Preparation method of nano cellulose with antibacterial property

A technology of nanocellulose and antibacterial properties, applied in the field of polymer material preparation, can solve the problems of low yield of nanocellulose preparation, poor dispersion of organic solvents, and restrictions on large-scale production, and achieve excellent antibacterial ability and biocompatibility Good performance, solve the effect of cumbersome preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

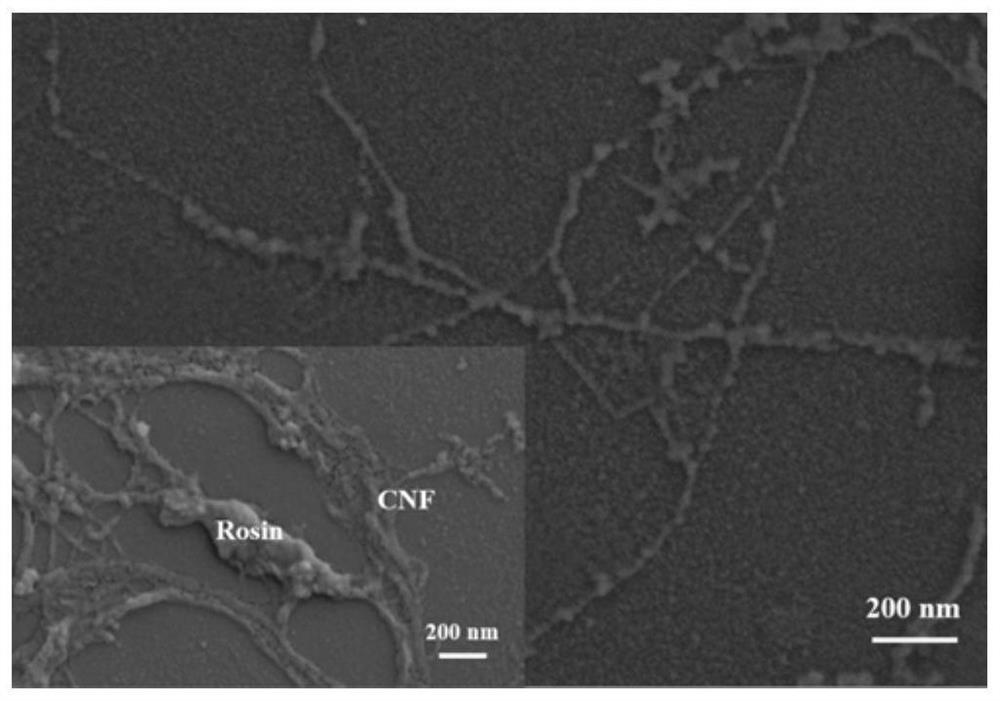

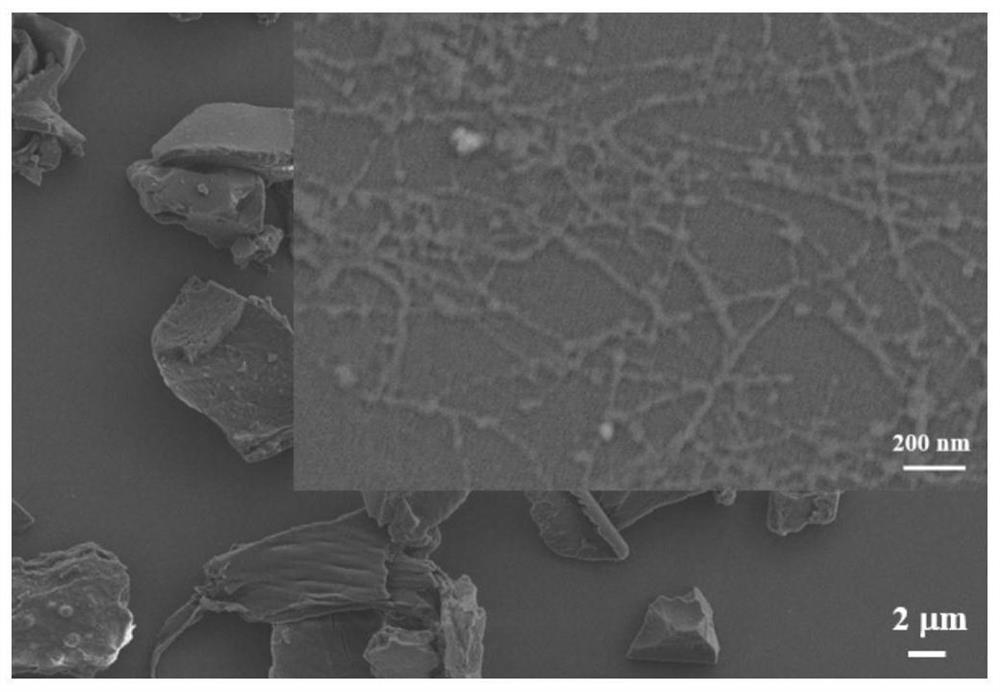

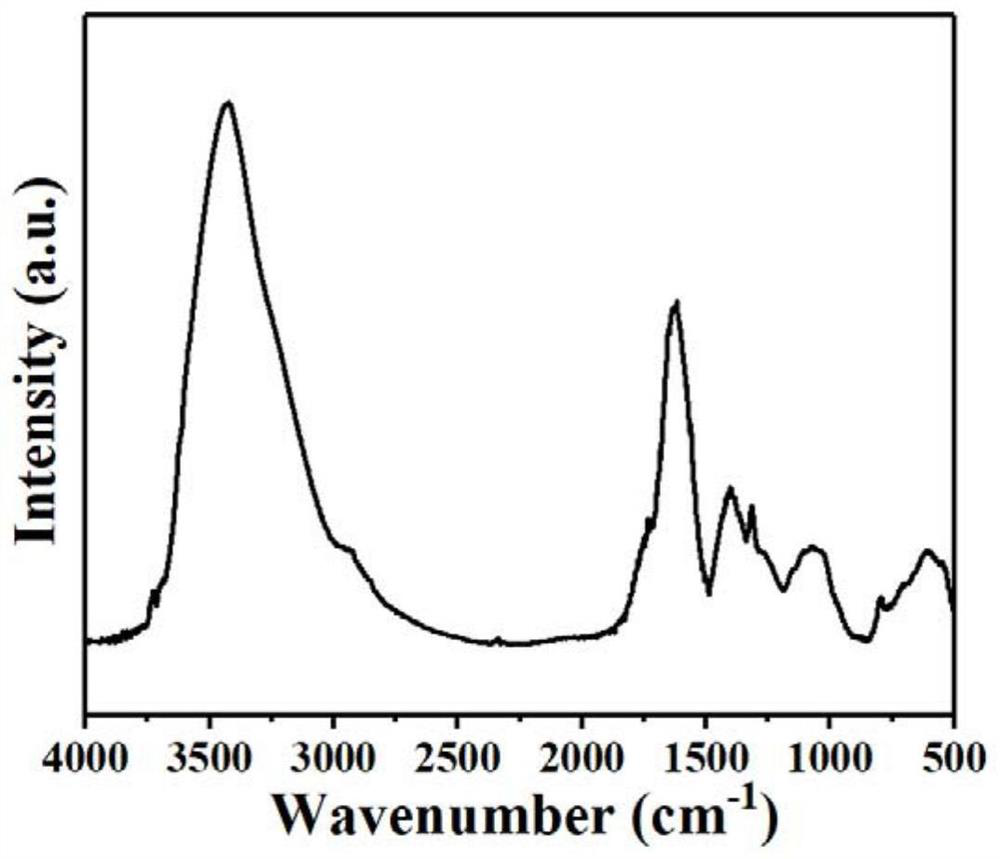

[0031] Put the pine cone in an oven at 60°C for 6 h, after grinding, add 30% hydrogen peroxide solution to the ground pine cone powder at a solid-to-liquid ratio of 1:150, seal it and put it away The beaker containing pine cone powder and hydrogen peroxide solution was placed in a water bath at 60°C, heated and stirred for 6 h, then placed in an ultrasonic cleaner at 10°C, and ultrasonicated for 30 min to obtain nanocellulose.

Embodiment 2

[0033] Dry the pine needles in an oven at 50°C for 5 h. After grinding, add 10% hydrogen peroxide solution to the ground pine needle powder with a solid-to-liquid ratio of 1:50, seal it and put it in a container. The beaker of pine needle powder and hydrogen peroxide solution was placed in a water bath at 80 °C, heated and stirred for 5 h, and then placed in an ultrasonic cleaner at 5 °C for 35 min to obtain nanocellulose.

Embodiment 3

[0035] Dry the pine bark in an oven at 80°C for 10 h. After grinding, add 15% hydrogen peroxide solution to the ground pine bark powder with a solid-to-liquid ratio of 1:100, seal it and put it away. Place the beaker with pine bark powder and hydrogen peroxide solution in a water bath at 70°C, heat and stir for 7 hours, then place the beaker in an ultrasonic cleaner at 0°C for 40 minutes to obtain nanocellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com