Toothbrush

a tooth brush and brush handle technology, applied in the field of tooth brushes, can solve problems such as damage to the enamel of teeth, and achieve the effect of facilitating the removal of plaqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

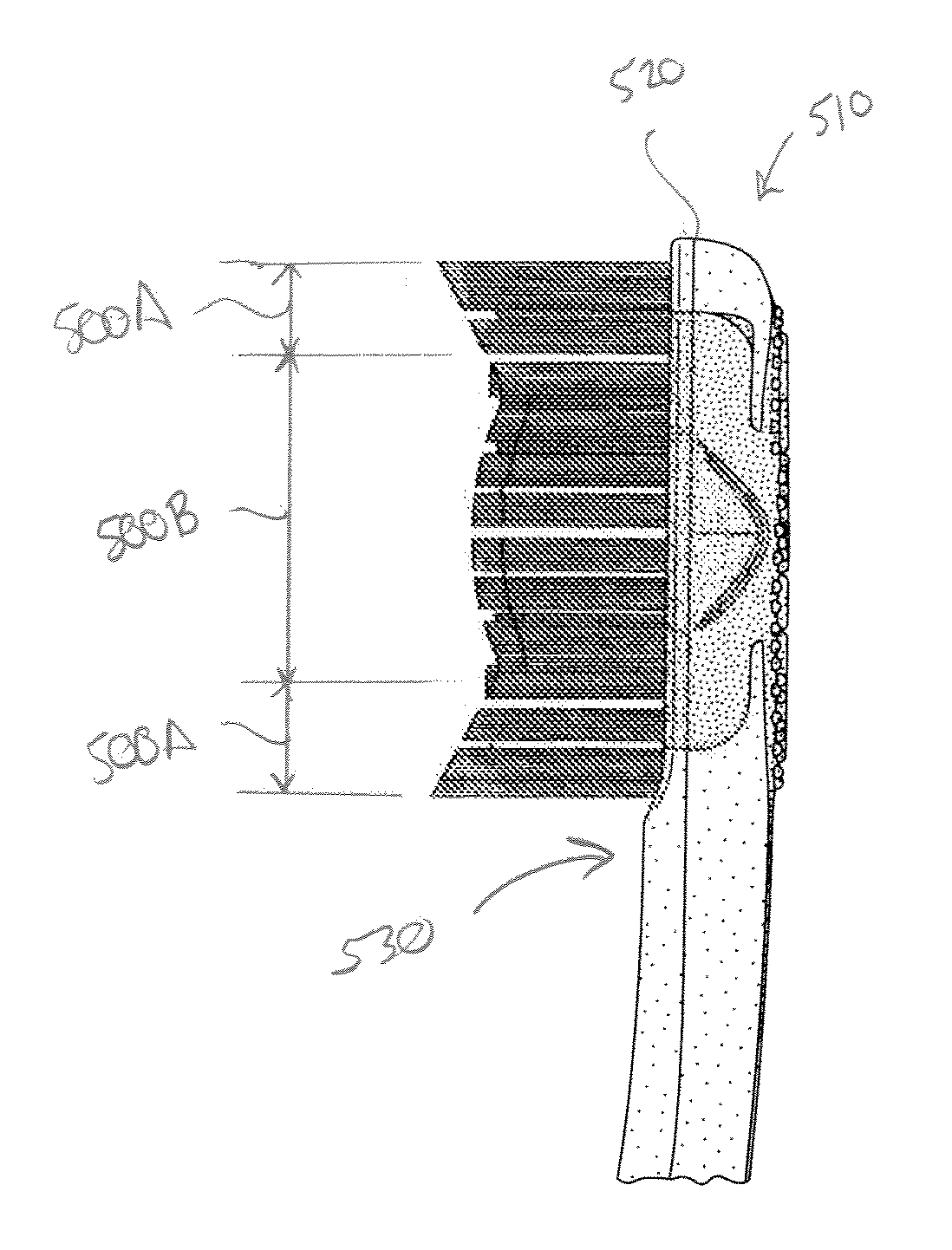

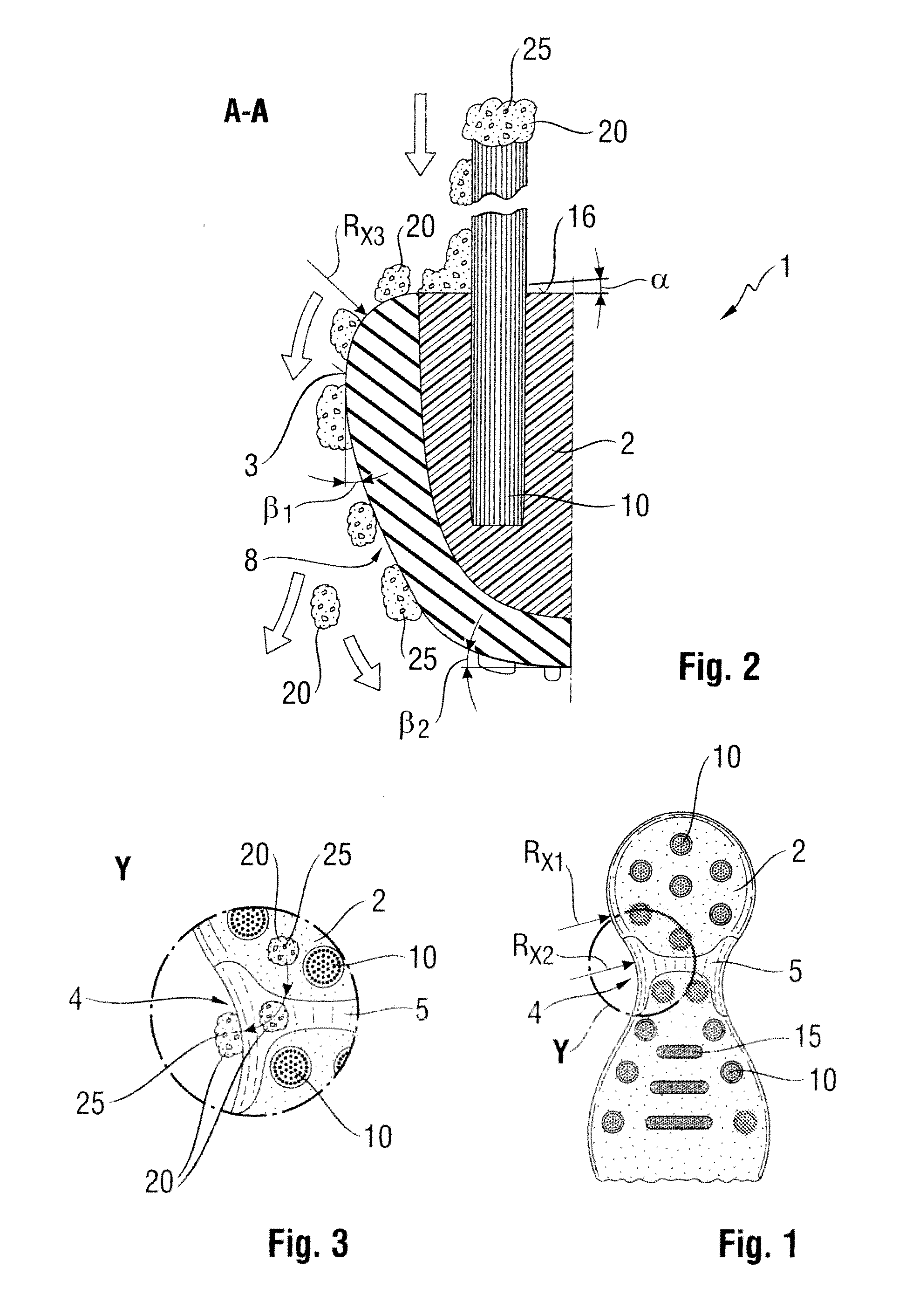

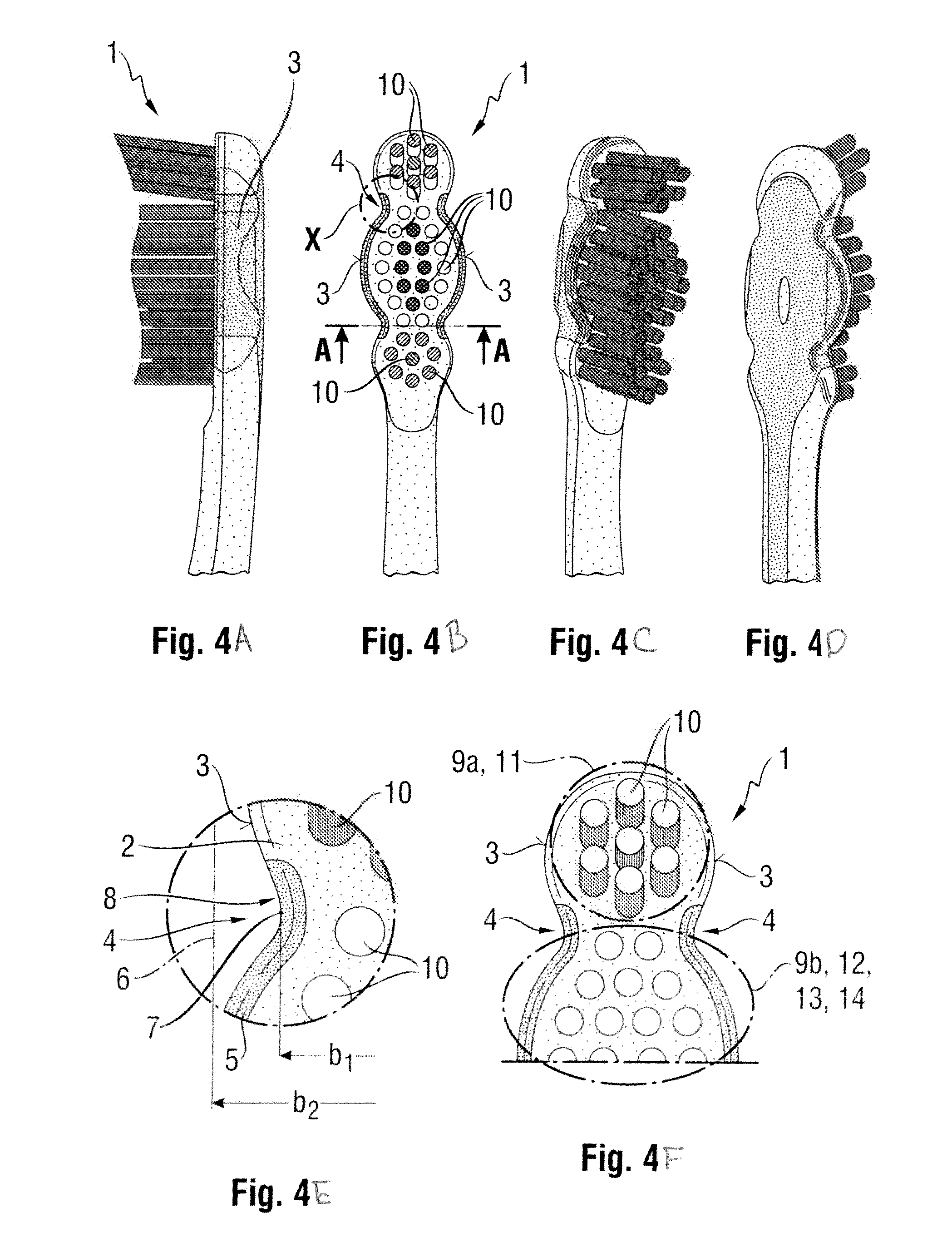

[0048]FIGS. 1-24 G show toothbrush heads or sections thereof that are connected with any toothbrush neck and handle to form a toothbrush. These heads are equally suitable for purely manual toothbrushes and electrically powered ones. Each of the features of the toothbrush heads shown in these embodiments can be designed in reduced form or in a different combination than those represented. Although most embodiments show a tongue scraper having a specific structure on the underside of the head, all of the embodiments can also be made without a tongue scraper or be provided with another tongue scraper structure. Furthermore, some embodiments have elastomer cleaning elements 17 (shown in FIG. 9F)(elastic cleaning elements 17 preferably made of soft material) in combination with bristle tuft cleaning elements, while others have only bristle tuft cleaning elements.

[0049]Referring to FIGS. 1-4F, the toothbrush head 1 made of hard material or of a first component 2 is provided with a lateral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com