Carbide alloy welding wire or welding rod as well as manufacturing method and application thereof

A technology of cemented carbide and manufacturing method, applied in manufacturing tools, welding media, welding equipment, etc., can solve the problems of non-wear resistance, unsatisfactory wear resistance, accelerated wear, etc., to improve corrosion resistance and promote aging hardening. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

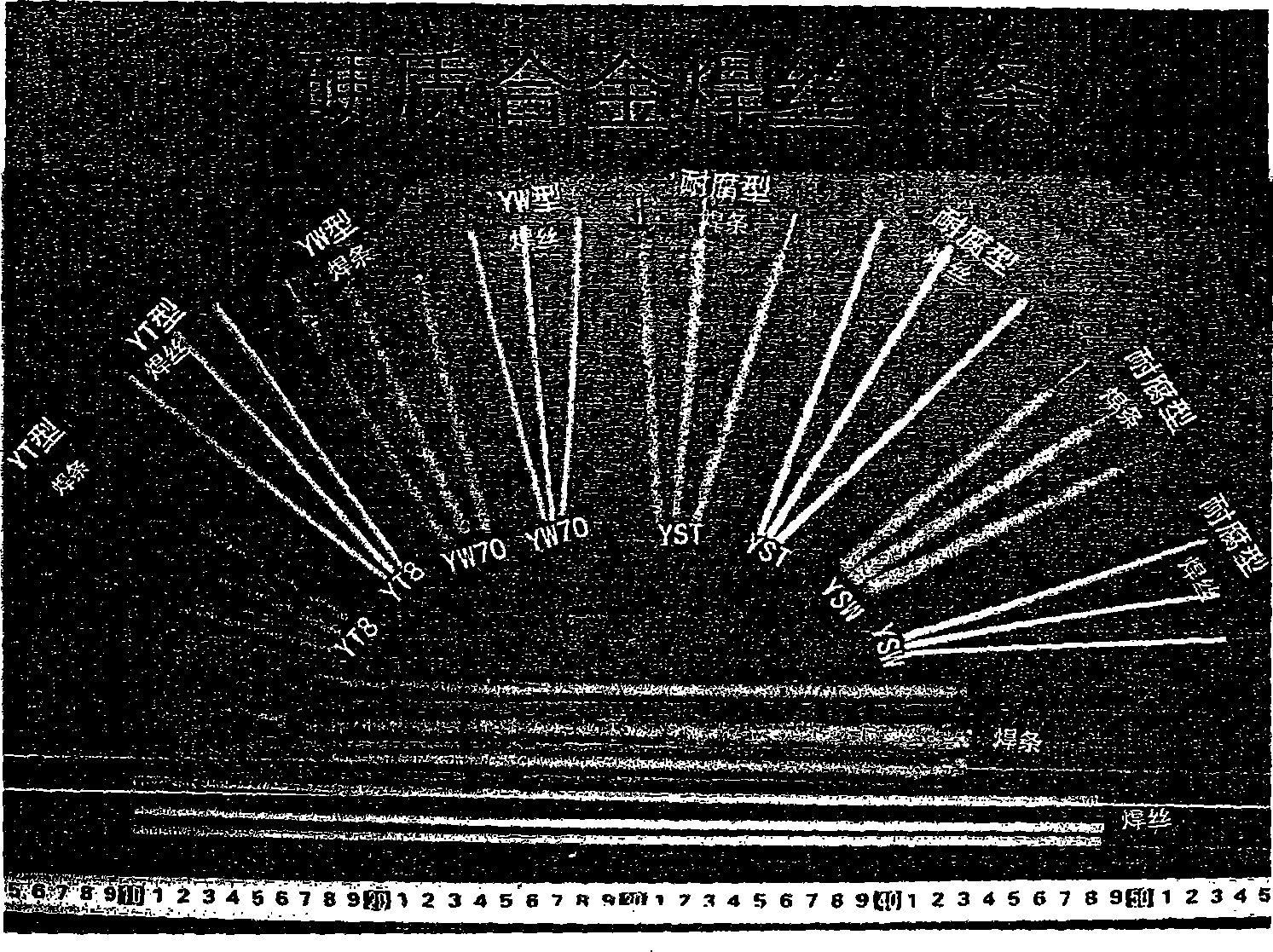

Image

Examples

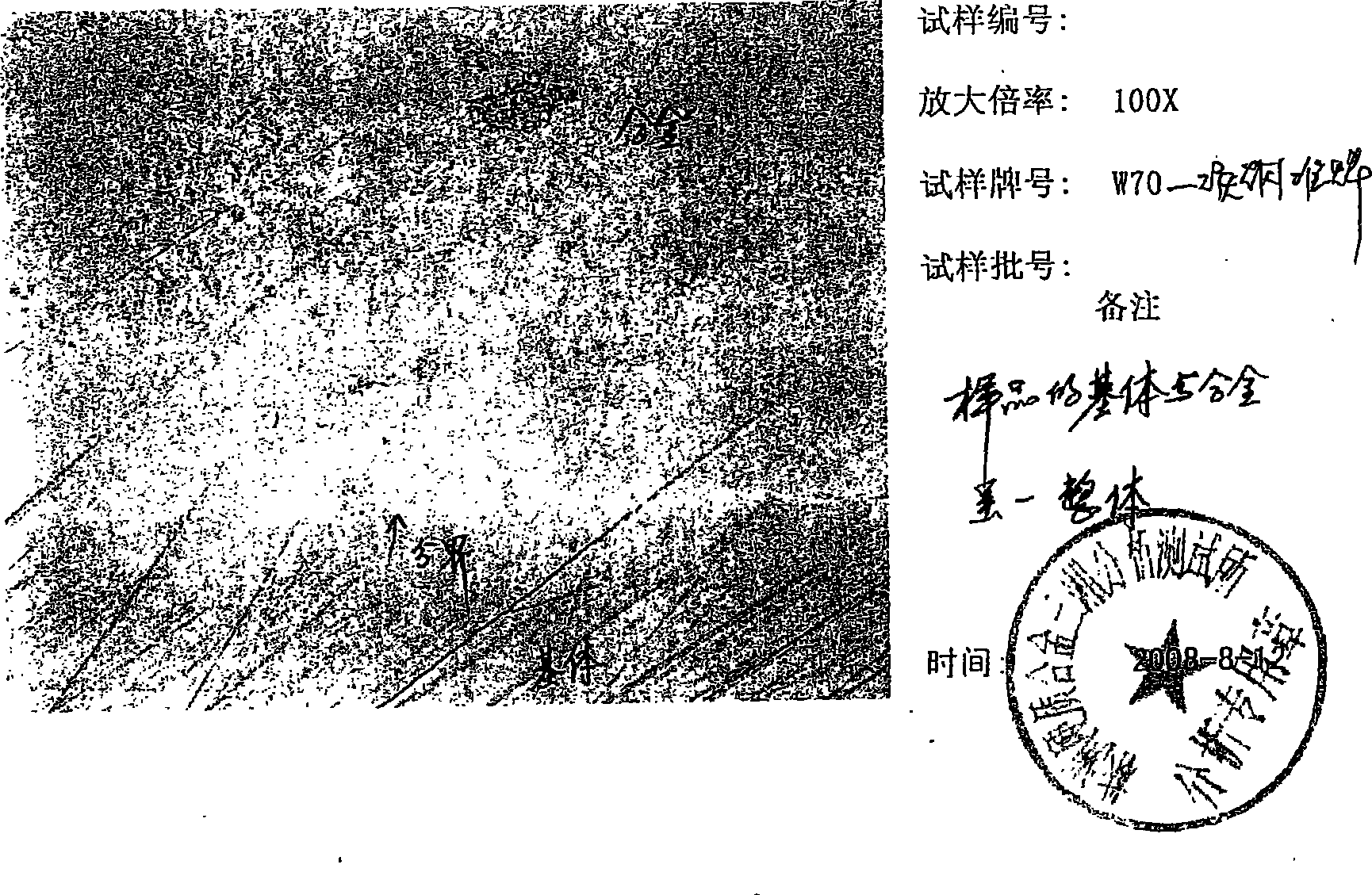

Embodiment 1

[0022] Example 1: Tungsten carbide is used as the hard phase, numbered W70, and its alloy welding wire composition wt%:

[0023] WC Ni Co Mo Cr 3 C 2 Fe VC Cu

[0024] 75 4 2.5 1 0.5 15.8 0.2 1

[0025] After batching, use alcohol as the medium, and carry out ball milling at a ratio of 3:1=ball:material for 24 hours, sieve 100 mesh, dry, sieve 60 mesh, add general forming agent, dry, sieve 60 mesh, press, and vacuum sinter Or hydrogen sintering, the temperature is 1450-1470℃, and the holding time is 45 minutes to make the welding wire.

