Pore self-generation superhard abrasives grinding tool and shaving method thereof

A technology of superabrasives and superabrasive grains, which is applied in the field of precision and ultraprecision grinding, which can solve problems such as increased processing costs, workpiece burns, and high wear ratio, and achieve good durability, precision retention, and low damage The effect of ultra-precision processing and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

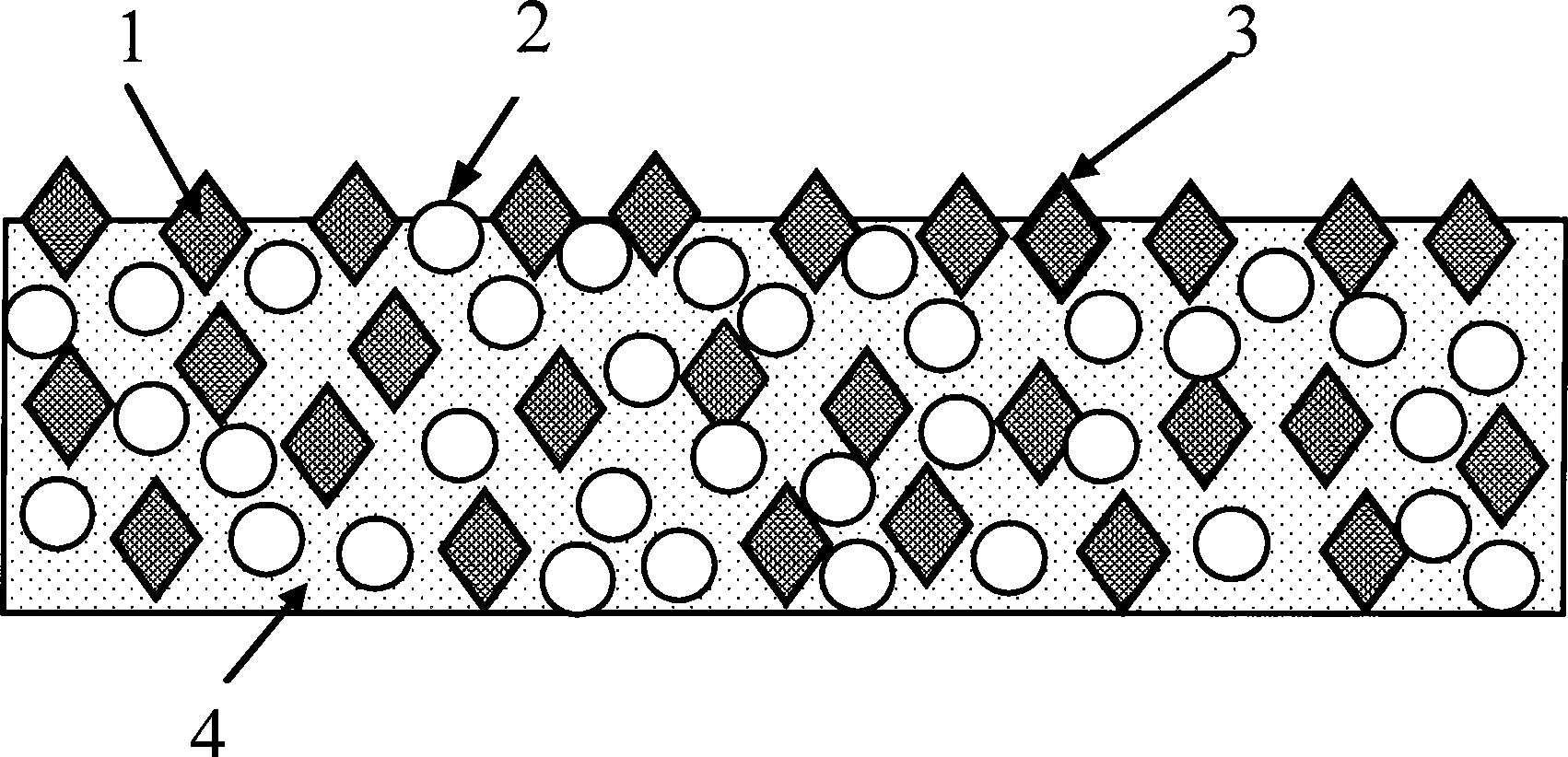

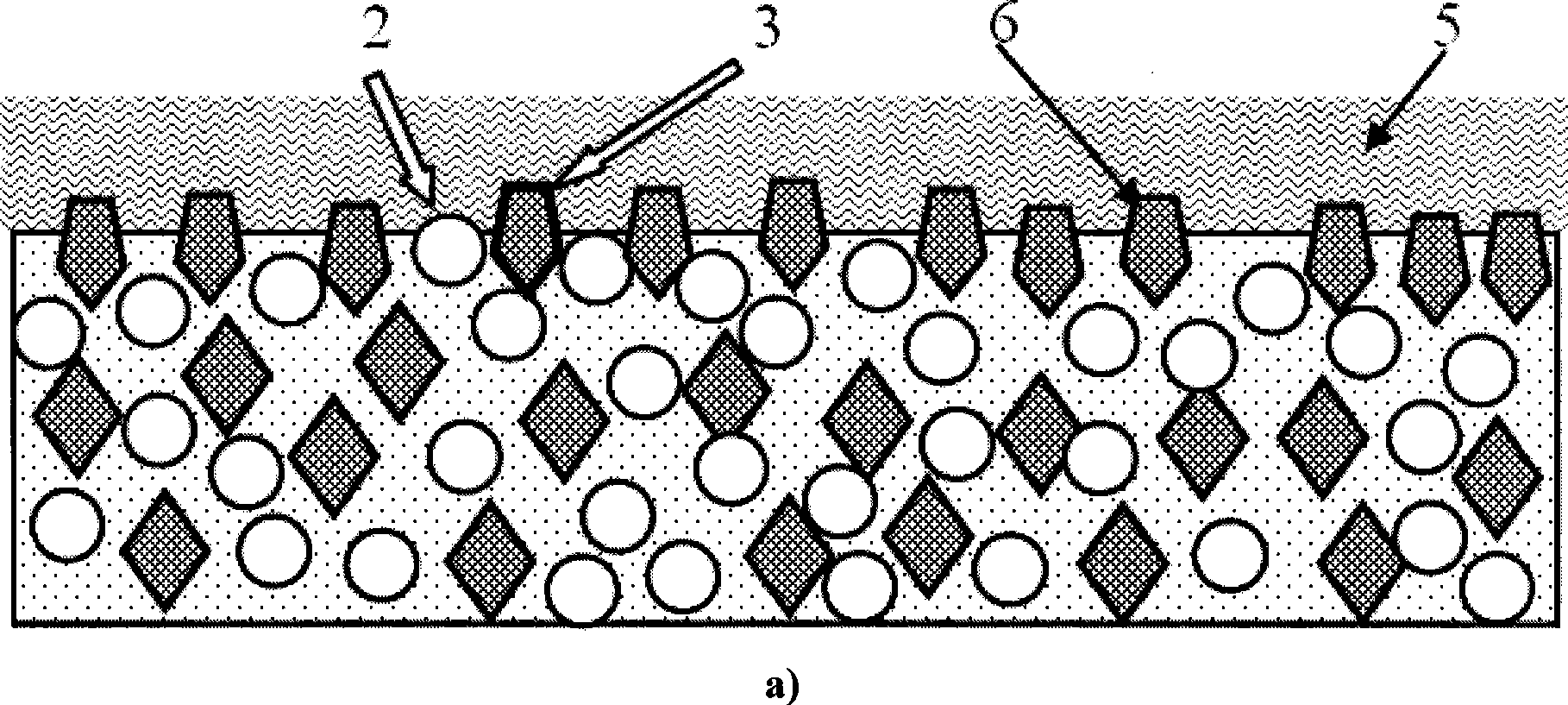

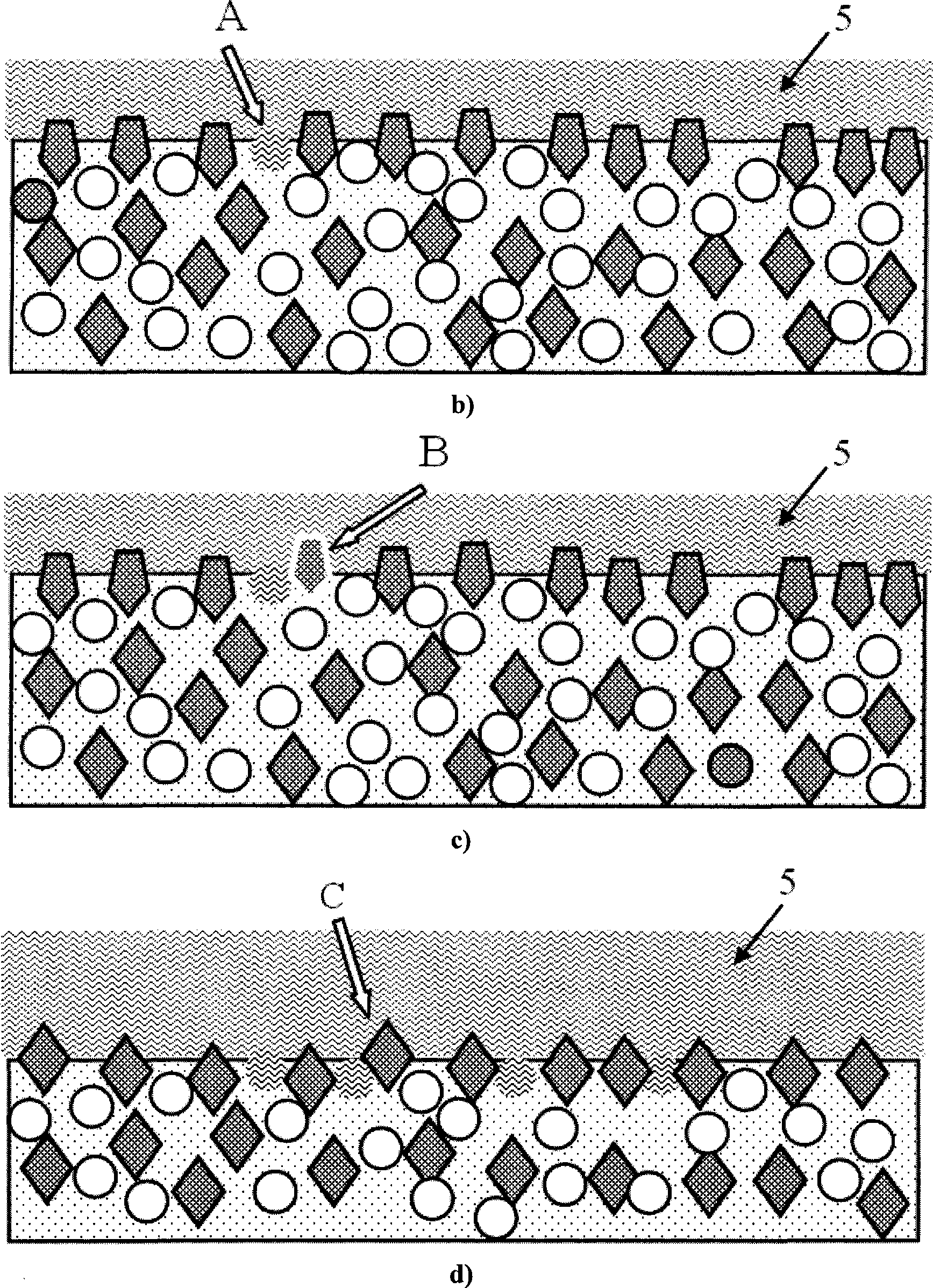

Method used

Image

Examples

Embodiment 1

[0061] In this embodiment, diamond superabrasives (abrasive particle size W0.5-W40), bronze bond (or cast iron bond) are used, the "soluble" filler is selected from a typical metal material—metal Zn, and the solvent is selected from FeCl 3 solution. The concentration of diamond superabrasives is 100%-150%. The soluble filler metal Zn is added to the bond, and the weight of the addition is 20%-100% of the weight of the diamond abrasive, FeCl 3 The solution concentration is 5%-30%. At the same time, the vacuum coating technology can be used to coat metal zinc on the diamond surface according to the needs.

