Sealing glass material and preparation method thereof

A technology for sealing glass and glass liquid is applied in the field of sealing glass materials and their preparation, which can solve the problems of insufficient bonding strength, mismatched expansion coefficients, poor chemical stability, etc., and achieve improved chemical stability. , to ensure that the expansion coefficient is matched, and the effect of improving chemical stability and electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a sealing glass material, comprising the steps of:

[0029] 1), select chemical composition batching by following weight percentage:

[0030] SiO 2 :30%-50%, B 2 o 3 :30%-50%, Al 2 o 3 :3%-15%, Na 2 O: 3%-5%, K 2 O: 3%-5%, MgO: 0.01%-5%, CaO: 3%-10%, SrO: 0.01%-5%, BaO: 0.01%-5%, ZnO: 5%-10%, TiO 2 :0.01%-1%;

[0031] 2), the above-mentioned ingredients are placed in a planetary ball mill for ball milling, so that the ingredients are mixed evenly;

[0032] 3) Then put the ball-milled and mixed materials in the crucible, place the crucible in a high-temperature lifting furnace, heat it with the furnace until it is completely melted and clarified to obtain molten glass, pour the molten glass into cold distilled water, and quench it to obtain glass debris;

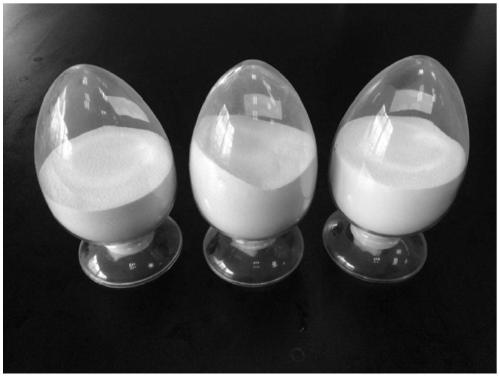

[0033] 4) Place the obtained glass cullet in an oven, bake at 75-100° C. for 12-24 hours, then grind the baked glass cullet, and pass through an 80-mesh sieve to obtain a sealing glass ...

Embodiment 1

[0046] A preparation method of sealing glass for primary lithium thionyl chloride battery terminals, specifically comprising the following steps:

[0047] 1), select chemical composition batching by following weight percentage:

[0048] Na 2 O is 3%, K 2 O is 3%, MgO is 0.95%, CaO is 5%, SrO is 5%, BaO is 3%, ZnO is 5%, TiO 2 0.05%, Al 2 o 3 5%, SiO 2 30%, B 2 o 3 40%.

[0049] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0050] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lifting furnace, and raise the temperature to 650°C at a rate of 10°C / min in an air atmosphere and keep it warm for 40min. Then increase the temperature at a rate of 10°C / min to 1500°C and keep it warm for 1.5 hours. During this period, stir several times to m...

Embodiment 2

[0070] A method for preparing a special sealing glass for primary lithium thionyl chloride battery terminals, specifically comprising the following steps:

[0071] 1), select chemical composition batching by following weight percentage:

[0072] Na 2 O is 4%, K 2 O is 4%, MgO is 2.5%, CaO is 5%, SrO is 5%, BaO is 5%, ZnO is 7%, TiO 2 0.5%, Al 2 o 3 7%, SiO 2 30%, B 2 o 3 30%;

[0073] 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0074] 3) Put the ball-milled and mixed materials in step (2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lifting furnace, and raise the temperature to 750°C at a rate of 10°C / min in an air atmosphere and keep it warm for 40min. Then increase the temperature at a rate of 10°C / min to 1400°C and keep it warm for 1.0 hour. During this period, stir several time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com