Control device and method of electrolytic current in grinding process of ELID

An electrolytic current and control device technology, which is applied in the parts of grinding machine tools, abrasive surface adjustment devices, computer control, etc. The effect of constant state of oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

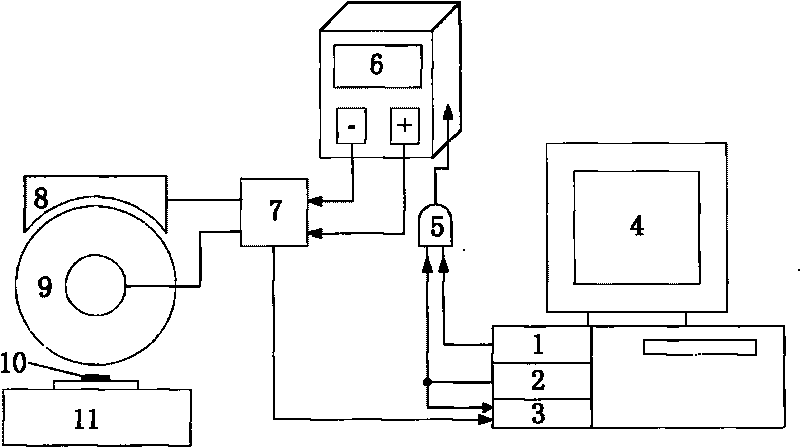

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

[0021] In the figure: 1 and 2 are pulse signal generation cards, 3 is a data acquisition card, 4 is a computer, 5 is an AND gate drive circuit, 6 is a pulse power supply, 7 is a Hall sensor, 8 is an electrode, 9 is a cast iron grinding wheel, 10 11 is a workpiece, and 11 is a workbench.

[0022] The first pulse signal generation card (AC6651, Beijing Shuangnuo Measurement and Control Co., Ltd.) 1, the second pulse signal generation card (AC6651, Beijing Shuangnuo Measurement and Control Co., Ltd.) 2 and the data acquisition card 3 are installed in the computer host 4, and the computer host 4 Connect the AND gate drive circuit 5, the drive circuit 5 is connected to the pulse power supply 6, and the Hall sensor (LA28-NP, Beijing Laim Electronics Co., Ltd.) 7 is respectively connected to the data acquisition card 3, the electrode 8, the cast iron grinding wheel 9 and the data acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com