Low temperature condition preparation of orientated growth nanometer flaky Bi2Fe4O9

A technology of bi2fe4o9 and nano flakes, which is applied in the field of preparation of directional growth nano flakes Bi2Fe4O9 by hydrothermal method, can solve the problem of harsh experimental environment, no material crystal structure preferred growth, solid state reaction uniformity and controllability can not be matched Compared with hydrothermal reaction and other problems, it achieves the effect of good feasibility and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

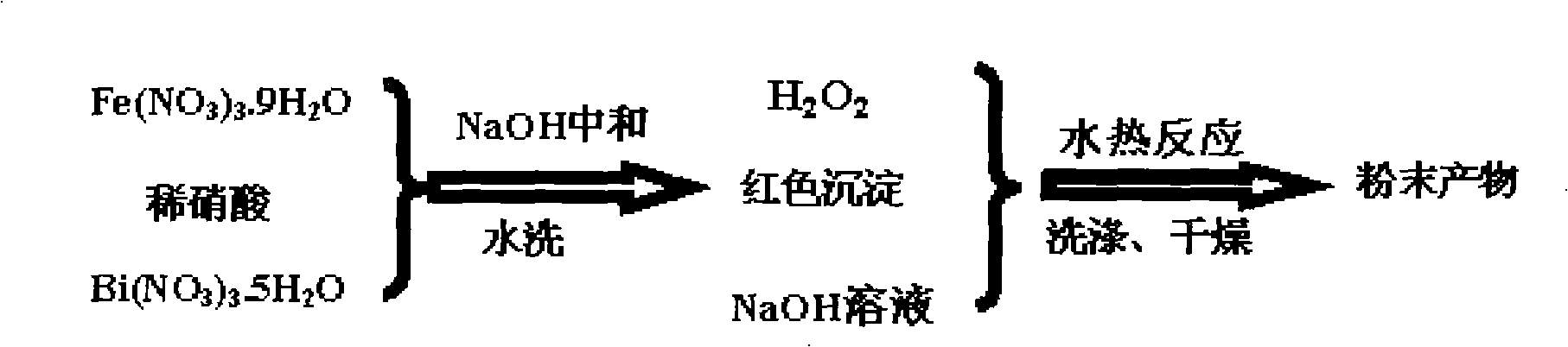

Embodiment 1

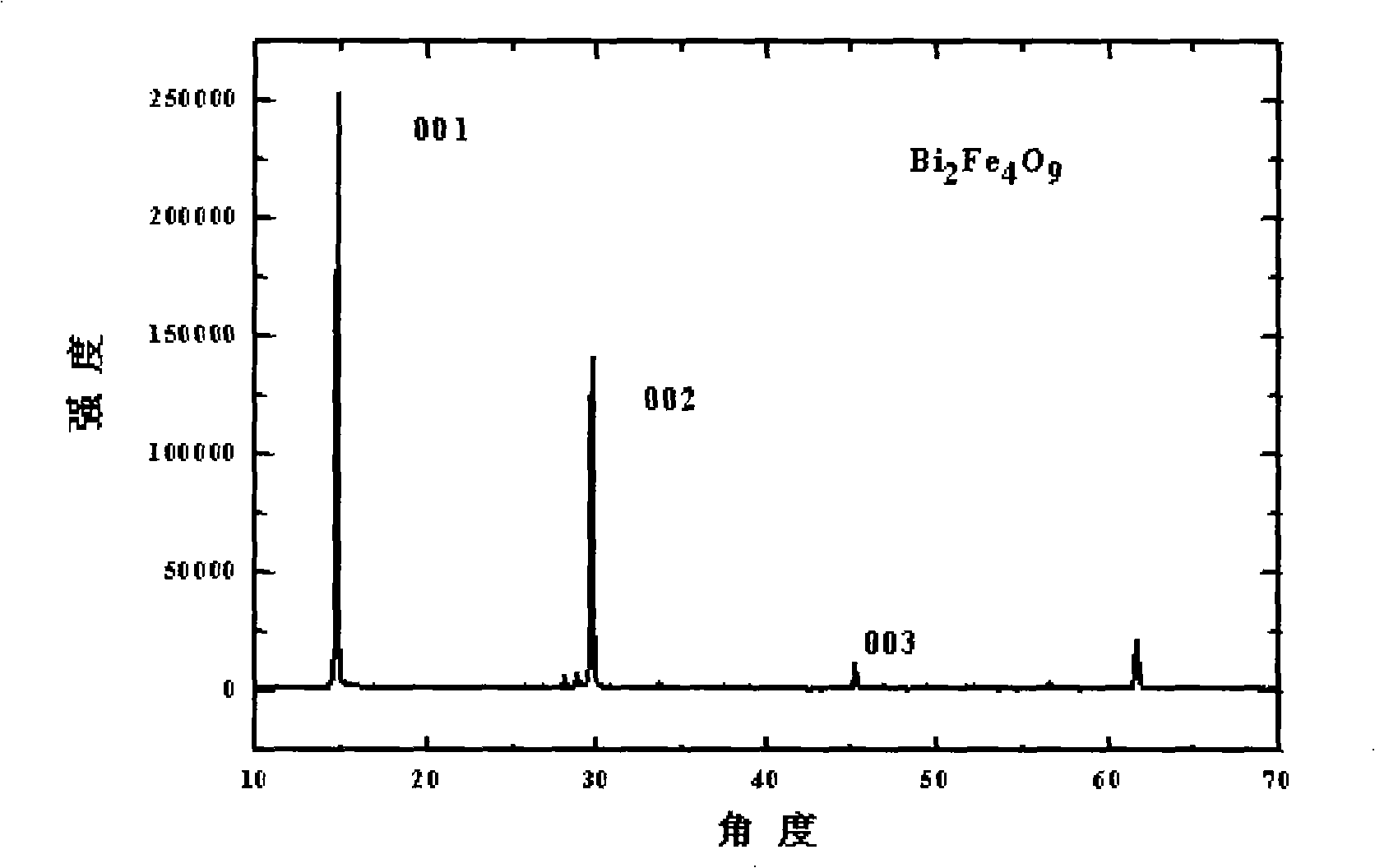

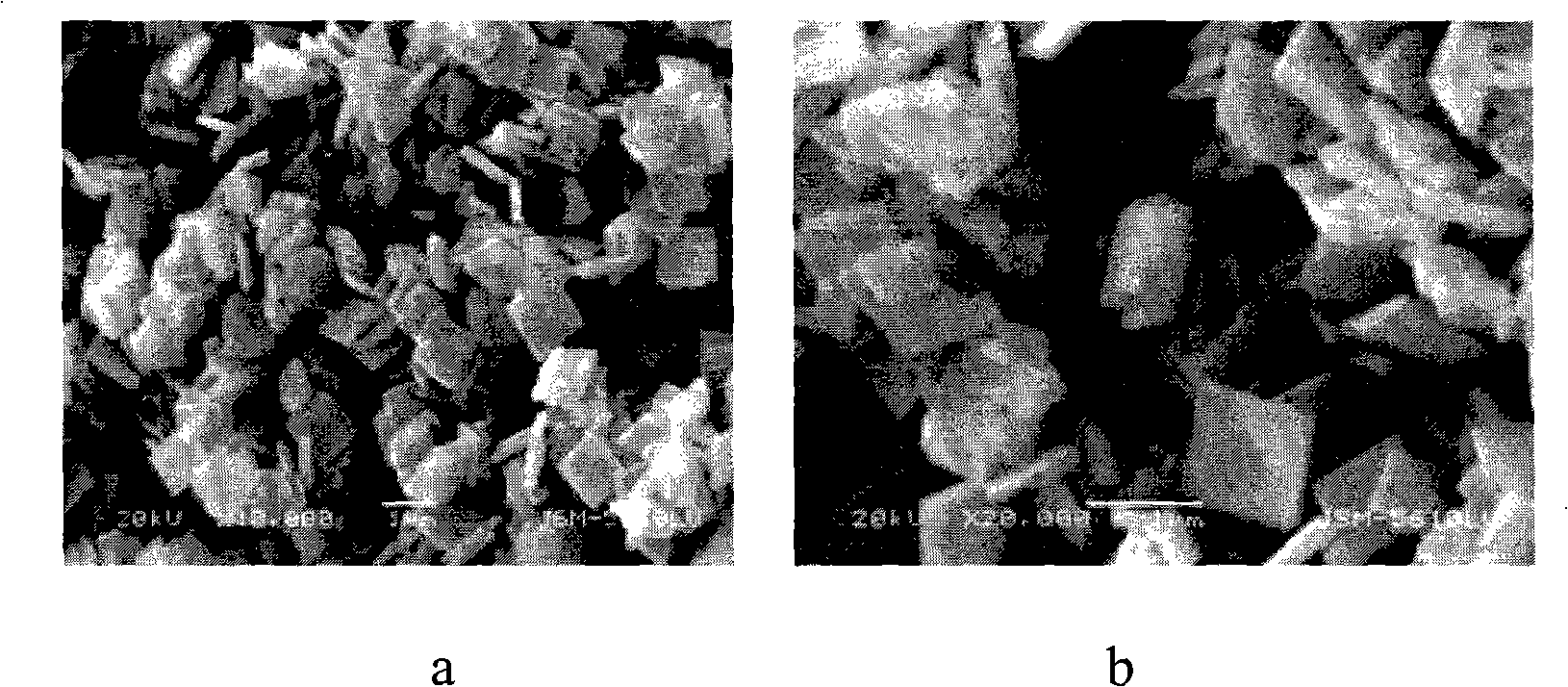

[0035] Bi(NO 3 ) 3 ·5H 2 O 1.94 g (4 mmol) and Fe(NO 3 ) 3 9H 2 O 1.616 grams (4 millimoles) are dissolved in the dilute nitric acid of 0.1 equivalent concentration, then titrate with the NaOH aqueous solution of 12 mol / liter to precipitation completely, wash with suction filtration water until the solution is neutral, also wash away wherein Na + and NO 3 - . The obtained precipitate was dissolved in a NaOH aqueous solution with a concentration of 8 mol / liter to