Growing method and growing device for indium phosphide single crystal

A growth method and indium phosphide technology, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of reducing the dislocation density of the indium phosphide single crystal, high risk, and large amount of red phosphorus, etc. The effect of long service life, reduced risk and simplified equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

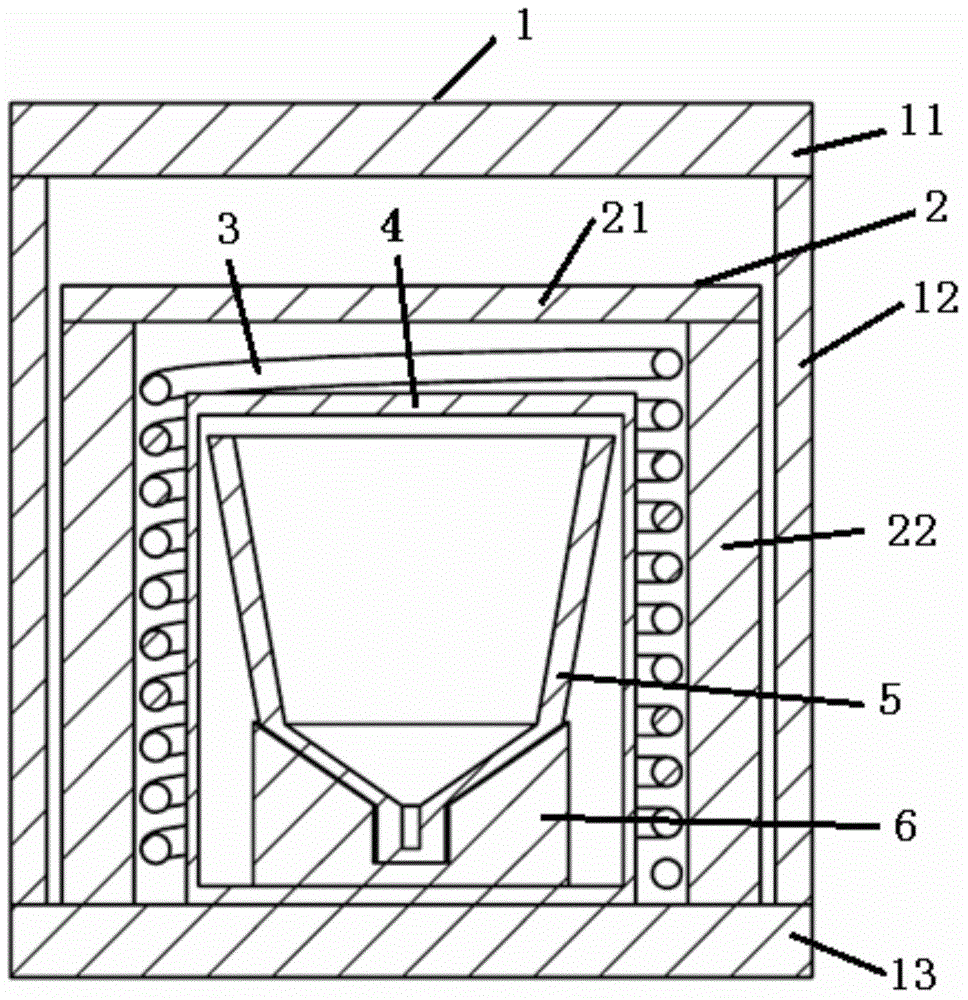

[0070] use figure 1 In the growth device shown, the size of the pressure-resistant chamber 1 is 200mm in inner diameter; the insulation chamber 2 is a mullite insulation cotton insulation chamber with an inner diameter of 150mm and a thickness of 20mm; the insulation chamber cover 21 has a thickness of 20mm; the heater 3 has a rated power of 10kW The first crucible 4 is a quartz crucible with an inner diameter of 100 mm and a thickness of 5 mm; the second crucible 5 is a PBN crucible (pyrolytic boron nitride crucible) with an inner diameter (the diameter of the crucible after the crucible shoulders are finished) of 80 mm and a thickness of 5 mm. 5mm; the base 6 is a quartz base, which fits closely with the bottom of the second crucible 5 .

[0071] Place the quartz base 6 at the center of the bottom of the quartz crucible 4 , and place the pBN crucible 5 on the quartz base 6 . Make the dislocation density less than 2000cm -2 The direction indium phosphide single crystal see...

Embodiment 2

[0075] use figure 1 In the growth device shown, the pressure chamber 1 has an inner diameter of 250mm; the heat preservation chamber 2 is a mullite insulation cotton heat preservation chamber with an inner diameter of 200mm and a thickness of 20mm; the heat preservation chamber cover 21 has a thickness of 20mm; the heater 3 has a rated power of 15kW The first crucible 4 is a quartz crucible with an inner diameter of 150 mm and a thickness of 5 mm; the second crucible 5 is a PBN crucible (pyrolytic boron nitride crucible), and an inner diameter (the diameter of the crucible after the crucible puts the shoulders) is 110 mm. The thickness is 5mm; the base 6 is a quartz base, which closely fits with the bottom of the second crucible 5 .

[0076] Place the quartz base 6 at the center of the bottom of the quartz crucible 4 , and place the pBN crucible 5 on the quartz base 6 . Make the dislocation density less than 2000cm -2 The indium phosphide single crystal seed crystal in the ...

Embodiment 3

[0080] use figure 1 In the growth device shown, the pressure-resistant cavity 1 has an inner diameter of 300mm; the thermal insulation cavity 2 is a mullite thermal insulation cotton thermal insulation cavity with an inner diameter of 250mm and a thickness of 20mm; the thermal insulation cavity cover 21 has a thickness of 20mm; the heater 3 has a rated power of 20kW The first crucible 4 is a quartz crucible with an inner diameter of 200 mm and a thickness of 5 mm; the second crucible 5 is a PBN crucible (pyrolytic boron nitride crucible) with an inner diameter (the diameter of the crucible after the crucible shoulders are finished) of 160 mm and a thickness of 5 mm. 5mm; the base 6 is a quartz base, which fits closely with the bottom of the second crucible 5 .

[0081] Place the quartz base 6 at the center of the bottom of the quartz crucible 4 , and place the pBN crucible 5 on the quartz base 6 . Make the dislocation density less than 2000cm -2 The direction indium phosphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com