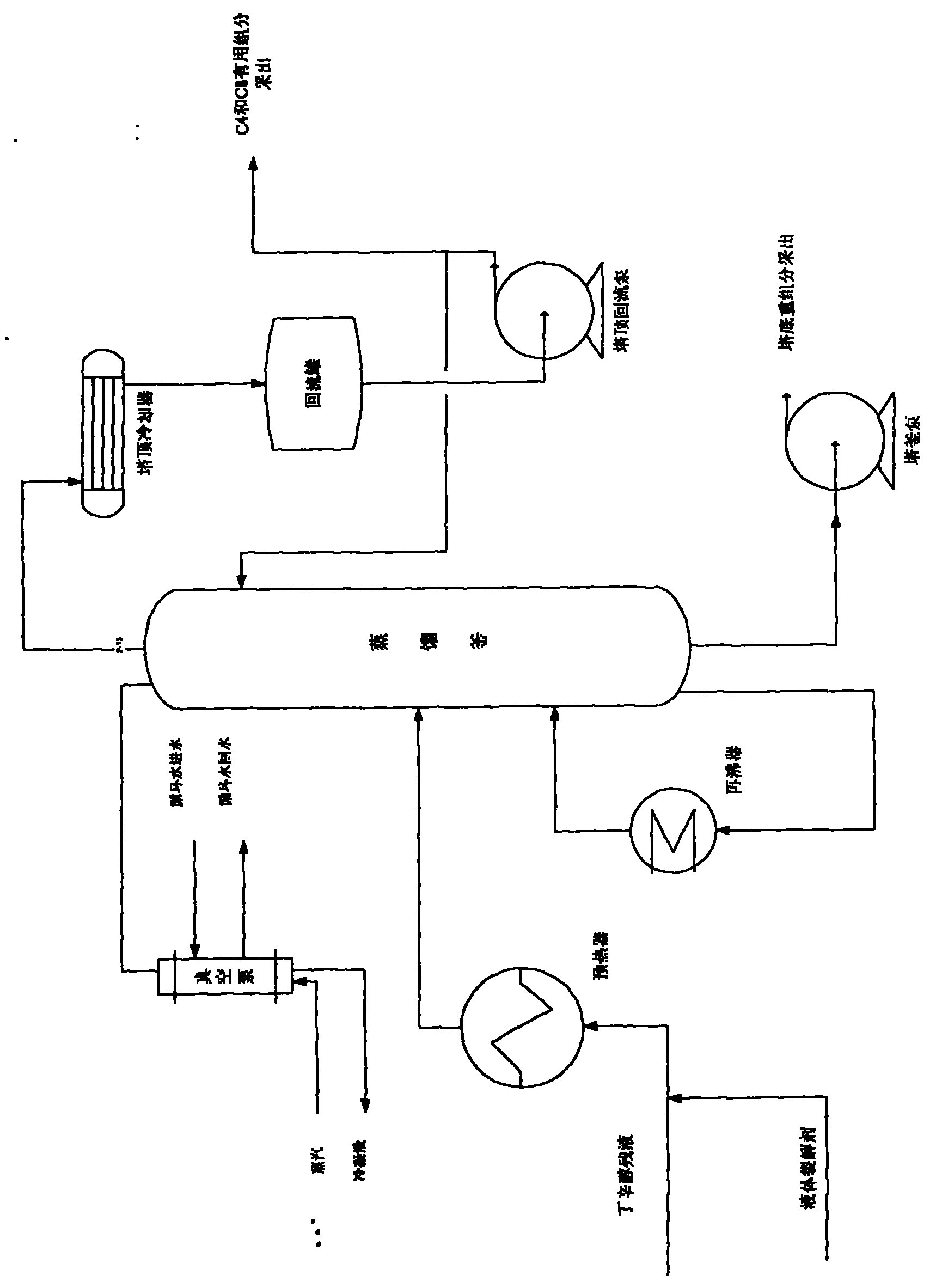

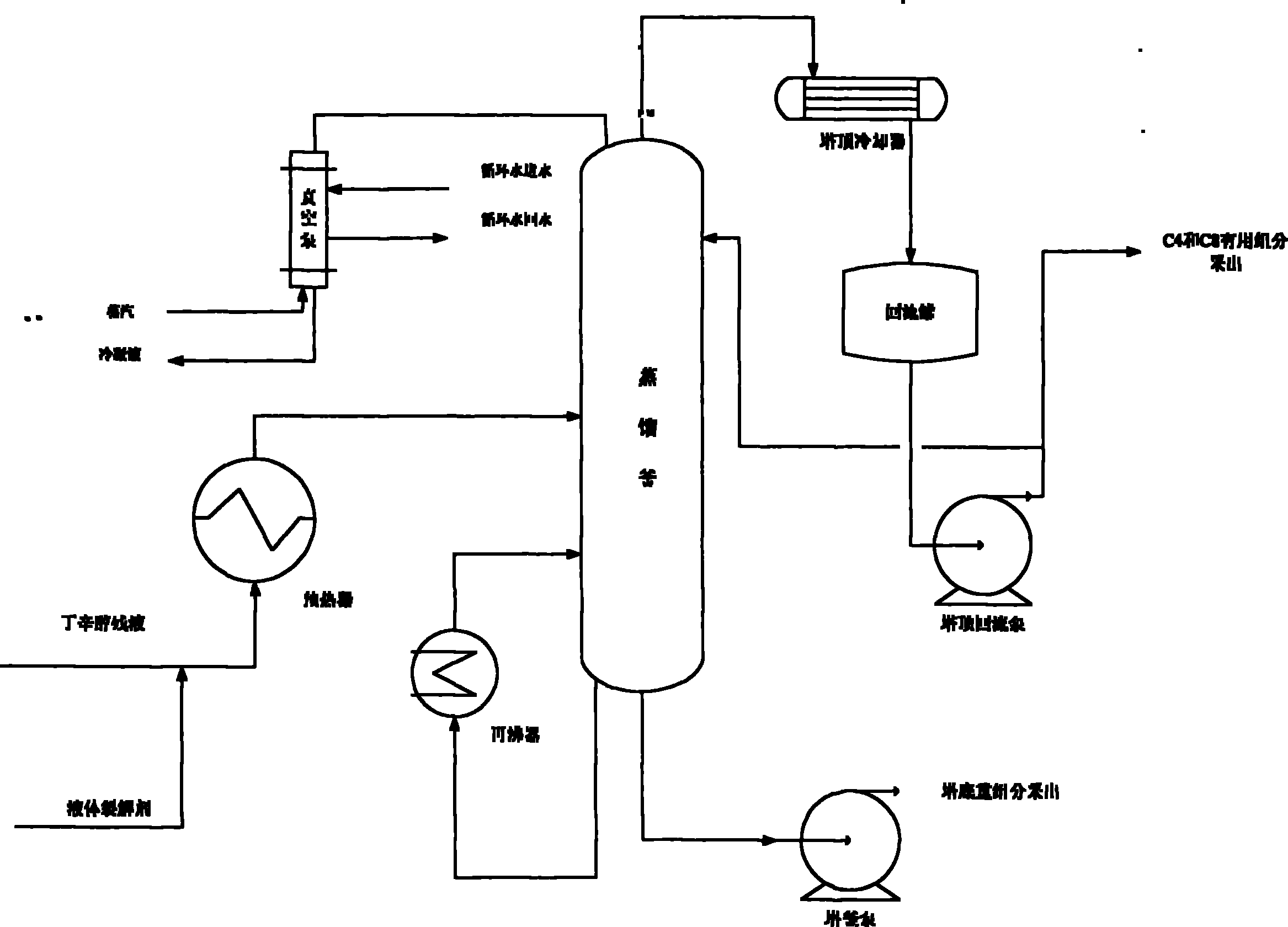

Production technology for cracking butyl octanol residual liquid into C4 and C8 by means of alkaline liquid cracking agent

A production process and cracking agent technology, applied in cracking, petroleum industry, non-catalytic thermal cracking, etc., can solve the problems of environmental damage, waste of resources, etc., and achieve the effects of environmental protection, emission reduction, and high content of useful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The quality composition of alkaline liquid cracking agent is: sodium hydroxide 15%, potassium hydroxide 30%, water 20%, isopropanol 12%, ethylene glycol 7%, potassium permanganate 6%, ethanol 8%, nitric acid Barium 1%, boron trioxide 1%.

[0016] The main composition of butanol raffinate: 0.7% for C4, 0.8% for C8, and 98.5% for heavy components (C12 and C16).

[0017] When the feed rate of butyl octanol raffinate accounted for 50% of still volume, the add-on of alkaline liquid cracking agent was 0.5% of raw material quality, 150 ℃ of preheater temperature, tower still temperature was 220 ℃, and tower top temperature was 150°C, the pressure at the top of the tower is -0.08Mpa. The components extracted at the top of the tower account for 80% of the mass of the butanol raffinate, the output of C4 accounts for 42% of the mass of the components extracted at the top of the tower, and the output of C8 accounts for 51% of the mass of the components extracted at the top of the ...

Embodiment 2

[0019] The mass composition of alkaline liquid cracking agent is: sodium hydroxide 5%, potassium hydroxide 10%, water 30%, isopropanol 15%, ethylene glycol 10%, potassium permanganate 10%, ethanol 10%, nitric acid Barium 5%, diboron trioxide 5%.

