Steel pipe inner burr removing device

A technology for removing burrs and steel pipes, which is applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc. It can solve the problems of difficult installation and fixation of steel pipes, low practicability, and large vibration, so as to achieve small vibration and practicality. Strong resistance, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

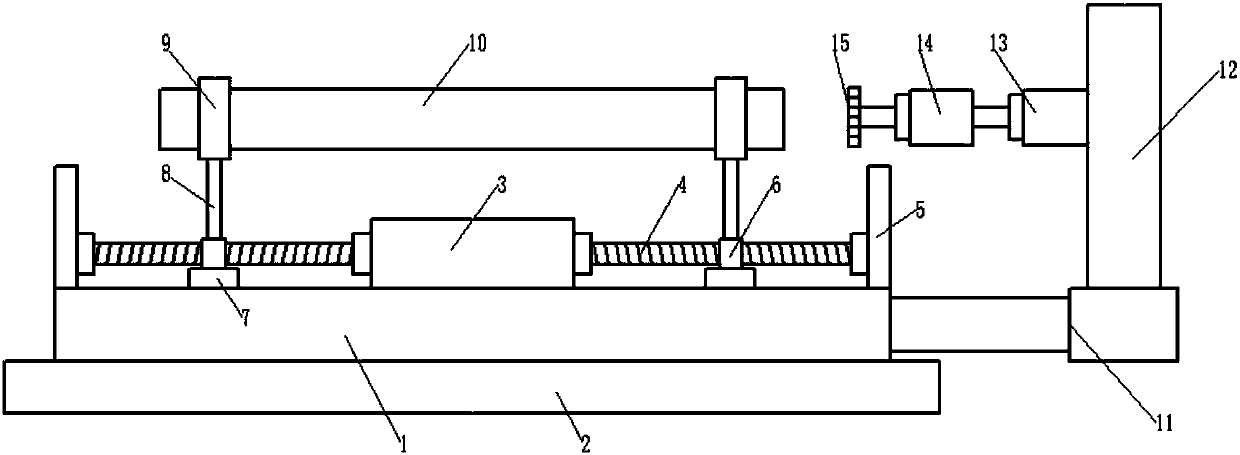

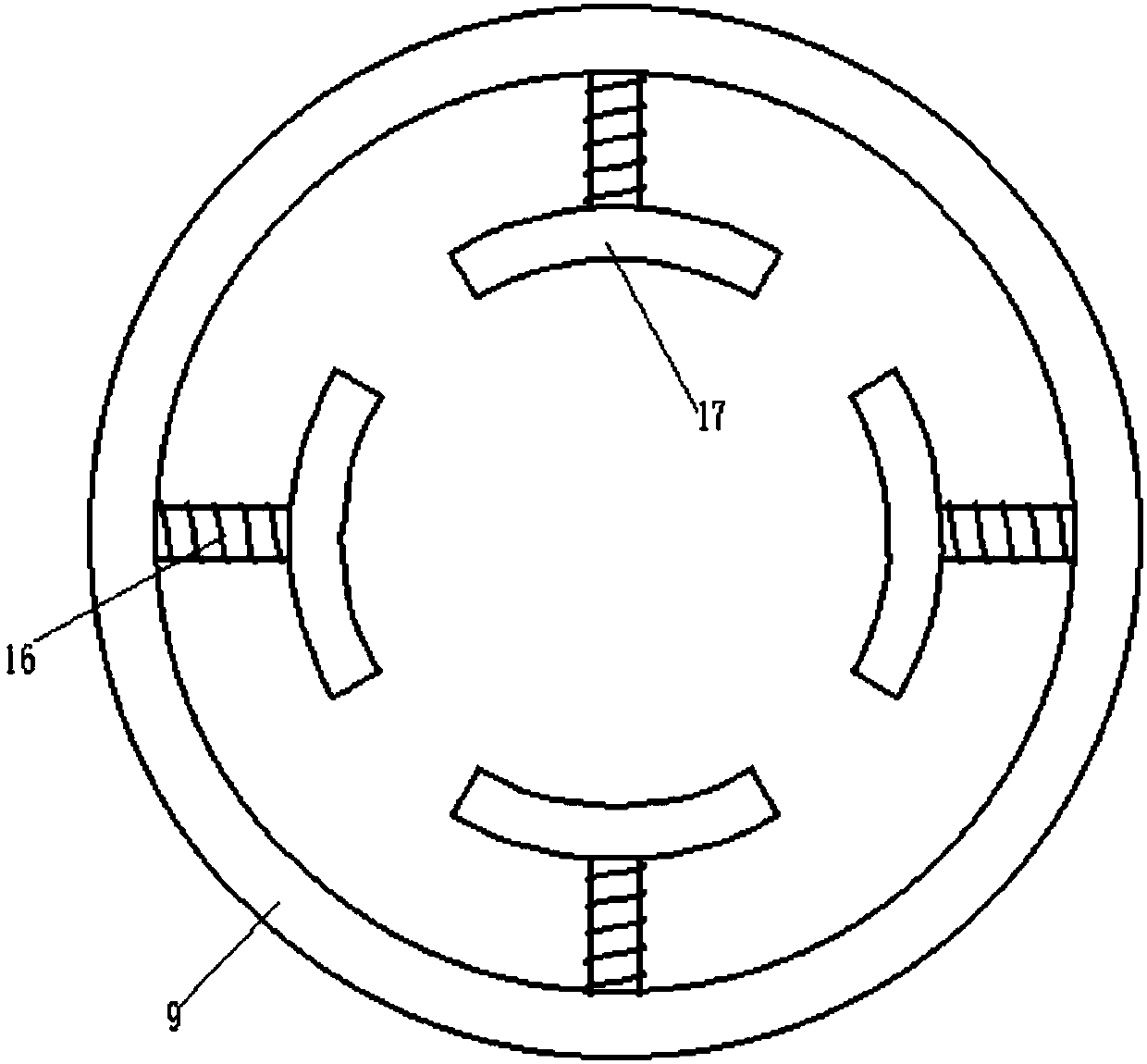

[0019] see Figure 1-2 , a device for removing burrs in a steel pipe, comprising a fixed base 1 and a grinding wheel 15; side plates 5 are fixedly connected to both sides of the surface of the fixed base 1, and a biaxial motor 3 is fixedly connected to the surface of the fixed base 1, so The two ends of the biaxial motor 3 are connected with a rotating shaft 4, and the two ends of the rotating shaft 4 are respectively connected to the side plate 5 in rotation, and the rotating shaft 4 is sleeved with a moving part 6, and the moving part The bottom of 6 is fixedly connected with a sliding block 7, the sliding block 7 is slidingly connected with the surface of the fixed base 1, the surface of the rotating shaft 4 is evenly distributed with threads, and the moving part 6 is threadedly connected with the rotating shaft 4 , the moving part 6 is fixedly connected with a connecting rod 8, the top of the connecting rod 8 is fixedly connected with a fixed part 9, the fixed part 9 is a ...

