Method for preparing oxidation-resistant ceramic-matrix composite material capable of resisting 1,200 DEG C

A composite material and ceramic-based technology, which is applied in the field of preparation of ceramic-based composite materials, can solve the problems of complex preparation process, long cycle, easy peeling off of anti-oxidation coating, etc., and achieves low preparation cost, excellent mechanical properties and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

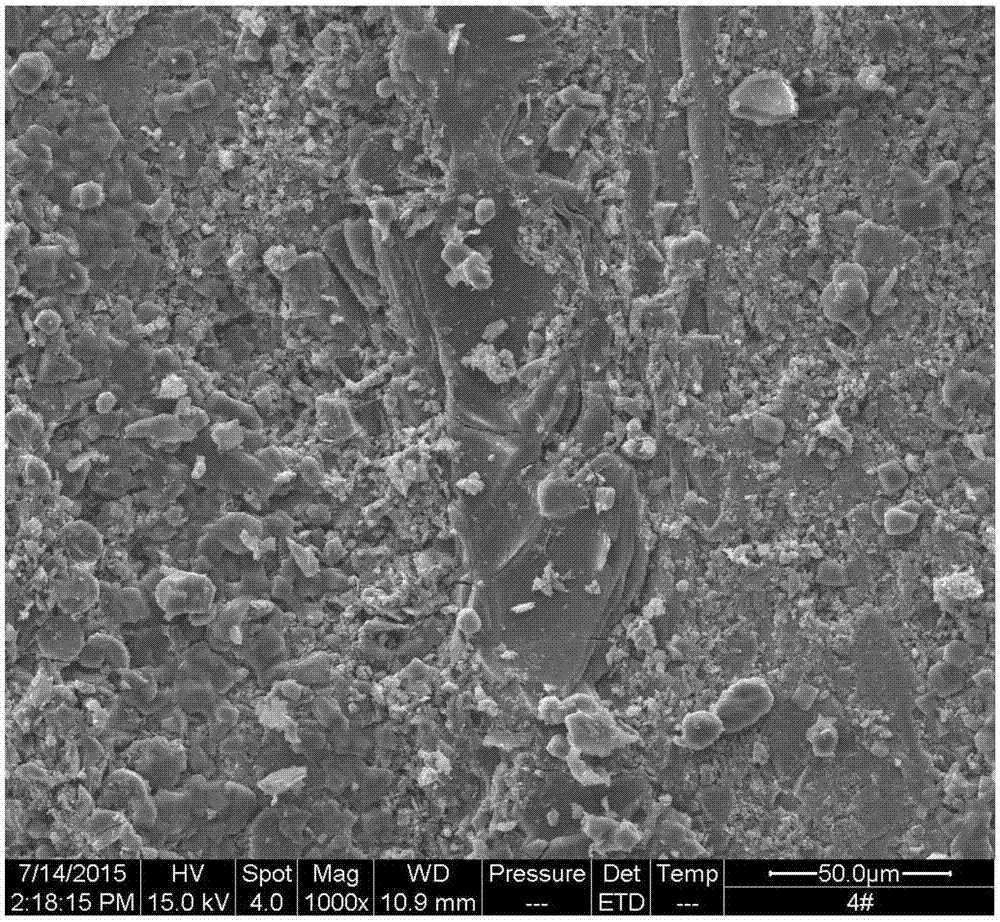

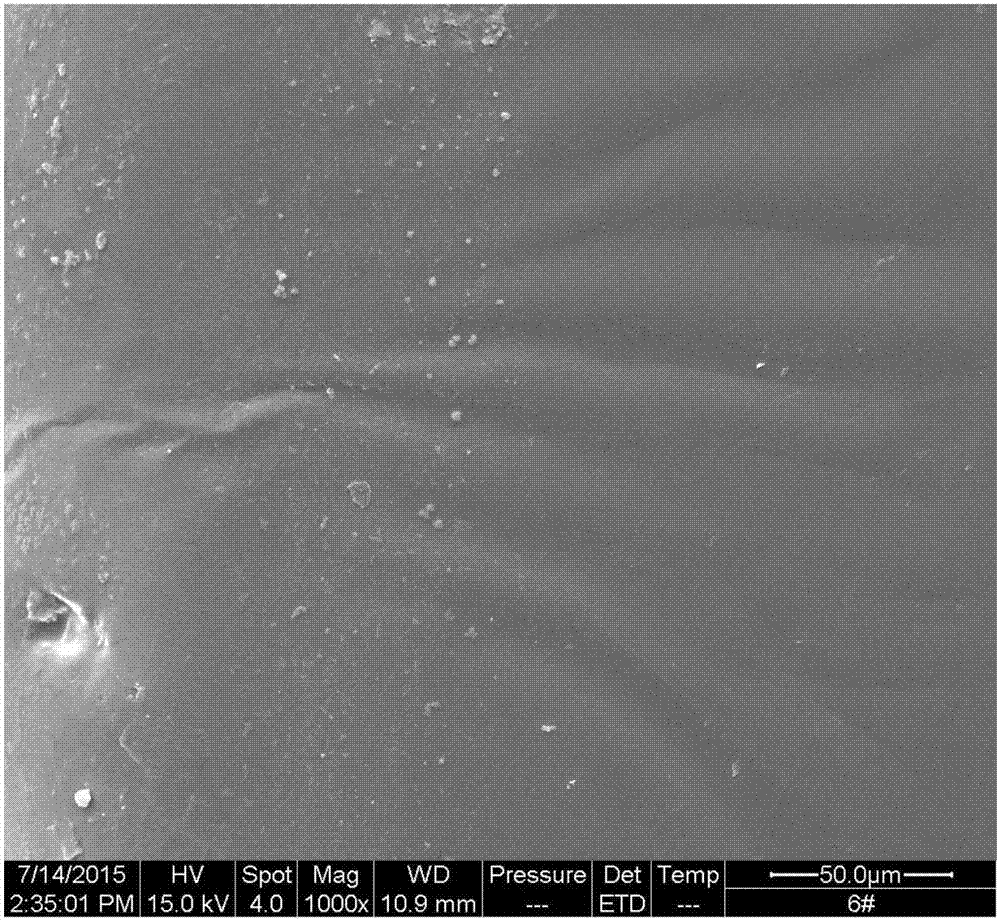

Image

Examples

preparation example Construction

[0024] 1. Preparation of silicon carbide fiber preform: using continuous silicon carbide fiber as raw material, silicon carbide fiber preform is prepared by weaving;

[0025] 2. Preparation of the interface layer: place the silicon carbide fiber preform in a pyrolytic carbon chemical vapor deposition furnace, the pyrolytic carbon source is propane, the temperature is 950 ° C ~ 1100 ° C, the furnace pressure is between 2KPa ~ 4KPa, and the flow rate is 1000ml / min~3000ml / min, deposition time 4h~10h;

[0026] 3. The configuration of the polymer precursor solution: one is to use polycarbosilane as the solute and xylene as the solvent, and the solute accounts for 40-60% of the weight percentage of the precursor solution to configure the polycarbosilane solution; the other is to use polycarbosilane and polyborazine polymer are solutes, xylene is used as a solvent, the solute accounts for 40-60% by weight of the precursor solution, and the polyborazine polymer accounts for 30-50% by...

Embodiment 1

[0035] 1. Preparation of silicon carbide fiber preforms: using continuous silicon carbide fibers as raw materials, silicon carbide fiber preforms are prepared through a 2.5-dimensional weaving process;