[0020] The main composition of butanol raffinate: C4 is 0.5%, C8 is 0.9%, and heavy components (C12 and C16) are 98.6%.

[0021] When the feed rate of butanol raffinate accounted for 60% of the still volume, the add-on of alkaline liquid cracking agent was 0.6% of the raw material amount, the preheater temperature was 180°C, the tower still temperature was 240°C, and the tower top temperature It is 170°C, and the pressure at the top of the tower is -0.09Mpa. The components extracted at the top of the tower account for 76% of the mass of the butanol raffinate, the output of C4 accounts for 41% of the mass of the components extracted at the top of the tower, and the output of C8 accounts for 53% of the mass of the components extracted...

Embodiment 3

[0023] The mass composition of alkaline liquid cracking agent is: sodium hydroxide 10%, potassium hydroxide 25%, water 25%, isopropanol 10%, ethylene glycol 8%, potassium permanganate 8%, ethanol 7%, nitric acid Barium 4%, boron trioxide 3%.

[0024] The main composition of butanol raffinate: 0.4% for C4, 0.8% for C8, and 98.8% for heavy components (C12 and C16).

[0025] When the feed rate of butanol raffinate accounted for 70% of the still volume, the add-on of alkaline liquid cracking agent was 0.7% of the raw material amount, the preheater temperature was 200°C, the tower still temperature was 260°C, and the tower top temperature It is 185°C, and the pressure at the top of the tower is -0.1Mpa. The extracted component at the top of the tower accounts for 74% of the mass of the butanol raffinate, the output of C4 accounts for 39% of the mass of the extracted component at the top of the tower, and the output of C8 accounts for 54% of the mass of the extracted component at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com