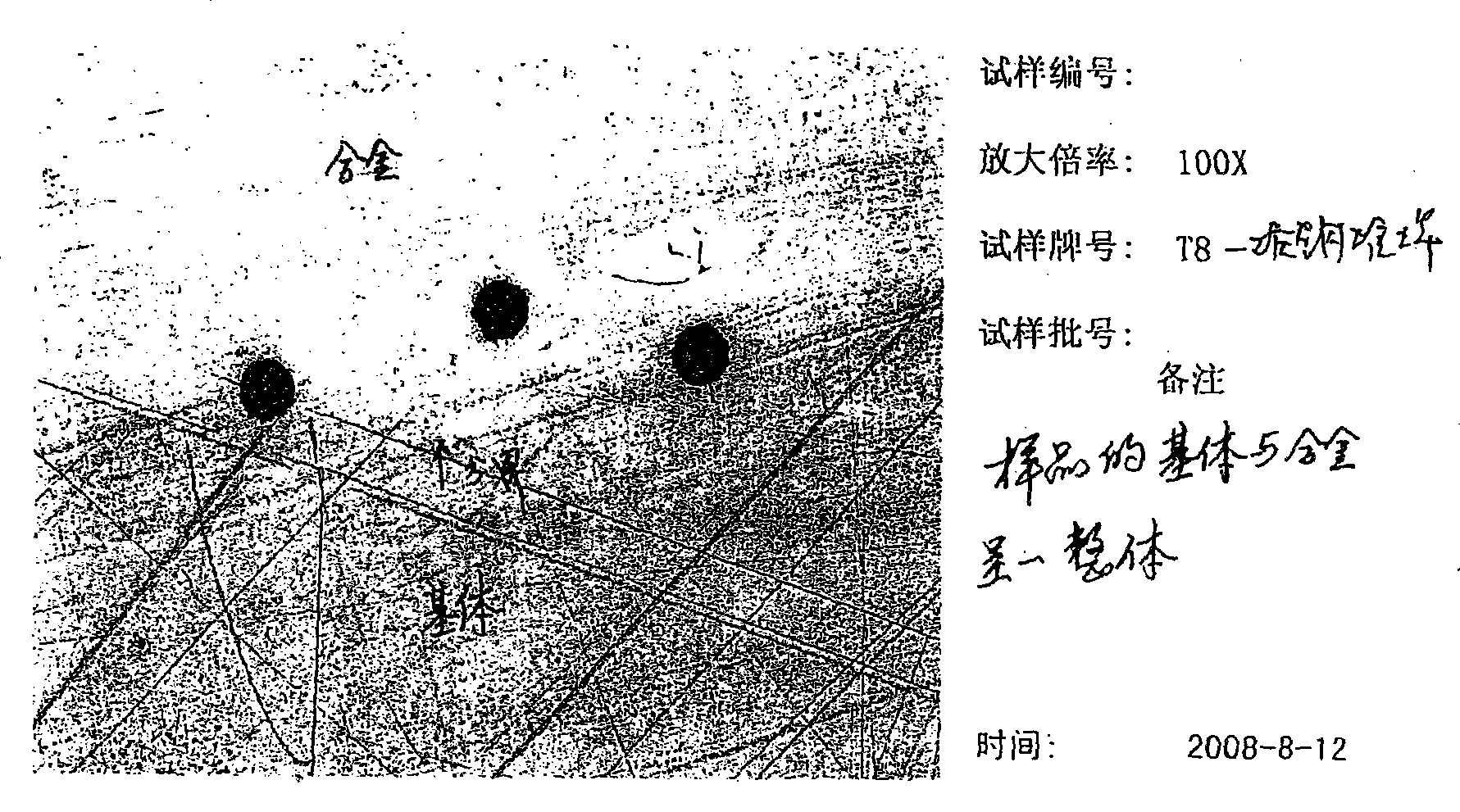

Embodiment 2

[0026] Example 2: A composite of tungsten carbide and titanium carbide is used as the hard phase, numbered T8. Its alloy composition, wt%:

[0027] TiC WC Cr Mo Ni Cu Fe VC

[0028] 40 30 2 2 4 1 20.7 0.3

[0029] After batching, use alcohol as the medium, and carry out ball milling at a ratio of 3:1=ball:material for 24 hours, sieve 100 mesh, dry, sieve 60 mesh, add general forming agent, dry, sieve 60 mesh, press, and vacuum sinter Or hydrogen sintering, the temperature is 1450-1470℃, and the holding time is 45 minutes to make the welding wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com