[0036] 2. Preparation of the interface layer: place the silicon carbide fiber preform in a pyrolytic carbon chemical vapor deposition furnace, the pyrolytic carbon source is propane, the temperature is 1000°C, the furnace pressure is 2KPa, the flow rate is 2000ml / min, and the deposition time is 4h;

[0037] 3. The configuration of the polymer precursor solution: one is to use polycarbosilane as the solute and xylene as the solvent, and the solute accounts for 50% of the weight percentage of the precursor solution to configure the polycarbosilane solution; the other is to use polycarbosilane Silane and polyborazine polymer are solutes, xylene is used as solvent, solute accounts for 50% of the weight percentage of the precursor solution, polyborazine polymer accounts for 30% of s...

Embodiment 2

[0046] 1. Preparation of silicon carbide fiber prefabricated body: using continuous silicon carbide fiber as raw material, a silicon carbide fiber prefabricated body is prepared through a 3D weaving process;

[0047] 2. Preparation of the interface layer: place the silicon carbide fiber preform in a pyrolytic carbon chemical vapor deposition furnace, the pyrolytic carbon source is propane, the temperature is 1000°C, the furnace pressure is 2KPa, the flow rate is 2000ml / min, and the deposition time is 10h;

[0048] 3. The configuration of the polymer precursor solution: one is to use polycarbosilane as the solute and xylene as the solvent, and the solute accounts for 60% of the weight percentage of the precursor solution to configure the polycarbosilane solution; the other is to use polycarbosilane Silane and polyborazine polymer are solutes, xylene is used as solvent, solute accounts for 60% of the weight percentage of the precursor solution, polyborazine polymer accounts for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com