CoFe@ C/rGO electromagnetic wave absorption composite material and preparation method thereof

A technology for absorbing composite materials and composite materials, which is applied in the field of CoFe@C/rGO electromagnetic wave absorbing composite materials and its preparation, can solve the problems of sheet aggregation, single attenuation loss mechanism, poor impedance matching characteristics, etc. Dielectric loss capability and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

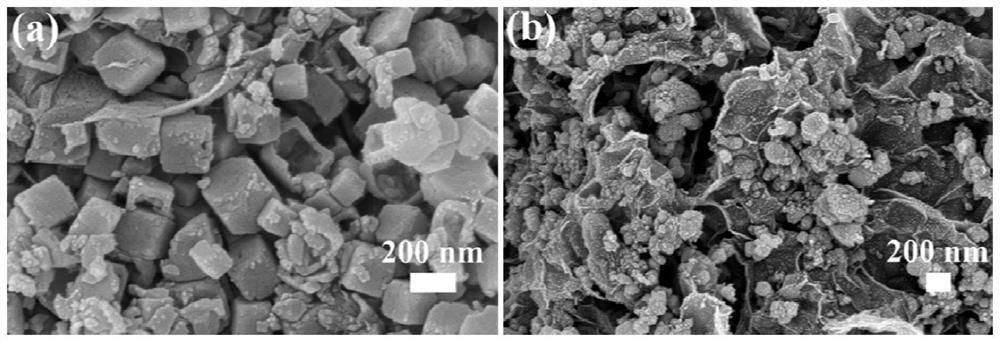

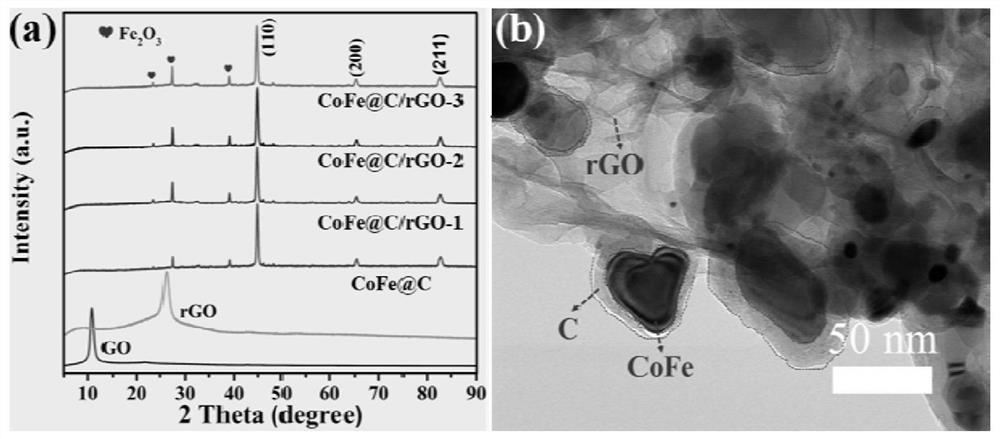

[0029] Example 1: Preparation of CoFe@C composite material

[0030] (1) Add 0.294g of sodium citrate dihydrate and 0.3g of cobalt acetate tetrahydrate into 80mL of deionized water, ultrasonically treat for 2 hours, and dissolve completely to obtain solution A. Add 0.264g of potassium ferricyanide into 120mL of deionized water, completely Dissolving to obtain solution B;

[0031] (2) Magnetically stir solution A, then pour solution B into solution E within 1 minute, and continue stirring for 10 minutes to obtain solution C, then put solution C in a water bath at 90°C for 8 hours, and then centrifuge and wash for final Obtain CoFe Prussian blue analogue;

[0032] (3) The CoFe Prussian blue analogue was annealed at 600°C under an argon atmosphere, the annealing time was 2h, and the annealing rate was 2°C / min to obtain 0.18g of CoFe@C composite material.

Embodiment 2

[0033] Example 2: Preparation of CoFe@C / rGO-1 composite material

[0034] (1) Add 0.035g of graphene oxide (GO) into 80mL of deionized water, and ultrasonically treat it for 1h to completely dissolve it in deionized water to obtain solution A;

[0035] (2) Add 0.294 g of sodium citrate dihydrate and 0.3 g of cobalt acetate tetrahydrate into solution A, completely dissolve to obtain solution B, add 0.264 g of potassium ferricyanide into 120 mL of deionized water, and completely dissolve to obtain solution C;

[0036] (3) Magnetically stir solution B, then pour solution C into solution B within 1 min, and continue to stir for 10 min to obtain solution D, then put solution D in a water bath at 90°C for 8 h, and finally undergo centrifugal washing treatment. Obtain CoFe Prussian blue analogue / GO composite material;

[0037] (4) The CoFe Prussian blue analogue / GO composite material was annealed at 600 °C under an argon atmosphere for 2 h, and the annealing rate was 2 °C / min to obt...

Embodiment 3

[0038] Example 3: Preparation of CoFe@C / rGO-2 composite material

[0039] (1) Add 0.05g of graphene oxide (GO) into 80mL of deionized water, and ultrasonically treat it for 0.5h to completely dissolve it in deionized water to obtain solution A;

[0040] (2) Add 0.294 g of sodium citrate dihydrate and 0.3 g of cobalt acetate tetrahydrate into solution A, completely dissolve to obtain solution B, add 0.264 g of potassium ferricyanide into 120 mL of deionized water, and completely dissolve to obtain solution C;

[0041] (3) Magnetically stir solution B, then pour solution C into solution B within 20 seconds, and continue to stir for 5 minutes to obtain solution D, then put solution D in a water bath at 80°C for 6 hours, and finally undergo centrifugal washing treatment. Obtain CoFe Prussian blue analogue / GO composite material;

[0042] (4) The CoFe Prussian blue analogue / GO composite material was annealed at 600 °C under an argon atmosphere for 2 h, and the annealing rate was 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com