High-toughness sintered flux for submerged-arc welding, and preparation method thereof

A technology of sintering flux and submerged arc welding, which is applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of insufficient slag removal effect, and achieve the effect of excellent welding process performance, excellent comprehensive mechanical properties, and beautiful weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below through the description of specific embodiment, but this is not limitation to the present invention, those skilled in the art can make various modification or modification according to the basic idea of the present invention, as long as not departing from the basic idea of the present invention , are within the scope of the present invention.

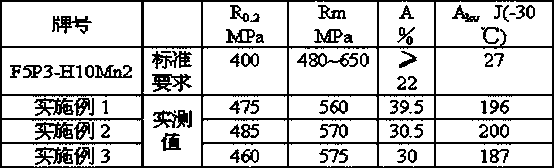

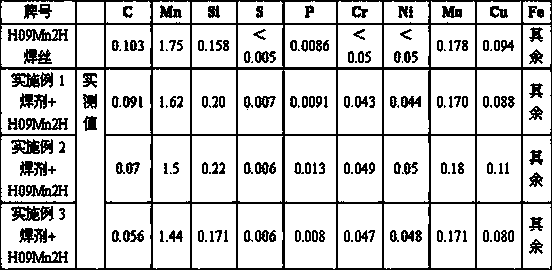

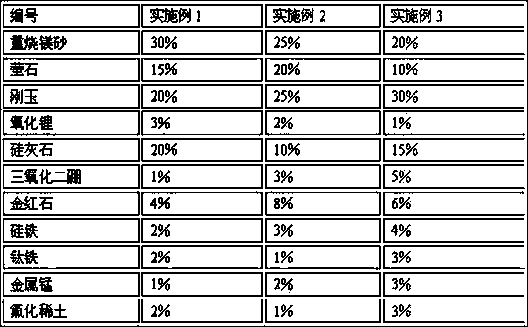

[0021] Table 1 is a list of weight percentage ratios of dry flux powder components in Examples 1 to 3.

[0022] Table 1 Example dry powder composition weight percentage ratio

[0023]

[0024] Mix the dry flux powders of Example 1~Example 3 in Table 1 and mix evenly in proportion, then add potassium water glass with M=2.6, 40~43 Be at 20°C as a binder to granulate, and then granulate at 200°C Low-temperature drying for 1 hour, high-temperature sintering at 780°C for 40 minutes, then air-cooled, passing through a 20-60-mesh sieve, packaging, and making finished flux.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com