form a 40 ml solution, wherein Bi(NO 3 ) 3 ·5H 2 The concentration of O is 100 mmol / L, Fe(NO 3 ) 3 9H 2 The concentration of O is 100 mmol / L, add 2 mL of H 2 o 2 , quickly poured into a 50 ml reaction kettle, put it in a 160°C oven for 72 hours, took it out, washed it twice with deionized water and once with alcohol, put it in a 60°C oven for 4 hours, and the final product was highly directional growth Nanosheet Bi 2 Fe 4 o 9 .

Embodiment 2

[0037] Bi(NO 3 ) 3 ·5H 2 O 970 mg (2 mmol) and Fe (NO 3 ) 3 9H 2 O 808 milligrams (2 millimoles) are dissolved in the dilute nitric acid of 0.1 equivalent concentration, then titrate with 12 mol / L NaOH aqueous solution until the precipitation is complete, wash with suction filtration until the solution is neutral, and also wash off the Na therein + and NO 3 - . The obtained precipitate was dissolved in an aqueous NaOH solution with a concentration of 20 mol / liter to form a 40 ml solution, wherein Bi(NO 3 ) 3 ·5H 2 The concentration of O is 50 mmol / L, Fe(NO 3 ) 3 9H 2 The concentration of O is 50 mmol / L, add 2 mL of H 2 o 2 , quickly poured into a 50 ml reaction kettle, put it in a 200°C oven for 50 hours, took it out, washed it twice with deionized water and once with alcohol, put it in a 100°C oven for 2 hours, and the final product was highly directional growth Nanosheet Bi 2 Fe 4 o 9 .

Embodiment 3

[0039] Bi(NO 3 ) 3 ·5H 2 O 232.8 mg (0.48 mmol) and Fe (NO 3 ) 3 9H 2 O 193.9 mg (0.48 mmol) was dissolved in dilute nitric acid of 0.1 normal concentration, then titrated with 12 mol / liter of NaOH aqueous solution until the precipitation was complete, and washed with suction and filtered water until the solution was neutral, and the Na therein was also washed away + and NO 3 - . The precipitate obtained is dissolved in a NaOH aqueous solution with a concentration of 12 mol / liter to form a 40 ml solution, wherein Bi(NO 3 ) 3 ·5H 2 The concentration of O is 12 mmol / L, Fe(NO 3 ) 3 9H 2 The concentration of O is 12 mmol / L, add 2 mL of H 2 o 2 , quickly poured into a 50 ml reaction kettle, put it in an oven at 180°C for 50 hours, took it out, washed it twice with deionized water and once with alcohol, put it in an oven at 80°C for 4 hours, and the final product was highly directional growth Nanosheet Bi 2 Fe 4 o 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com