One-circle and double-grinding chamfer deburring machine and deburring method thereof

A deburring machine and deburring technology, applied in the direction of machine tools, grinders, abrasives, etc. suitable for grinding the edge of workpieces, can solve the problems of low grinding efficiency, achieve improved deburring efficiency, convenient polishing and deburring, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

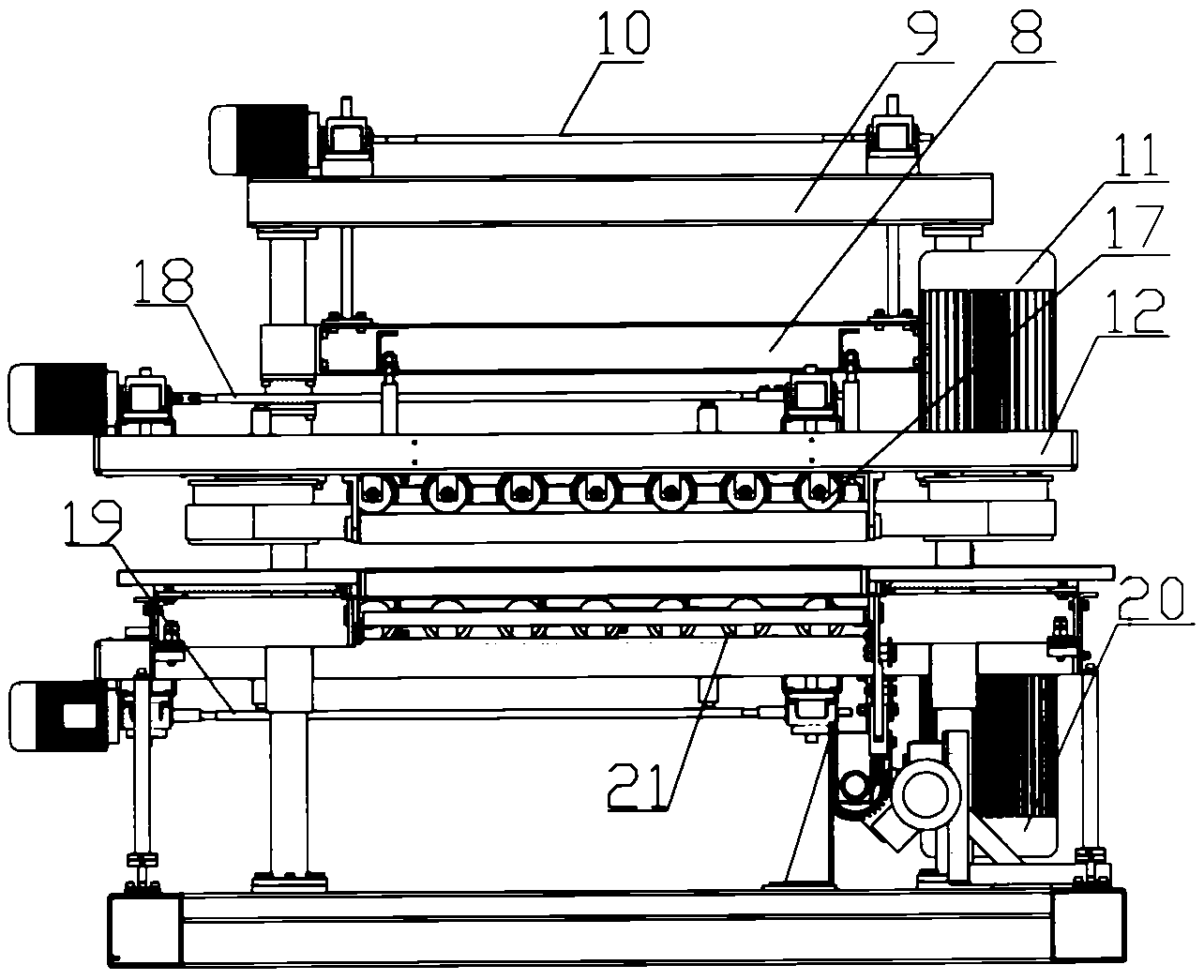

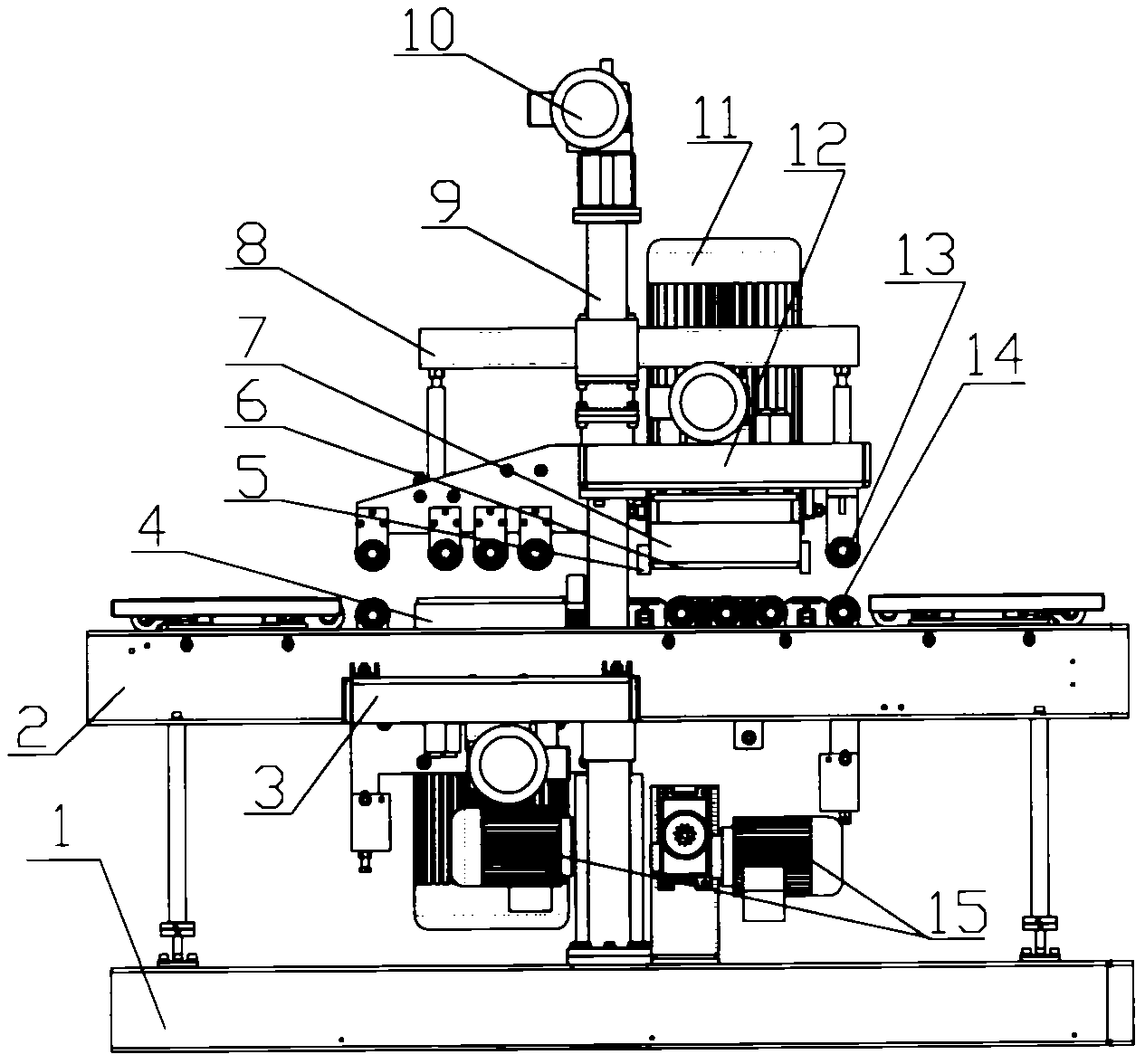

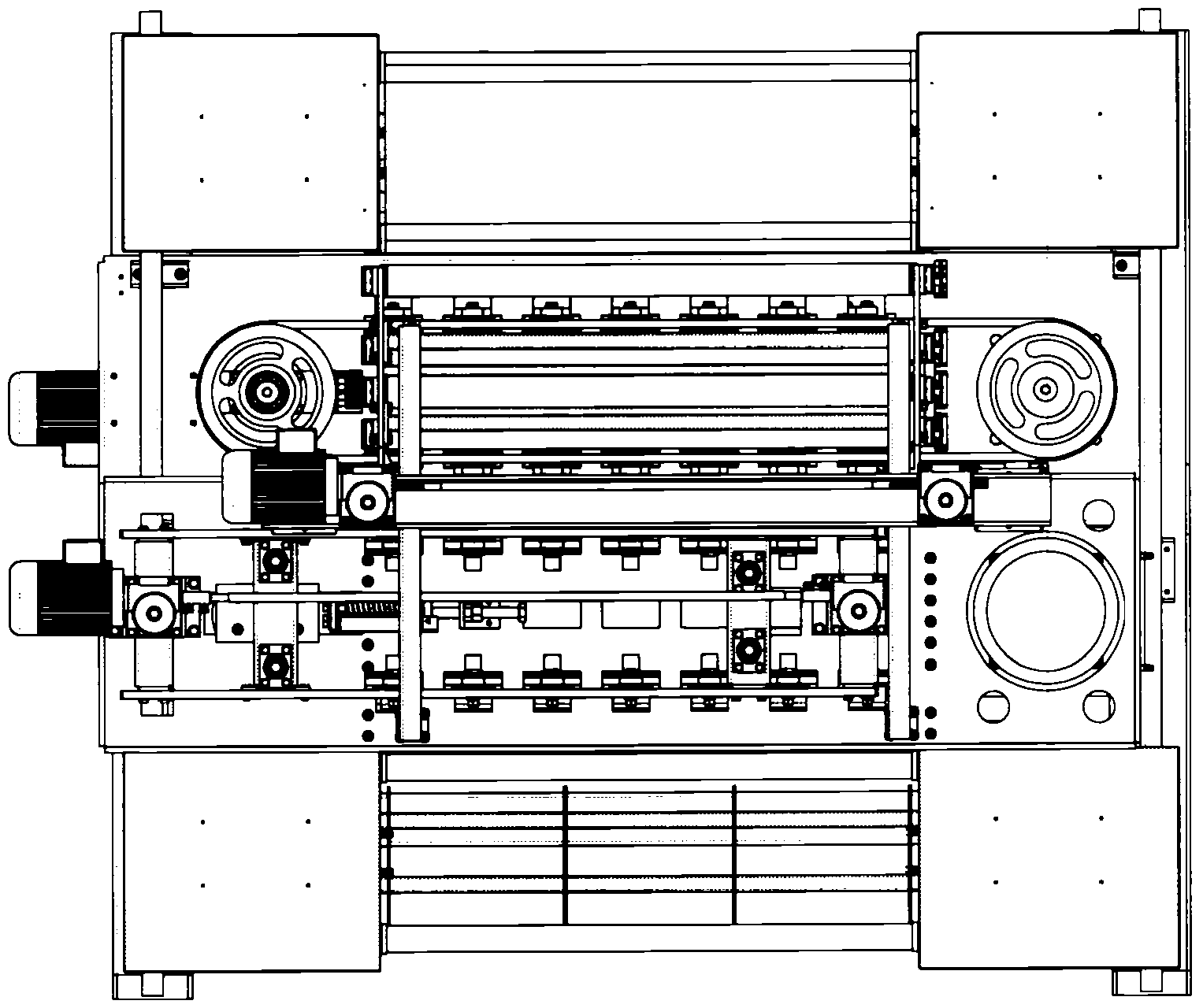

[0017] Embodiment 1: with reference to attached figure 1 . A chamfering and deburring machine with one circle and two grindings, which includes a chamfering and deburring machine, in which the frame 1 and the workbench 2 are fixedly connected by four support columns, and the grinding head gantry 9 Through the