Plating surface wear resistance tester

A wear-resistant test and electroplating technology, which is applied in the direction of test wear resistance, etc., can solve the problems of inaccurate test results, noise, etc., and achieve the effect of good versatility, improved accuracy, and smooth grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

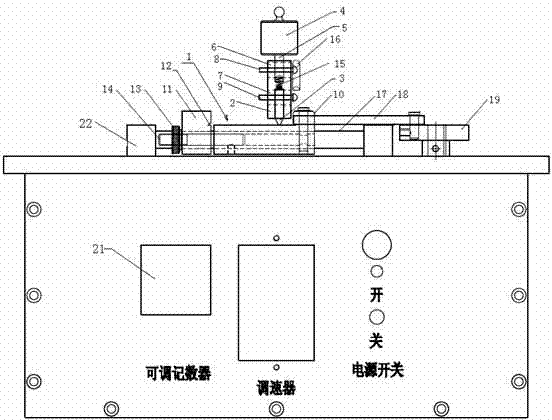

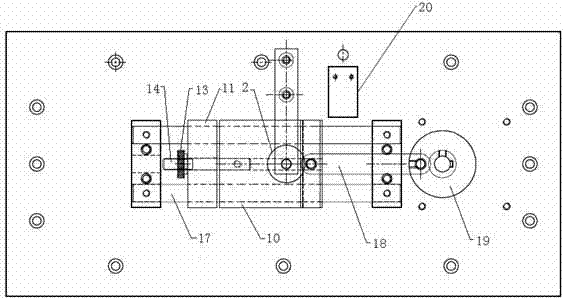

[0027] Such as Figure 1-2 As shown, a kind of electroplating surface wear-resisting testing machine of embodiment 1 comprises sample loading platform 1, and described sample loading platform 1 can fix the sample to be tested; Grinding mechanism, described grinding mechanism is arranged on described loading by support Above the sample stage 1, it includes a sleeve 2 installed on the support, a grinding head 3 installed on the sleeve 2 and a gravity weight 4, and the gravity weight 4 is arranged on the grinding head 3 Above, the grinding head 3 is loaded, of course, the support can be set as a structure adjustable up and down; the driving mechanism, the driving mechanism drives the sample loading table 1 or the grinding mechanism to move back and forth relatively, The reciprocating sliding friction is generated between the grinding head 3 and the sample to be tested; the lower end of the gravity weight 4 has a fixed rod 5, and the upper end of the sleeve 2 is suitable for inser...

Embodiment 2

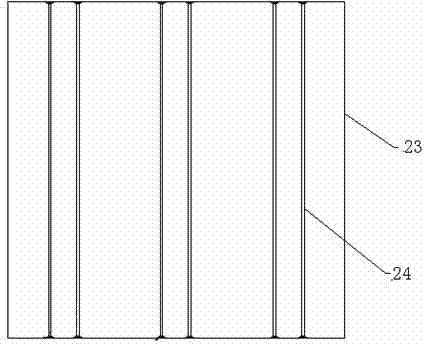

[0036] Such as image 3 As shown, when the sample to be tested is a metal wire 24 provided with an electroplated layer, the snap-in groove 12 of the sample loading platform 1 is also provided with a detachable substrate on which the metal wire 24 is fixed. . In this embodiment, the substrate is a copper sheet 23, and the metal wire 24 is fixed on the substrate by welding. The metal wire can be palladium gold wire or gold wire or the like.

Embodiment 3

[0038] Such as Figure 4 As shown, of course, the substrate can also be punched, thereby directly forming several metal wires 24 on the substrate, and then an electroplating layer is arranged on the formed metal wires 24, and finally the substrate is arranged on the sample stage. Available for testing. In this embodiment, the base may be a copper sheet 23 .

[0039] Working process of the present invention:

[0040] The invention can not only be used to test the wear resistance of the object plane, but also can test the wear resistance of tiny coated wires, such as palladium gold wire or gold wire. Only when testing the wear resistance of the plane of the item, the test item can be directly clamped on the sample loading platform 1; when testing the coated wire, it is necessary to fix the electroplated coated wire, such as palladium gold wire or gold wire, on the On the copper sheet 23, load it on the sample loading platform 1 again, and align the palladium wire for the wear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com