High-precise ball highly-efficient grinding and polishing processing method

A processing method and high-precision technology, applied in grinding/polishing equipment, grinding machine tools, grinding devices, etc., can solve the problems of complex processing device and control, low sphericity and processing efficiency, poor processing consistency, etc., and achieve simplified structure. , Fast correction of spherical error, uniform grinding/polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

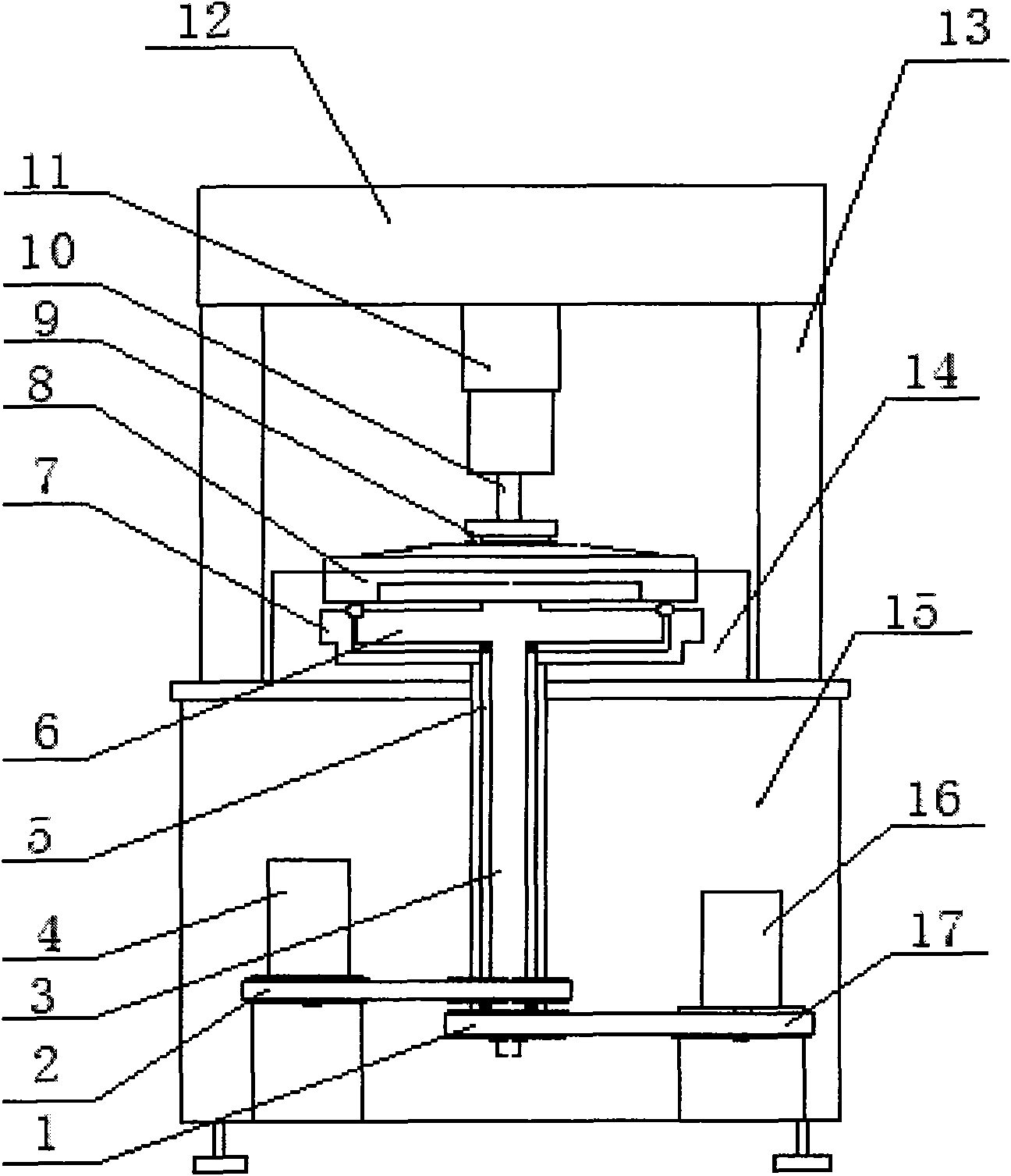

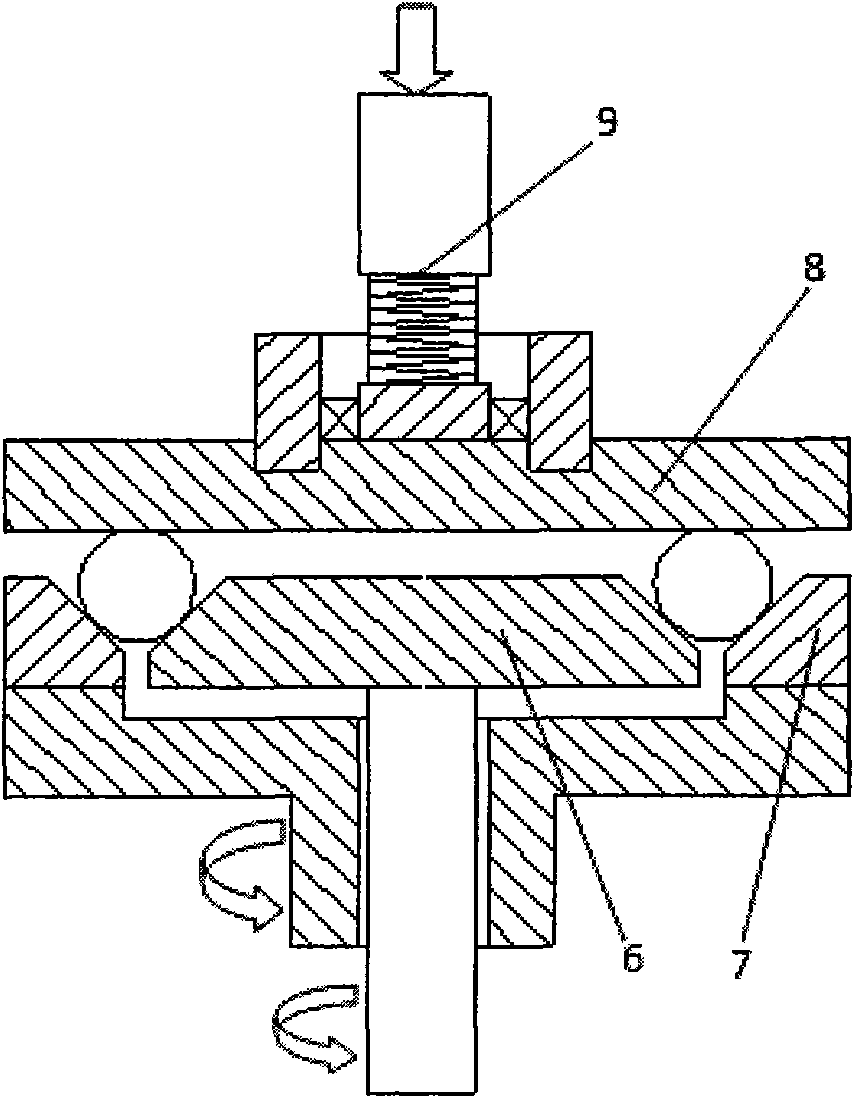

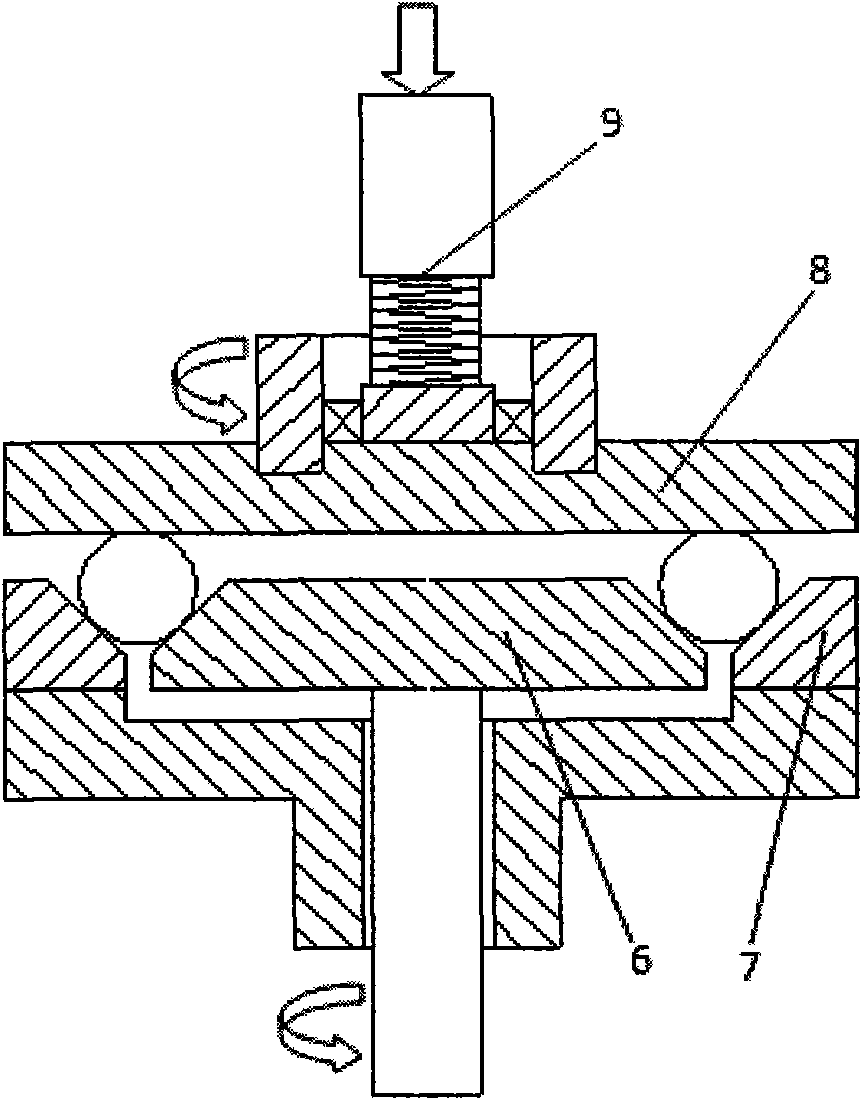

[0037] see figure 1 , figure 2 , Figure 5 and Figure 6 , a high-precision ball high-efficiency grinding / polishing processing method, in the processing equipment for realizing the processing method, the V-shaped groove structure is formed by the conical grinding surface on the outside of the inner disc of the lower grinding disc and the conical grinding surface on the inner side of the outer disc of the lower grinding disc , the load and pressure device acts on the ball blank through the upper grinding disc, the V-shaped groove structure and the upper grinding disc together constitute three