Pressurized grouting test device and method for rock specimens

A technology of grouting under pressure and a test device, which is applied in soil material testing, material inspection products, etc., can solve the problems of difficult production and little practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

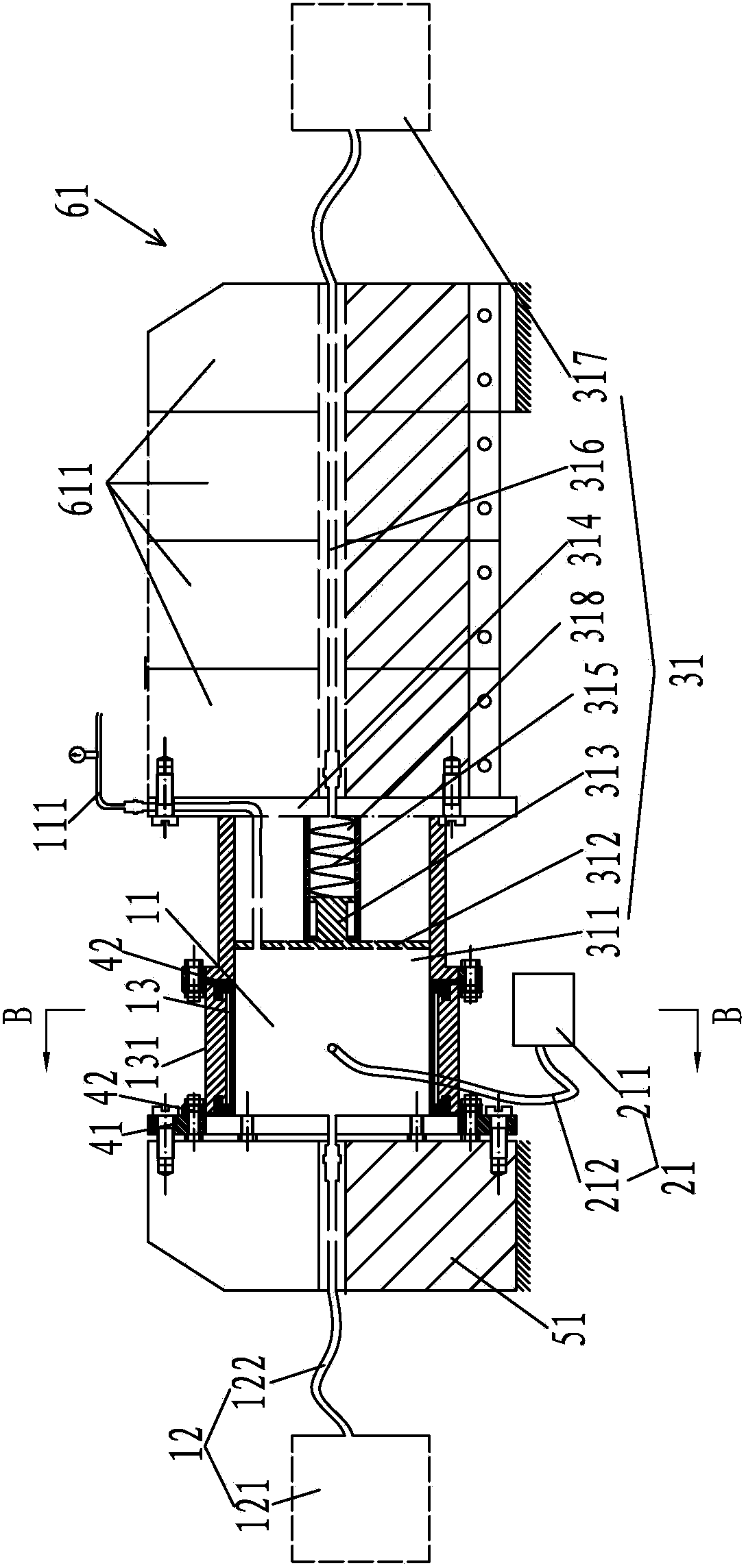

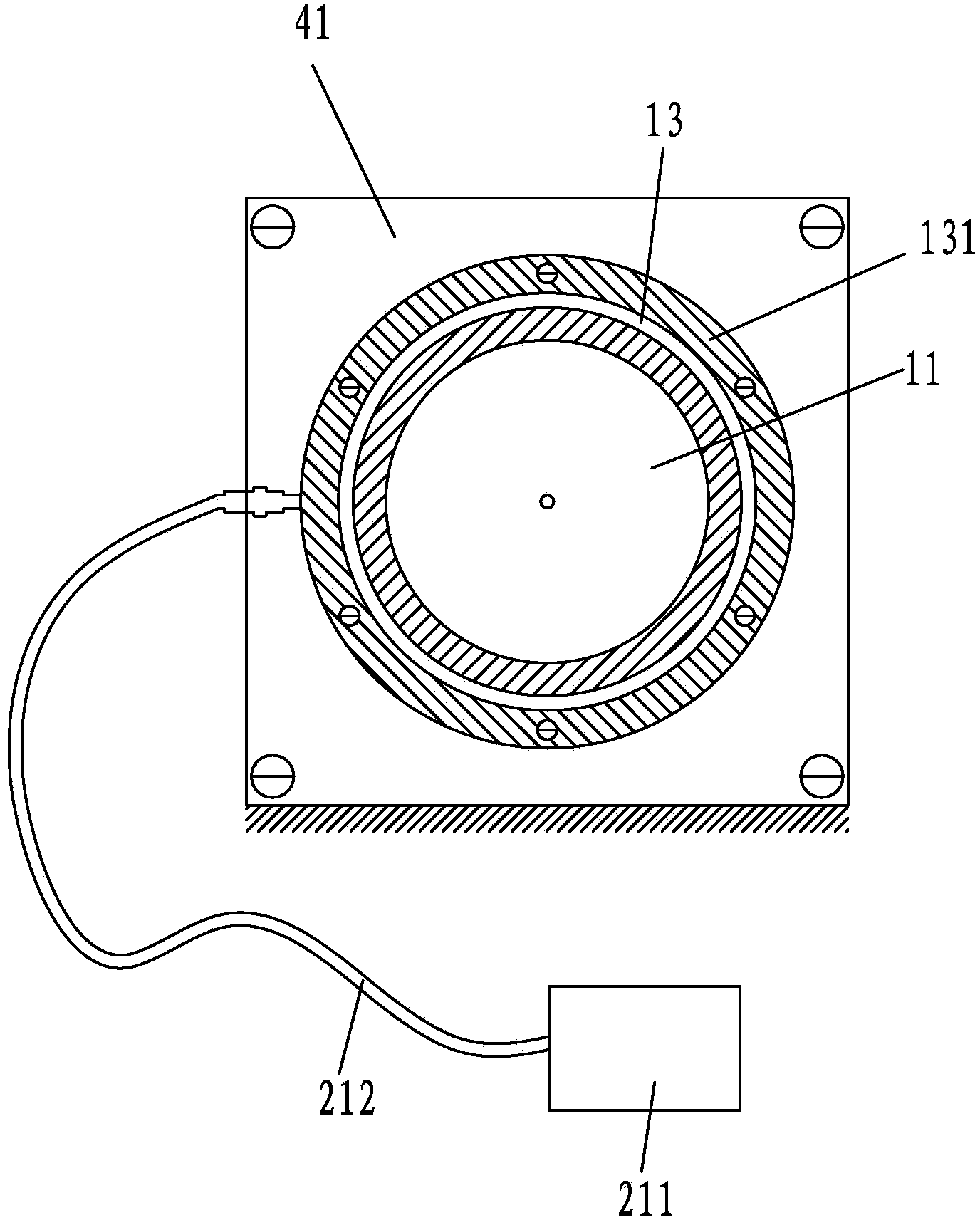

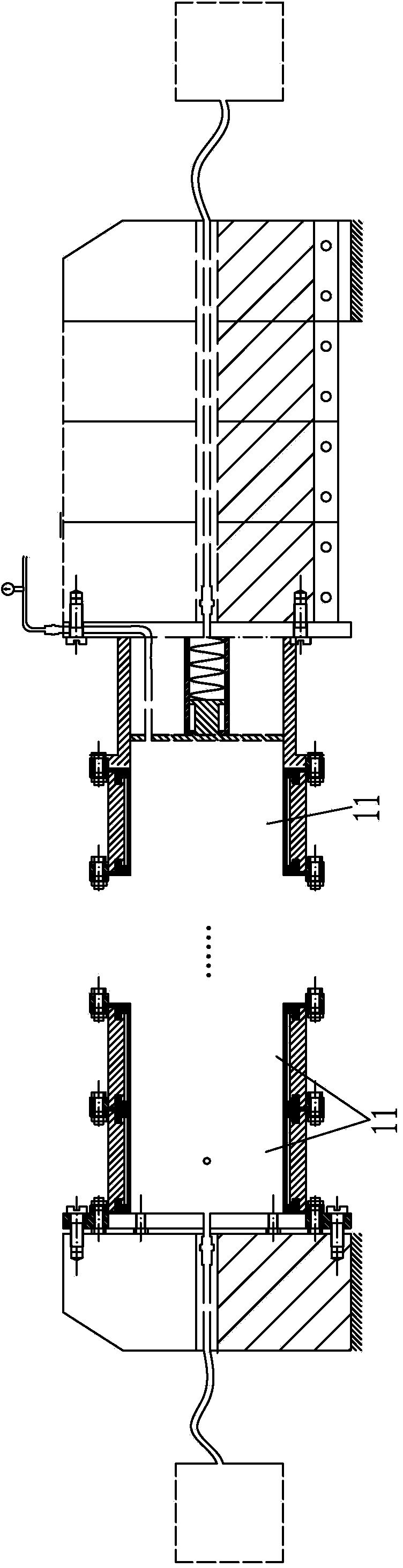

[0019] Such as figure 1 As shown, the present invention is used for the pressure grouting test device of rock test piece, comprises test piece cavity 11 and the grouting device 12 that is communicated with test piece cavity 11, and the internal diameter of test piece cavity 11 is 190mm, and the height of cavity body is 130mm, test The piece cavity 11 is connected with an exhaust and a slurry discharge pipeline 111, and a pressure gauge is arranged on the exhaust and slurry discharge pipeline 111, such as figure 1 , 2 As shown, the lateral periphery of the specimen chamber 11 is provided with a pressure chamber cylinder 131, the pressure chamber cylinder 131 is made of steel, and the left and right ends of the lateral side wall of the specimen chamber 11 are respectively embedded in the pressure chamber cylinder 131. Left and right ends, and there is a gap between the middle part of the pressure chamber cylinder 131 and the middle part of the lateral side wall of the test piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com