[0062] When trimming, inject FeCl in the processing area 3 solution. Due to the grinding effect of the abrasive tool on the workpiece, the "soluble" filler around the abrasive grains and on the surface of the abrasive tool - Zn will be exposed. Since Zn is more active than Fe, Zn will react with FeCl 3 The solution undergoes a displacement reaction, so that Zn dissolves...

Embodiment 2

[0065] In this embodiment, diamond superabrasives (abrasive particle size W0.5-W40), bronze bond (or cast iron bond) are used, and the "soluble" filler is selected from oxide-silicon dioxide SiO 2 , the solvent is NaOH solution. The concentration of diamond superabrasives is 100%-150%. Soluble filler SiO is added to the binder 2 , the added amount is 20%-100% of the weight of the diamond abrasive, and the pH value of the NaOH solution is about 8-9.

[0066] When trimming, inject hot NaOH solution in the processing area. Due to the grinding effect of the abrasive on the workpiece, the "soluble" filler around the abrasive grains and on the surface of the abrasive - SiO 2 will be exposed. Due to SiO 2 react with NaOH solution to make SiO 2 Dissolved in NaOH solution, forming voids on the surface of the abrasive tool, reducing the holding force of the bond on the abrasive grains, and reducing the structural strength of the bond, so that the passivated diamond abrasive grains...

Embodiment 3

[0069] This embodiment adopts diamond superabrasives (abrasive particle size W0.5-W40), traditional resin binders (such as phenolic resins, etc.), "soluble" fillers select water-based polyvinyl alcohol (PVA) synthetic resins, and solvents select water. The concentration of diamond superabrasive is 50%-75%. A soluble filler PVA synthetic resin is added to the bonding agent, and the added amount is 50%-100% of the weight of the diamond abrasive.

[0070]In the process of processing, cooling water is continuously injected on the surface of the abrasive tool to dissolve the PVA synthetic resin on the surface of the abrasive tool to form pores, so as to improve the self-sharpening performance of the diamond abrasive tool and obtain a good processing effect. The dressing speed of the abrasive tool can be controlled by adjusting the dressing frequency of the abrasive tool during processing, and controlling the dissolution rate of the filler PVA by adjusting the temperature and flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com