processing contact points of the grinding ball, the upper grinding disc, the outer disc of the lower grinding disc and the inner disc of the lower grinding have the same rotary shaft; in the upper grinding disc, the lower grinding disc outer disc and the lower grinding inner disc, the rotating shafts of the two discs are respectively driven by motors;

[0038] Set the three processing ...

Embodiment 2

[0045] see figure 1 , image 3 , Figure 5 and Figure 6 In this embodiment, the inner disc of the lower grinding disc and the upper grinding disc are respectively driven by two different motors.

[0046] The high-efficiency grinding / polishing device used in the present embodiment comprises an upper grinding disc 8, a lower grinding outer disc 7, an inner disc 6 of the lower grinding disc, an inner disc drive motor 16 of the lower grinding disc, an inner disc transmission device 1 and 17, lower grinding disc inner disc main shaft 3, lower grinding disc outer disc drive motor 4, lower grinding disc outer disc transmission device 2, lower grinding disc outer disc main shaft 5, pressure devices 9 and 10, beam 12, locking mechanism 11, column 13. The V-shaped groove structure is formed by the conical grinding surface on the outside of the inner disc 6 of the lower grinding disc and the conical grinding surface on the inner side of the outer disc 7 of the lower grinding disc. C...

Embodiment 3

[0049] see figure 1 , Figure 4-Figure 6 In this embodiment, the outer disc of the lower grinding disc and the upper grinding disc are respectively driven by two different motors.

[0050] The high-efficiency grinding / polishing device used in the present embodiment comprises an upper grinding disc 8, a lower grinding outer disc 7, an inner disc 6 of the lower grinding disc, an inner disc drive motor 16 of the lower grinding disc, an inner disc transmission device 1 and 17, lower grinding disc inner disc main shaft 3, lower grinding disc outer disc drive motor 4, lower grinding disc outer disc transmission device 2, lower grinding disc outer disc main shaft 5, pressure devices 9 and 10, beam 12, locking mechanism 11, column 13. The V-shaped groove structure is formed by the conical grinding surface on the outside of the inner disc 6 of the lower grinding disc and the conical grinding surface on the inner side of the outer disc 7 of the lower grinding disc. Contact points A, B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com