Knife grinder for grinding formed blade

A knife sharpening device and blade technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of cumbersome procedures, low efficiency, and heavy workload of workers, so as to simplify the processing process, improve work efficiency, and ensure grinding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

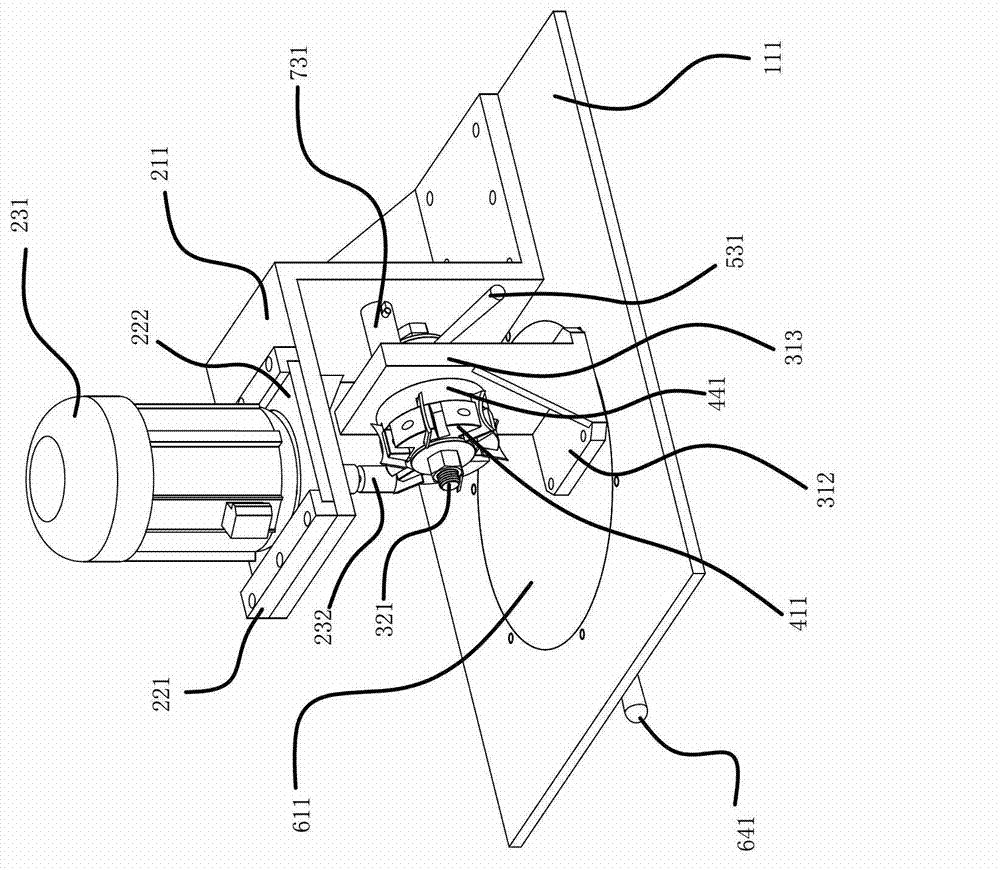

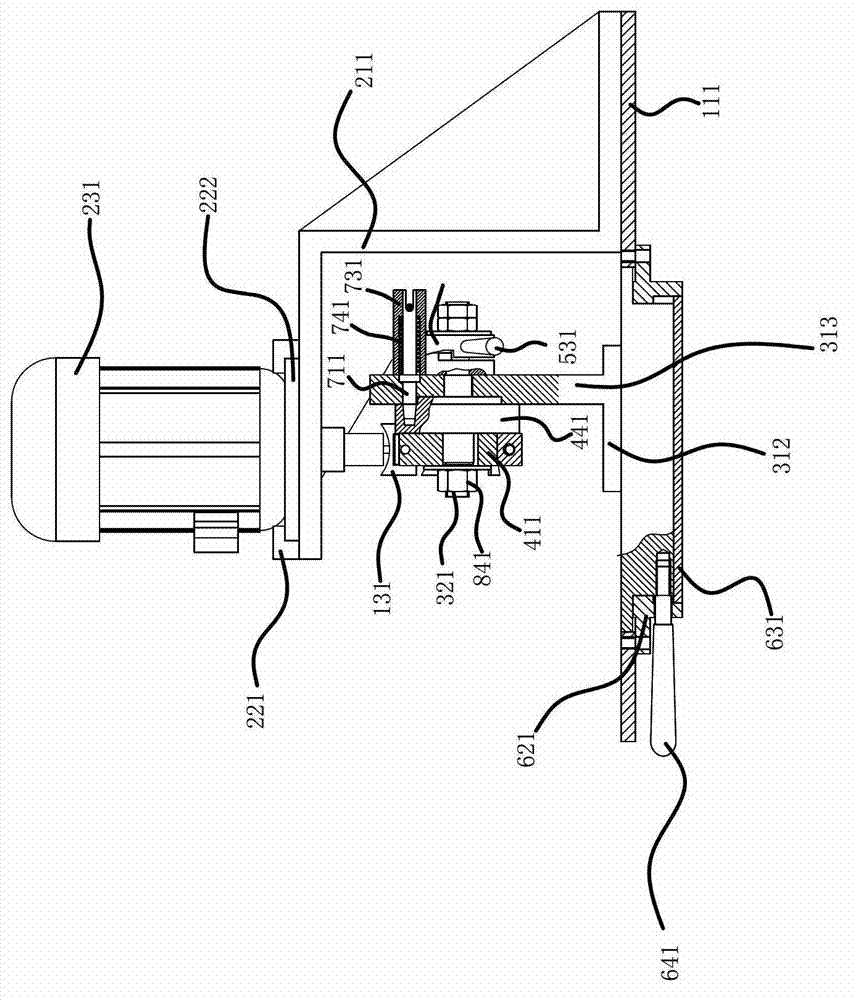

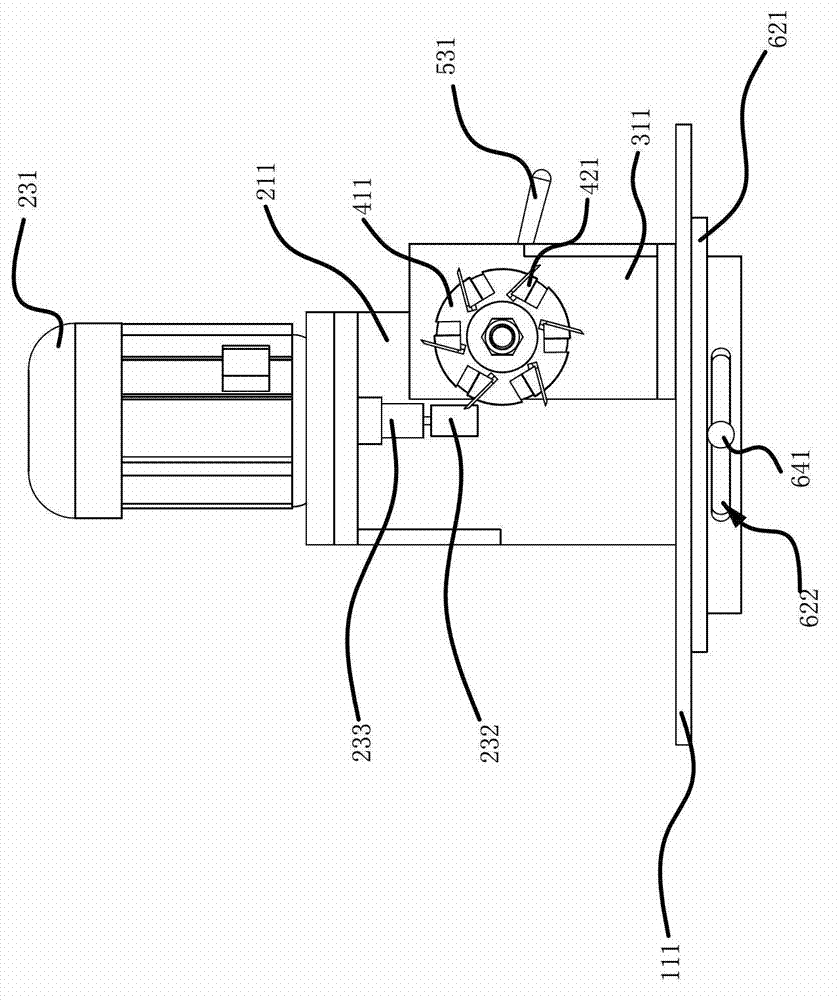

[0028] Such as Figure 1 to Figure 4 As described above, a sharpening device for grinding a shaped blade 131 includes a workbench 111, a motor 231 with a grinding wheel 232 fixed on the motor 231 shaft, and a cutter head 411 for fixing the shaped blade 131. In the first embodiment Forming blade 131 such as Figure 5 As shown, the emery wheel 232 is fixed on the motor shaft through a collet 233, the collet 233 is a common collet available on the market, a motor support 211 is fixed on the workbench 111, and the motor 231 is arranged on the motor support 211 and can be Sliding in the horizontal direction, the workbench 111 is provided with a cutterhead support 311, the cutterhead support 311 can move along the table top of the workbench 111, the cutterhead support 311 passes through a rotating shaft 321, the rotating shaft 321 and the cutterhead support 311 axially Fixed circumferential rotation setting, the cutterhead 411 is fixed on the rotating shaft 321 and is positioned at...

Embodiment 2

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the cutter head support 311 includes a seat plate 312 and a fixed plate 313 vertically fixed on the seat plate 312, and the rotating shaft 321 is vertically installed on the fixed plate 313 Above, the cutter head 411 is located on one side of the fixing plate 313, the fixing mechanism includes a nut and a bearing, the other side of the fixing plate 313 is provided with a positioning groove, the outer ring of the bearing is fixed on the groove wall of the positioning groove, the nut and the bearing The outer end surface of the inner ring of the rotating shaft 321 is fixed, and the rotating shaft 321 is located at the other end of the fixed plate 313 and is provided with a thread. The rotating shaft 321 passes through the inner ring of the bearing and the nut is connected with the thread of the rotating shaft 321. The index plate 441 is fixedly mounted on the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com