workbench 2, its lower end is fixedly connected with the frame 1, the upper brush plate 12 is set on the column of the grinding head gantry 9 and the upper brush plate 12 is driven by the motor 10 on the grinding head gantry 9 through the lifting mechanism 8 8 Drive the upper brush plate 12 to lift up and down along the column, the upper active drum 6 and the upper passive drum 6 are installed on the upper brush plate 12 and the upper active drum 6 is driven by the upper grinding head motor 11 located on the upper brush plate 12, and the upper The grinding belt 7 is horizontally sleeved on the transmission wheel formed by the upper driving drum 6 and the upper passive dr...

Embodiment 2

[0018] Embodiment 2: On the basis of Embodiment 1, a deburring method of a round two grinding chamfering and deburring machine is started. (1) The upper grinding head motor 11 drives the upper grinding head to rotate by driving the upper driving drum to drive the upper grinding head The belt 7 rotates horizontally; (2) the lower grinding head motor 20 drives the lower driving drum to rotate and drives the lower grinding belt 4 to rotate horizontally; When the passage of the upper grinding belt 7 rotates once a week, the upper abrasive block 5 fixed on the upper grinding belt 7 is under the action of the upper grinding belt pressing wheel set 17, and the upper abrasive block is in elastic contact with the surface of the workpiece. Driven by the head motor 11 and the upper driving drum, the polishing and deburring of the front of the workpiece is completed for the second time. At this time, the lower grinding belt 7 located below the workpiece rotates once under the drive of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com