Embodiment 2

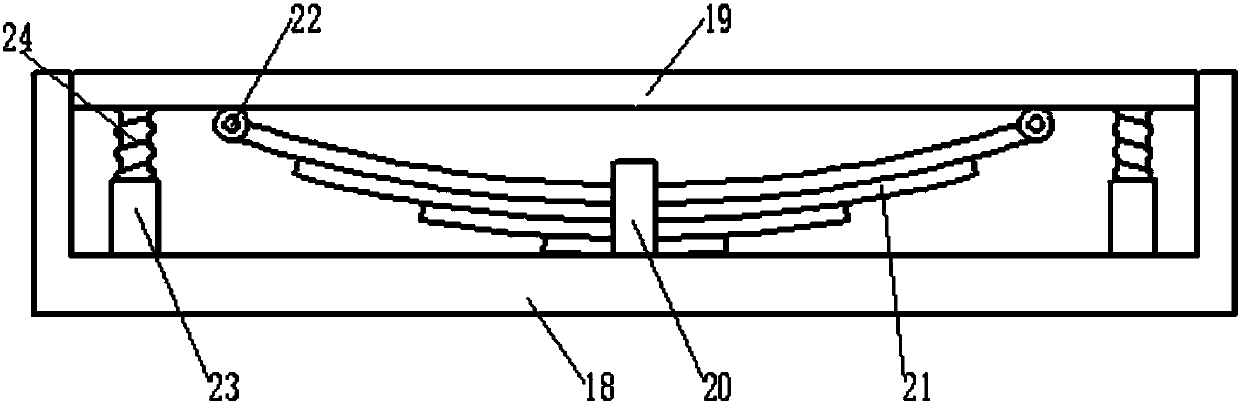

[0022] Such as figure 1 and image 3 As shown, a device for removing burrs in a steel pipe, on the basis of Embodiment 1, the bottom of the fixed base 1 is provided with a shock-absorbing base 2, and the described shock-absorbing base 2 is mainly composed of a fixed frame 18 and a sliding plate 19 The sliding rod 19 is fixedly connected to the fixed base 1, and the two ends of the sliding plate 19 are slidably connected to the fixed frame 18, and the inner bottom of the fixed frame 18 is fixedly connected with a U-shaped clamp 20. , the U-shaped clamp 20 is fixedly connected with a shock-absorbing steel plate 21, and the end of the shock-absorbing steel plate 21 is connected with a shock-absorbing roller 22, and the shock-absorbing roller 22 abuts against the lower surface of the sliding plate 19, and the inside of the fixed frame 18 is symmetrical A fixed column 23 is provided, and a sliding rod 24 is slidably connected to the fixed column 23, and a spring is sleeved on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com