film material attaching mechanism of the film material attaching method of the light guide plate according to the embodiment of the present invention, 3A to 3D It is a schematic diagram of the narrow surface and the narrow line of the attachment member according to the embodiment of the present invention, Figure 4 It is a flow chart of an embodiment of a method for attaching a film material to a light guide plate of the present invention.

[0040] In the present invention, the film attaching device 100 for implementing the film attaching method includes a holding mechanism 1 , a sliding mechanism 2 , a film attaching mechanism 3 , a positioning sensing device 4 and an attaching devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com