Radial and defection combined loading bench test tool for traction bar

A combined loading and bench test technology, applied in the direction of measuring devices, vehicle testing, mechanical component testing, etc., can solve problems such as damage to the bench actuator, actuator damage, difficult deflection force, etc., to ensure the test. The effect of accuracy, low manufacturing cost, safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

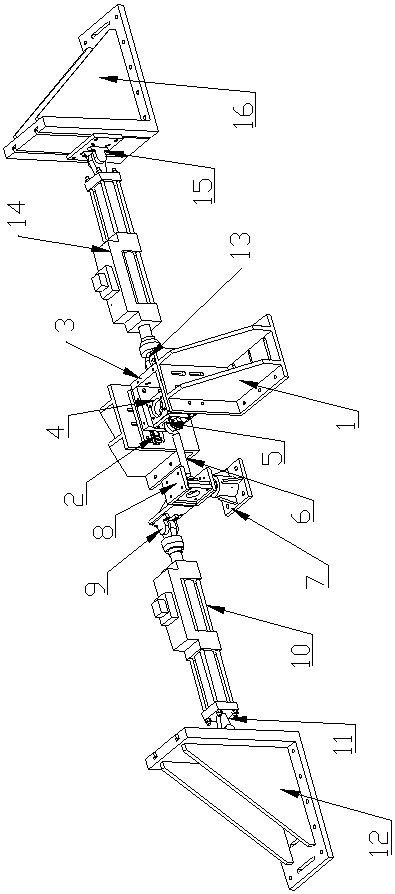

[0015] Such as figure 1 As shown, a thrust rod radial plus deflection combined loading bench test tooling, it includes a slide rail reaction force support 1, the rear side of the slide rail reaction force support 1 is connected with a linear slide rail 2, the described The linear slide rail 2 is connected with a fixed frame 3, and the inside of the fixed frame 3 is connected with a fixed block 4, and the left side of the fixed block 4 is connected with a ball hinge connecting block 5, and the ball hinge connecting block 5 is hinged with a thrust rod 6, the other end of the thrust rod 6 is hinged with a rotating base 7, the upper part of the rotating base 7 is connected with a deflection tool 8, and the left side of the deflection tool 8 is connected with a deflection Actuator ball joint B9, the deflection actuator ball joint B9 is hinged with a deflection actuator 10, the left end of the deflection actuator 10 is hinged with a deflection actuator ball hinge A11, and the deflec...

Embodiment 2

[0018] Such as figure 1 As shown, a thrust rod radial plus deflection combined loading bench test tooling, it includes a slide rail reaction force support 1, the rear side of the slide rail reaction force support 1 is connected with a linear slide rail 2, the described The linear slide rail 2 is connected with a fixed frame 3, and the inside of the fixed frame 3 is connected with a fixed block 4, and the left side of the fixed block 4 is connected with a ball hinge connecting block 5, and the ball hinge connecting block 5 is hinged with a thrust rod 6, the other end of the thrust rod 6 is hinged with a rotating base 7, the upper part of the rotating base 7 is connected with a deflection tool 8, and the left side of the deflection tool 8 is connected with a deflection Actuator ball joint B9, the deflection actuator ball joint B9 is hinged with a deflection actuator 10, the left end of the deflection actuator 10 is hinged with a deflection actuator ball hinge A11, and the deflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com