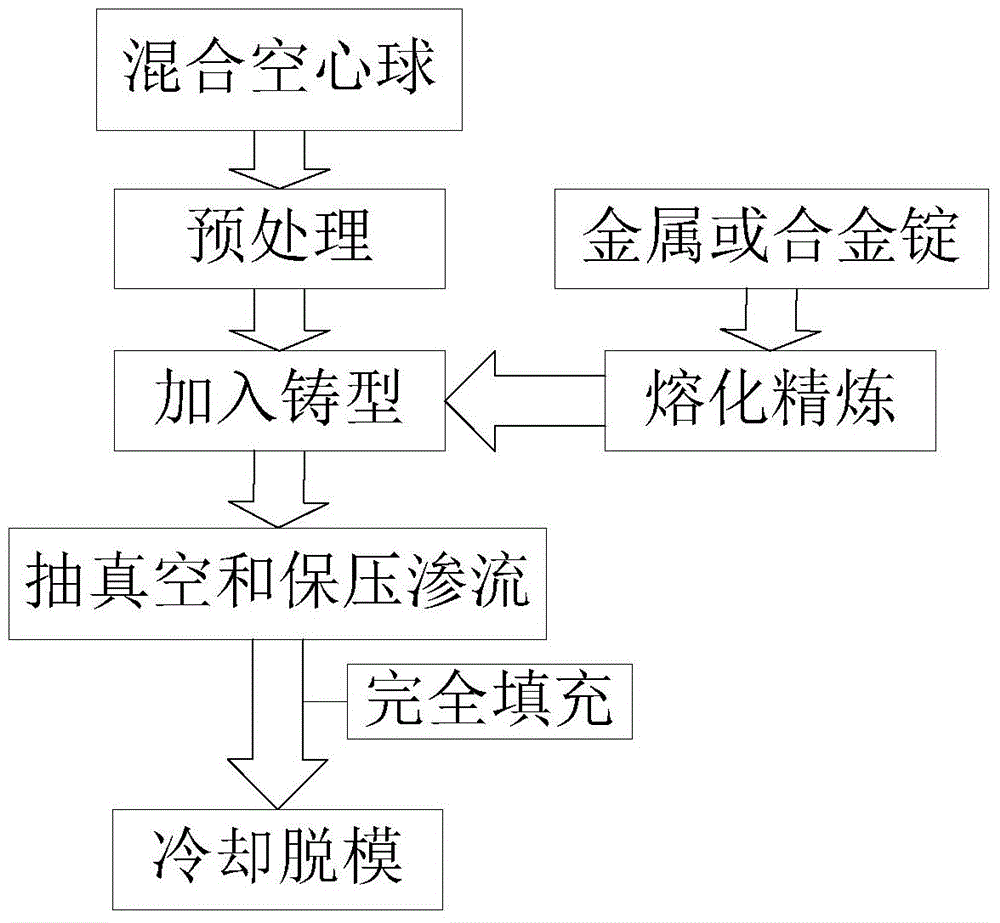

One-stage method for preparing metal matrix light-weighted composite material

A composite material and metal-based technology, which is applied in the field of preparing metal-based lightweight composite materials, can solve the problems of complex preparation process, high density and high cost, and achieve the effects of simple process flow, reduced density and fewer steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In this embodiment, aluminum alloy is selected as the base metal, and SiC hollow spheres and Al mixed in any proportion are selected. 2 O 3 Hollow sphere 5, the diameter of the hollow sphere is 0.5mm-5mm, SiC hollow sphere and Al 2 O 3 The hollow sphere has high melting point and high hardness, and can be fully mixed with aluminum alloy without significantly reducing the compressive properties of the alloy material.

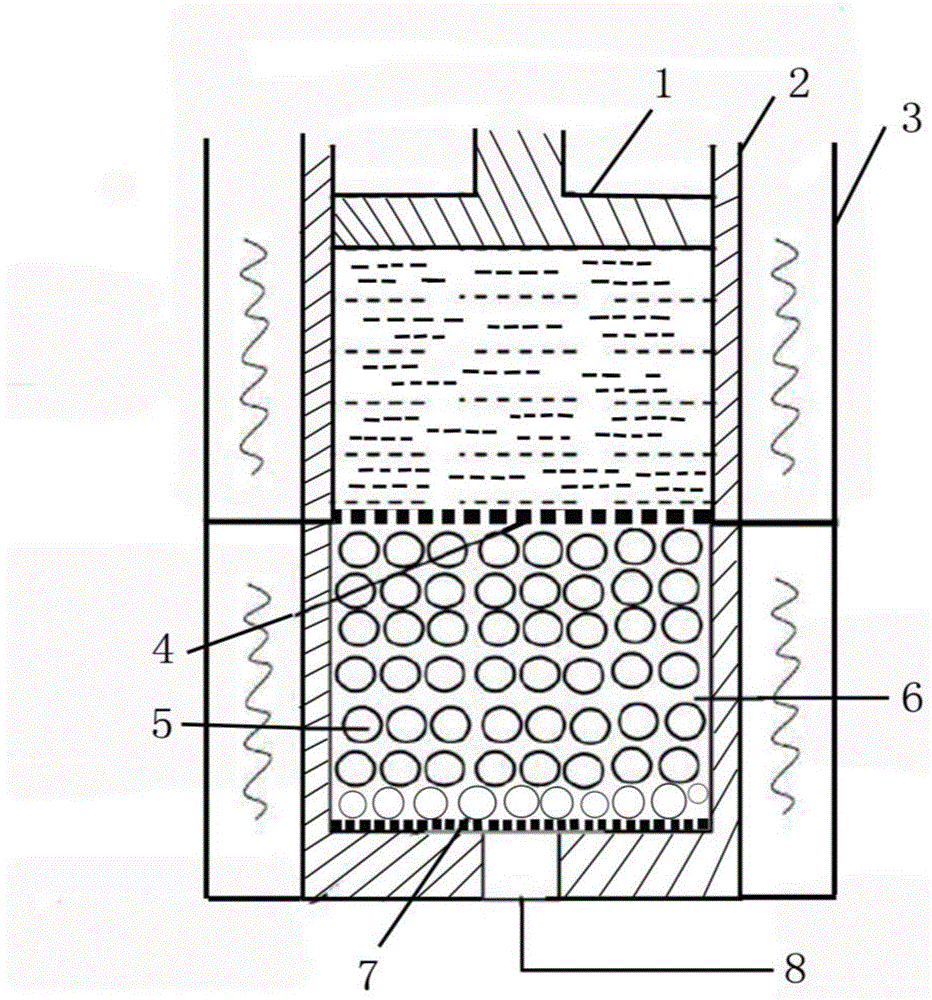

[0024] The mould used in the preparation method (see figure 2 ) consists of a pressure holding mold 1, a crucible 2, a resistance heating furnace 3, a macroporous porous ceramic or graphite plate 4, a vacuum chamber 6, a small porous ceramic or graphite plate 7 and a vacuum system 8. The preparation steps are: (1) pickling hollow spheres with a diameter of 0.5-5mm or heat treatment at 300-800 DEG C for 2-5h; (2) padding a commercially available 0.2mm-thick 10mm hole at the bottom of the casting mold The small-pore porous ceramic or graphite 7, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com