Retaining apparatus

A technology for holding appliances and processing tools, which is applied in the direction of manufacturing tools, metal processing equipment, optical surface grinders, etc., and can solve the problems of easy falling off of lenses, difficulty in rotating the lens holding appliance and lens, and wear of the outer cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

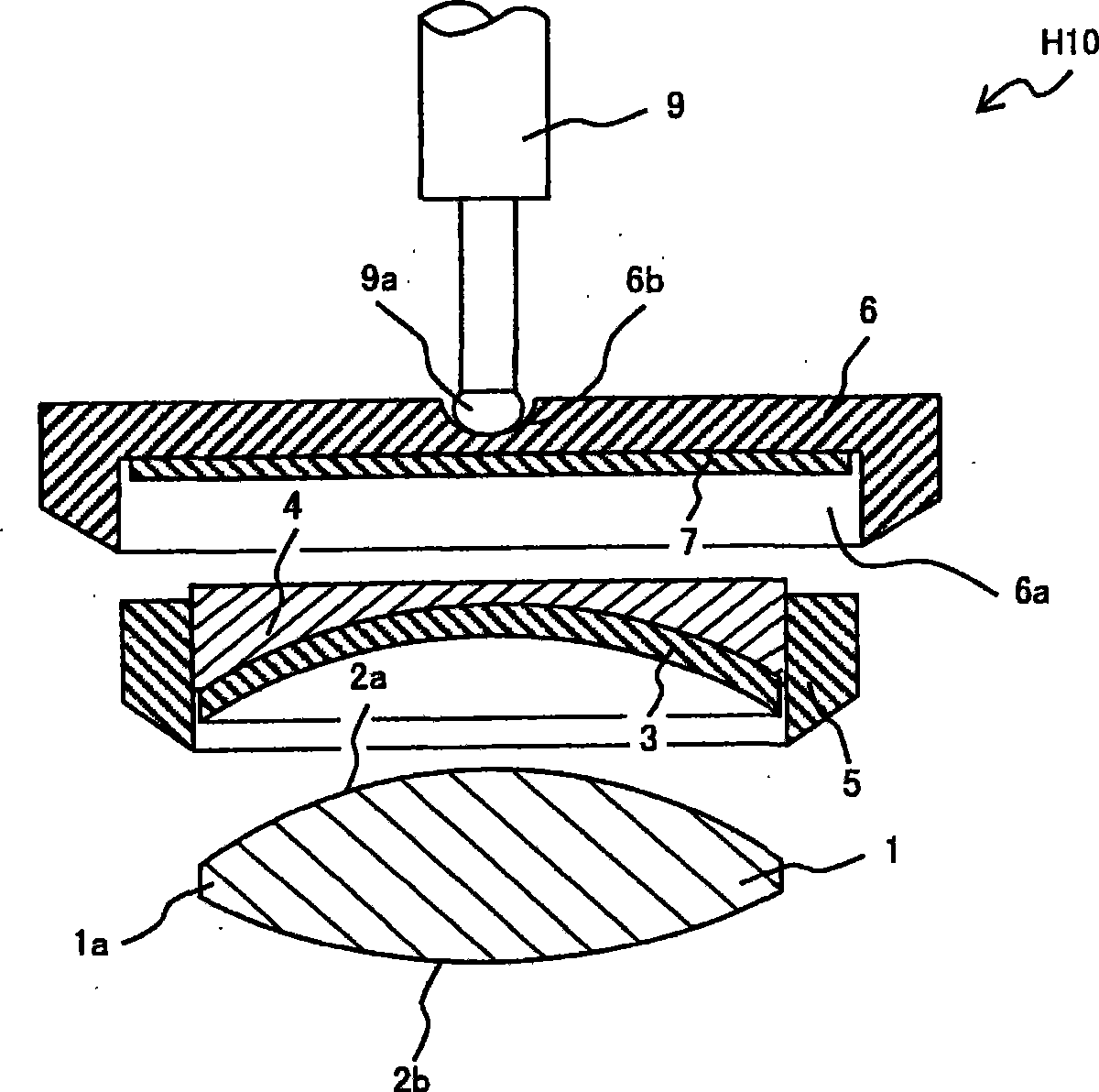

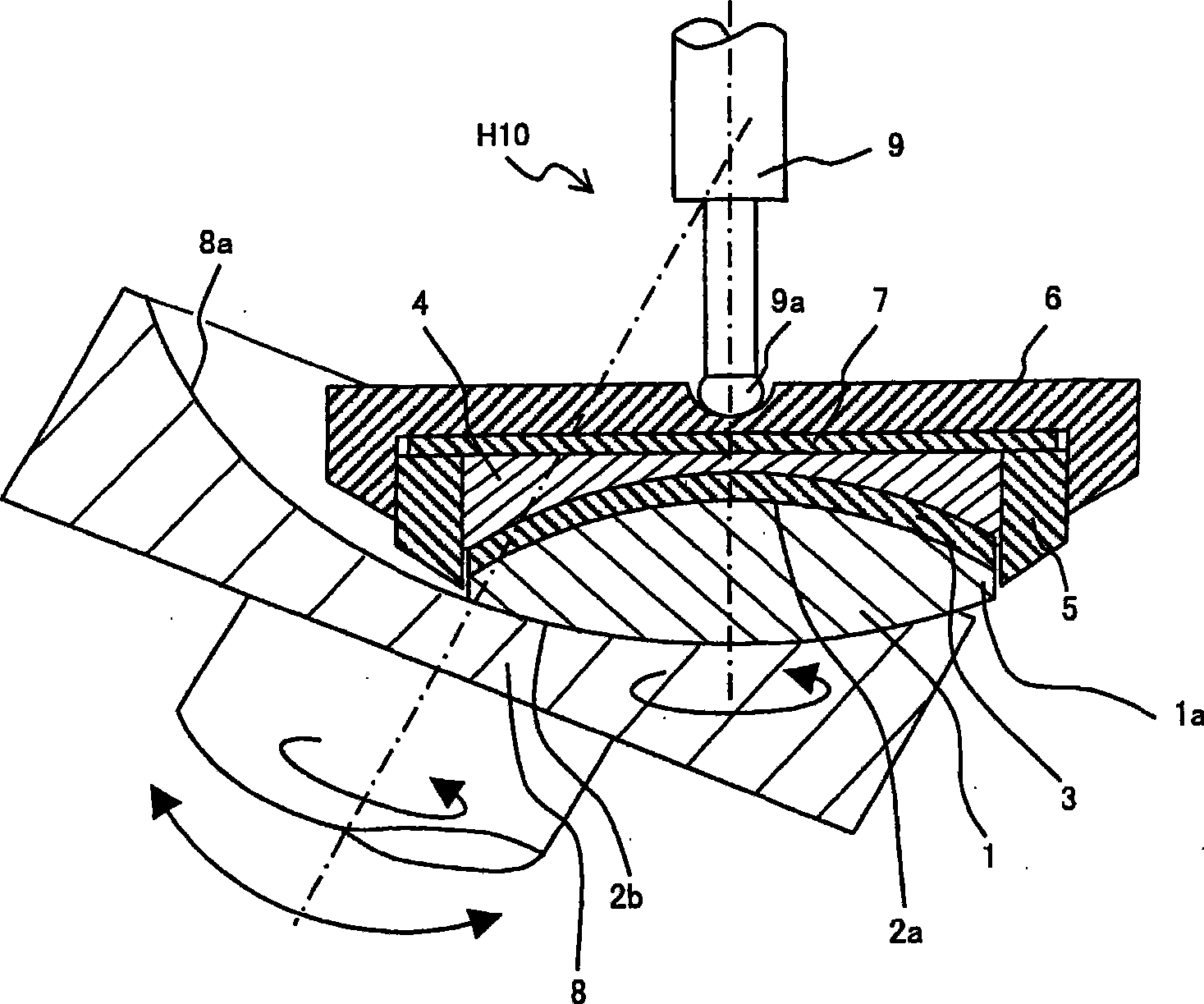

[0101] image 3 It is a cross-sectional view showing an example of the structure and function of the holder as an embodiment of the present invention. The holder H11 disclosed in Embodiment 1 is the above-mentioned Figure 1A and Figure 1B The holder H10 shown in the above example is obtained more concretely, and the same reference numerals are assigned to the common members, and repeated explanations are omitted.

[0102] Should image 3 It shows the situation where lens 1 such as a convex meniscus lens (convex meniscus lenses) is polished by using the holder H11 of this embodiment via the pin 9 used in the conventional grinder.

[0103] (structure)

[0104] A sheet-like member 3 made of superelastic polyurethane having a large coefficient of friction is fastened to the supporting member 4 so as to be in contact with the holding surface 2 a of the lens 1 . In order to make the supporting member 4 support the holding surface 2a of the lens 1, the holding surface 2a has a ...

