Uranium-bearing paigeite separating process

A technology, iron ore concentrate technology, applied in the field of uranium-containing boron iron ore sorting process, to achieve the effect of improving the sorting index and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with the attached table.

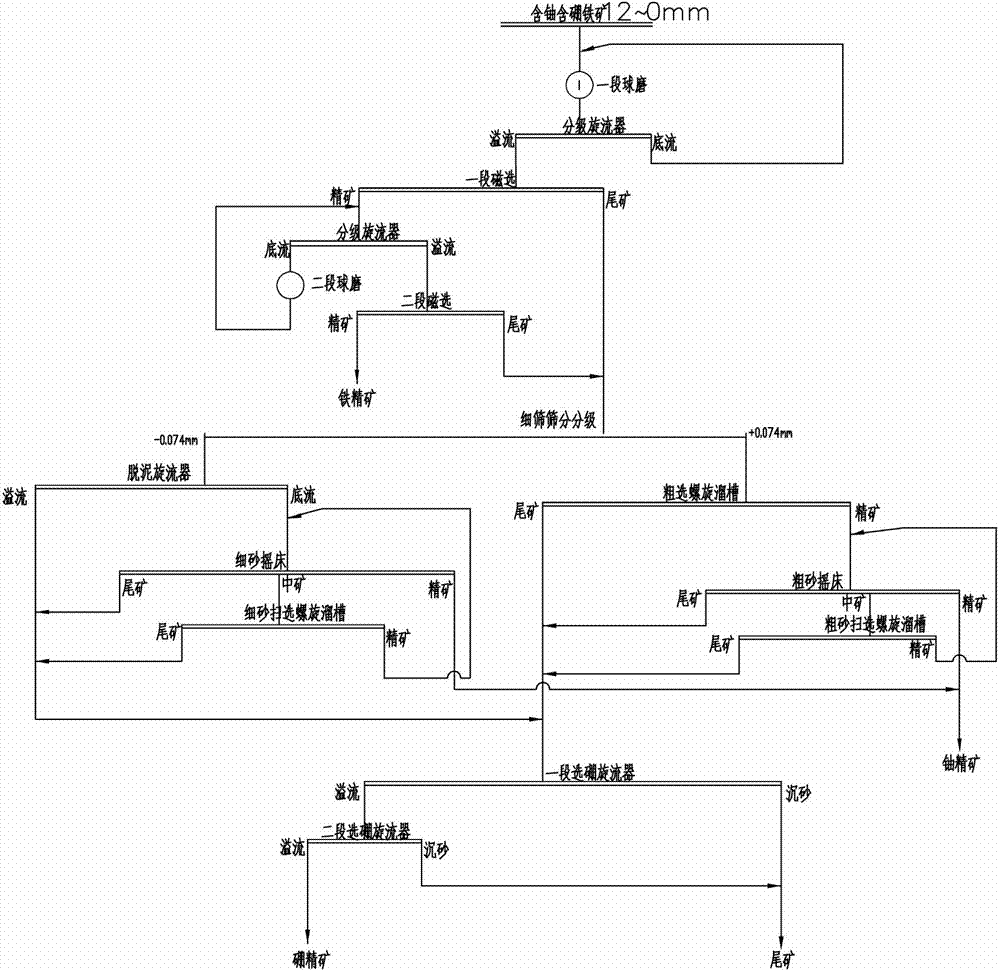

[0028] Such as figure 1 As shown, a kind of uranium-containing boron iron ore sorting process of the present invention is characterized in that comprising iron concentrate ore dressing process, uranium concentrate sorting process and boron concentrate sorting process,

[0029] a. Iron concentrate beneficiation process:

[0030] Two-stage grinding-classification-two-stage magnetic separation process is adopted, and the specific steps are as follows:

[0031] ⑴ After crushing and screening, the raw ore with a particle size of 0-12mm has an iron grade of 28%-32%, a uranium grade of 0.005%-0.006%, and a boron trioxide grade of 5%-7%. The belt conveyor is fed into the primary closed-circuit grinding composed of primary ball mill ~ cyclone I classification, and the proportion of ore powder of the primary closed-circuit grinding product is controlled at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com