A preparation method of manganese oxide@ni-co/graphite carbon nanometer microwave absorbing composite material

A nano-composite material and manganese oxide technology, applied in antennas, electrical components, etc., can solve the problems of narrow absorption frequency band and weak magnetic loss, so as to reduce the use of KCl, improve electromagnetic wave absorption performance, and enhance dielectric loss capability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

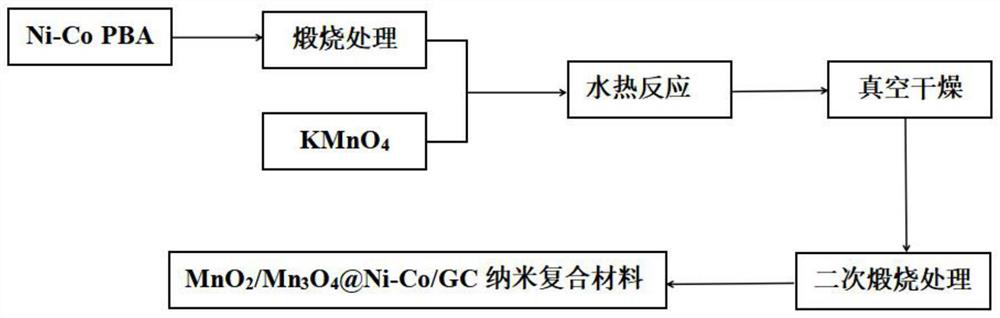

[0034] A preparation method of manganese oxide @Ni-Co / graphite carbon nanometer microwave absorbing composite material, comprising the following specific steps:

[0035] (1) Preparation of Ni-Co / Graphite Carbon Material

[0036] Disperse 529.38 mg of sodium citrate and 348.95 mg of nickel nitrate hexahydrate in 40 mL of deionized water and fully dissolve to obtain solution A, then disperse 258.67 mg of potassium cobaltcyanide (Ⅲ) in 40 mL of deionized water to obtain solution B;

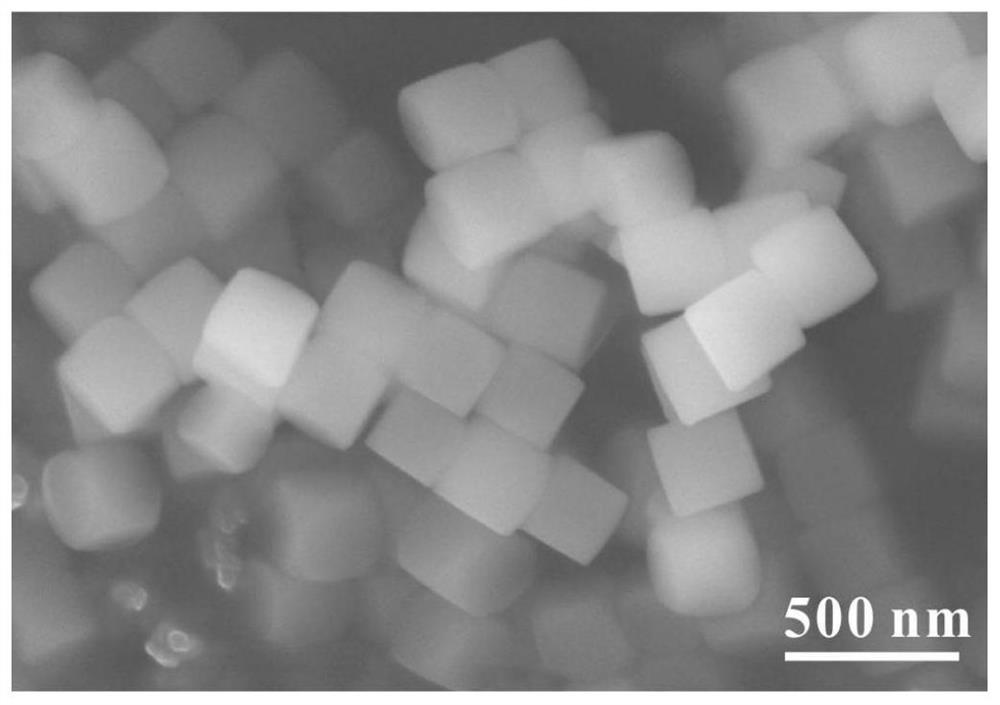

[0037] The two were quickly mixed and stirred continuously, aged at 25 °C for 24 h, the precipitate was filtered, washed with deionized water and absolute ethanol, and dried in vacuum for 12 h to obtain Ni-Co PBA crystals;

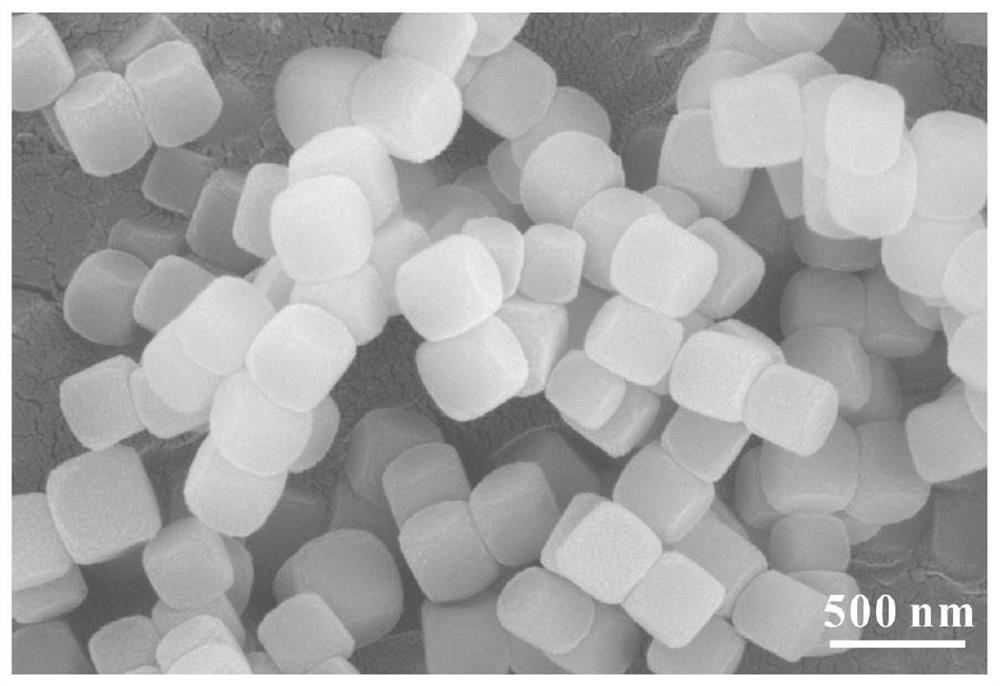

[0038] Put 100 mg of Ni-Co PBA crystal into a porcelain boat, and place it in a tube furnace for annealing treatment. The annealing treatment step is to raise the temperature to 350 °C at a heating rate of 2 °C / min in an argon atmosphere, and maintain 1.5 h, After naturally cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com