Embodiment approach 2

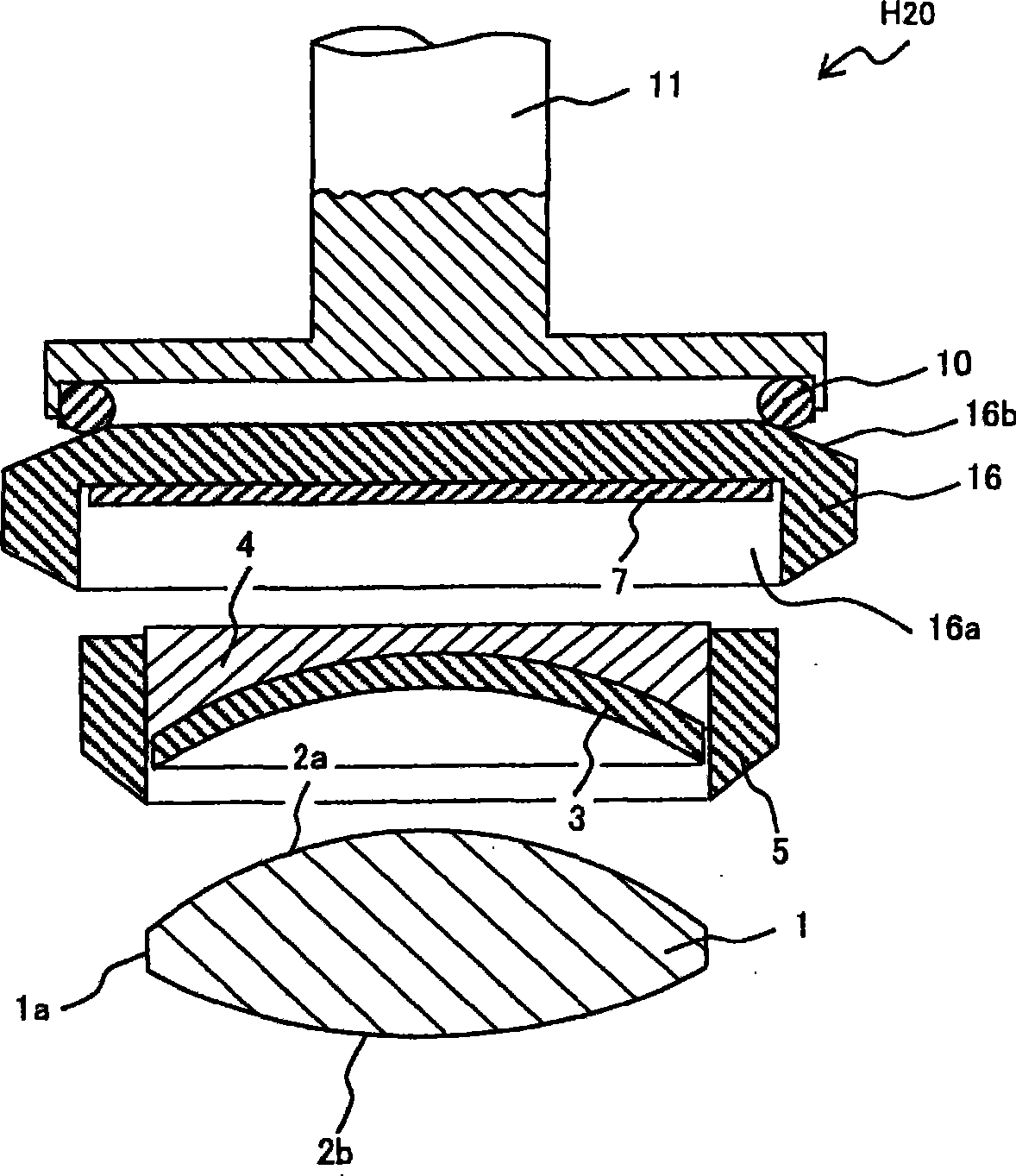

[0133] Figure 4 It is a cross-sectional view showing an example of the structure and function of a holder which is another embodiment of the present invention.

[0134] Should Figure 4 The structure of the holder H21 exemplified in is, for example, corresponding to the lens 1 which is a convex meniscus lens, and the above-mentioned Figure 2A and Figure 2B The structure obtained by making the structure of the holder H20 shown in the example more concrete.

[0135] which is, Figure 4 does not support the lens 1 in a pin structure capable of freely tilting and simultaneously pressing the lens holder, but represents the situation that in the holding unit that presses the lens holder into a freely tilting movement depending on the deformation of the elastic member, The holder H21 of this embodiment is attached, and the convex meniscus lens is ground or lapped.

[0136] about the above Figure 2A and Figure 2B The illustrated holder H20 has components with the same mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com