Wet smashing device

A wet pulverizing and pulverizing cylinder technology, applied in the field of pulverizing equipment, can solve the problems of uneven particle size of materials, insignificant influence on extraction speed and effective ingredient yield, and difficulty in material screening, so as to achieve uniform particle size, improve effective ingredient yield, Improve the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

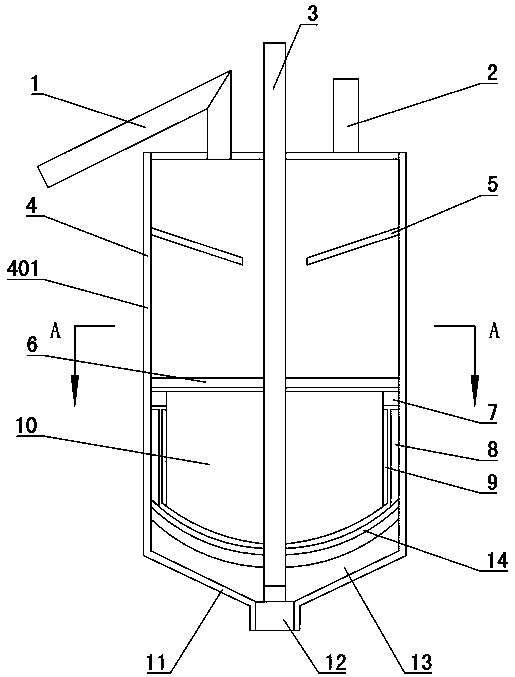

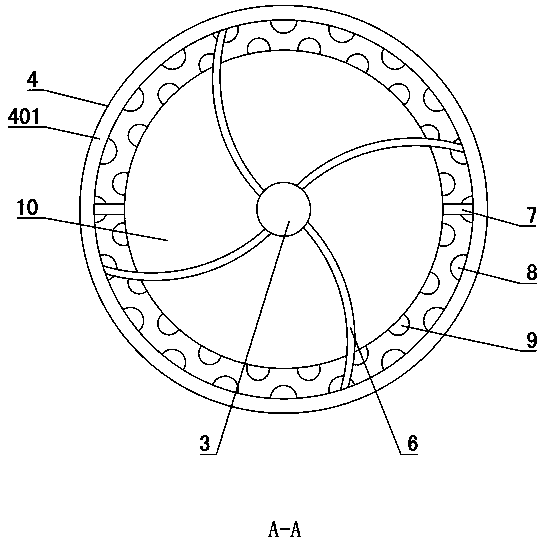

[0029] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~4 The present invention will be further described.

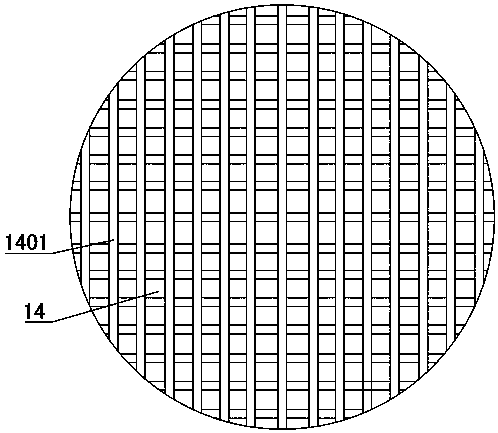

[0030] A kind of wet pulverizing device, comprises the pulverizing tube 4 that is arranged vertically and the pulverizing mechanism in pulverizing tube 4, and the lower end of pulverizing tube 4 is provided with the screening cover 14 that closes the lower end of pulverizing tube 4, and screening cover 14 is made of a plurality of The net cover spliced by rectangular blades 1401 is provided with a grinding part at the bottom of the crushing mechanism, and the grinding part is arranged on the upper side of the screening cover 14, and the grinding part and the screening cover 14 rotate relatively. The screening cover 14 of this wet crushing device can screen the crushed materials, and the materials that meet the particle size requirements pass through the screening cover 14 and are sent out. The grinding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com