Efficient wood board deburring equipment for building construction

A technology for building construction and deburring, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems affecting the use of building construction, low efficiency, and affecting the normal progress of building construction, so as to improve the efficiency of deburring , The effect of speeding up the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

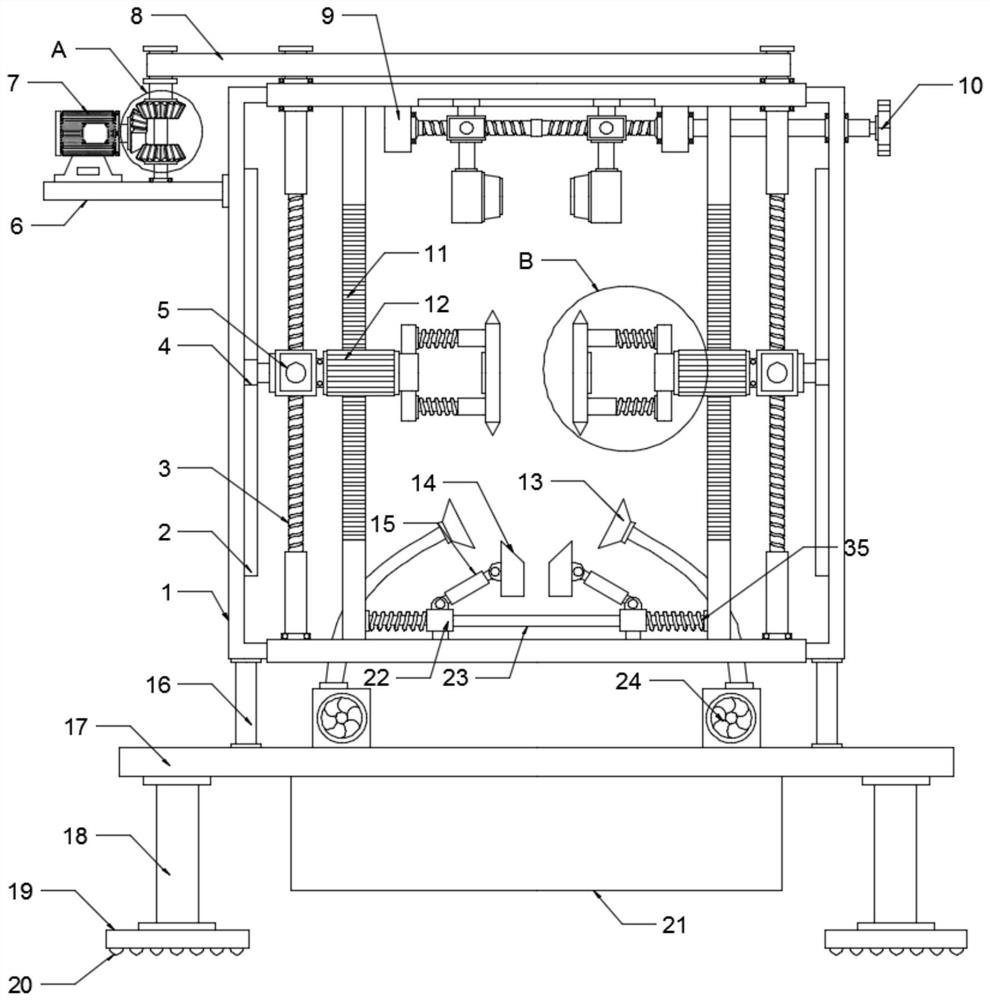

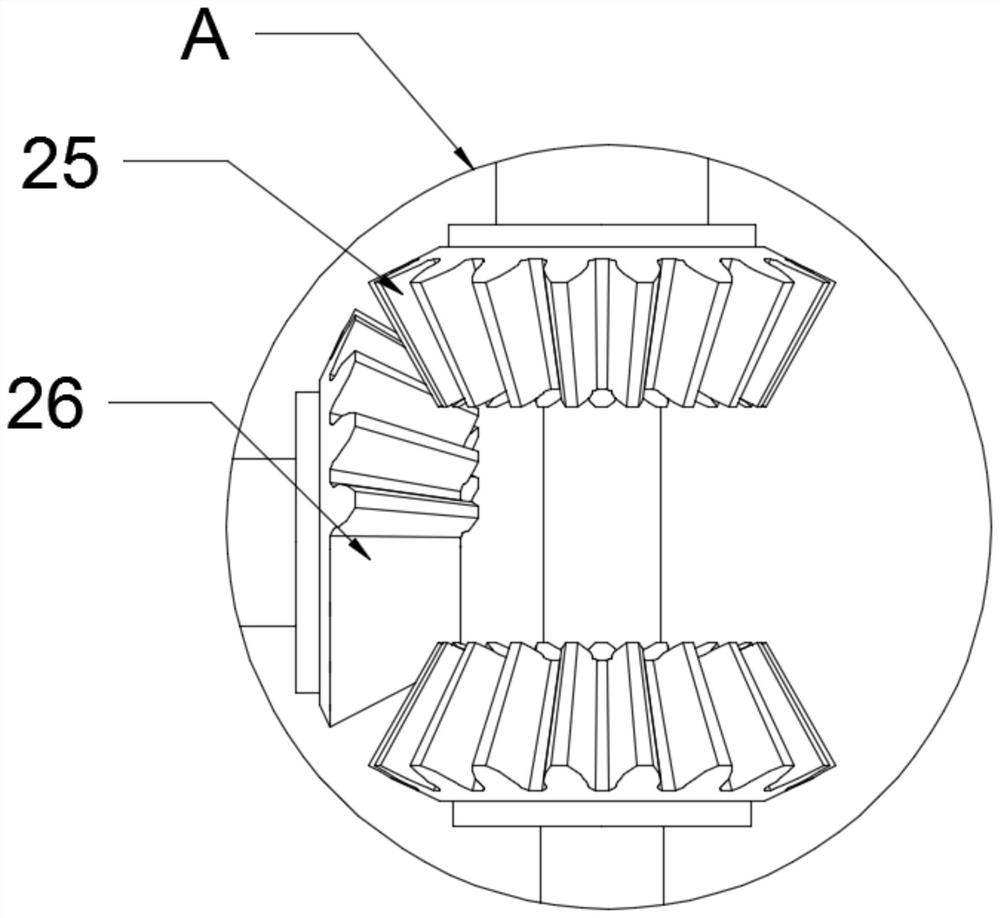

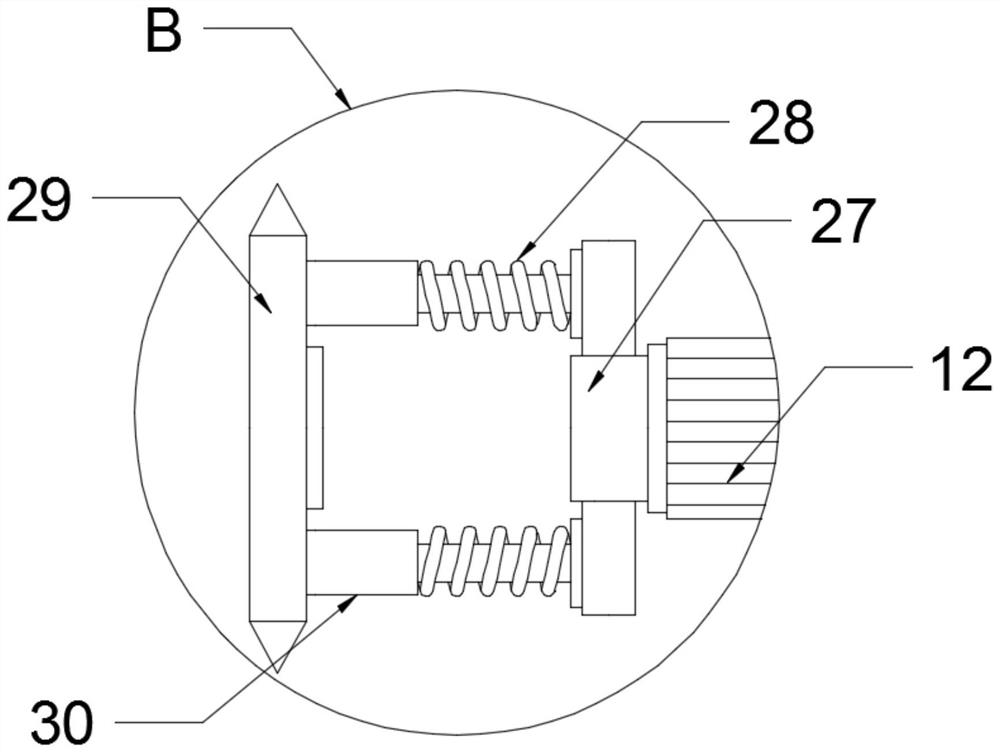

[0022] see Figure 1-5 , a kind of high-efficiency deburring equipment for wooden boards for building construction, comprising a processing box 1 and a supporting base 17, supports 9 are symmetrically arranged on the left and right sides of the upper side of the processing box 1, and screw rods 32 are arranged between the support 9, and the screw rods 32 is rotatably connected with the support 9, the right end of the screw 32 is extended and fixedly connected to the handle 10, the thread directions on the left and right sides of the screw 32 are opposite, the left and right sides of the surface of the screw 32 are symmetrically provided with nuts 31, and the nuts 31 can be With the rotation of the screw rod 32 moving left and right in the horizontal direction, the clamp 33 is fixed below the nut 31, and the wooden board to be processed is placed between the clamps 33 on the left and right sides. By turning the handle 10, the handle 10 drives the screw rod 32 to rotate, left and...

Embodiment 2

[0030] see figure 1 , on the basis of Embodiment 1, in order to uniformly collect and process the wood chips generated during grinding, a vacuum cleaner 24 is symmetrically arranged on the left and right sides of the upper surface of the support base 17, and the dust collector 24 is passed through the top of the vacuum cleaner 24. The tube is extended to connect to the suction port 13, and the lower surface of the support base 17 is provided with a collection tank 21, and the dust collector 24 is connected to the collection tank 21, and the dust collector 24 will pass through the suction port 13 to remove the waste generated during grinding. The debris is sucked into the collection tank 21 for unified collection and treatment.

[0031]The working principle of the present invention is: a kind of high-efficiency deburring equipment for wooden boards for building construction. The wooden boards to be processed are placed between the fixtures 33 on the left and right sides, and by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com