Aging method of lithium ion battery cell

A lithium-ion and battery technology, applied in the aging field of lithium-ion batteries after liquid injection, can solve the problems of prolonging the battery production cycle, reducing production efficiency, and long aging time, so as to speed up full contact and shorten the manufacturing cycle , Good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above and other objects, features and advantages of the present invention more obvious, the following specifically cites the embodiments of the present invention and describes them in detail as follows.

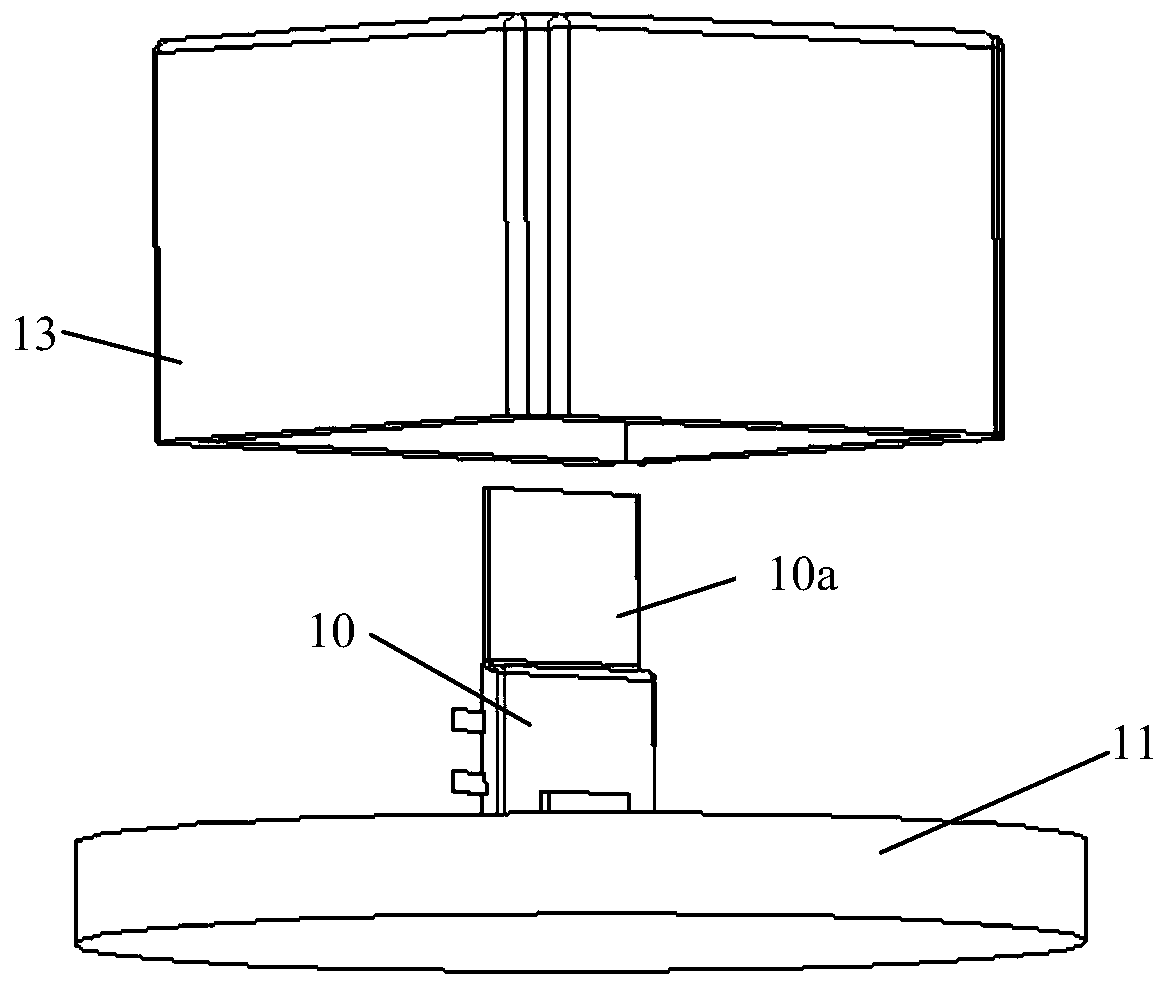

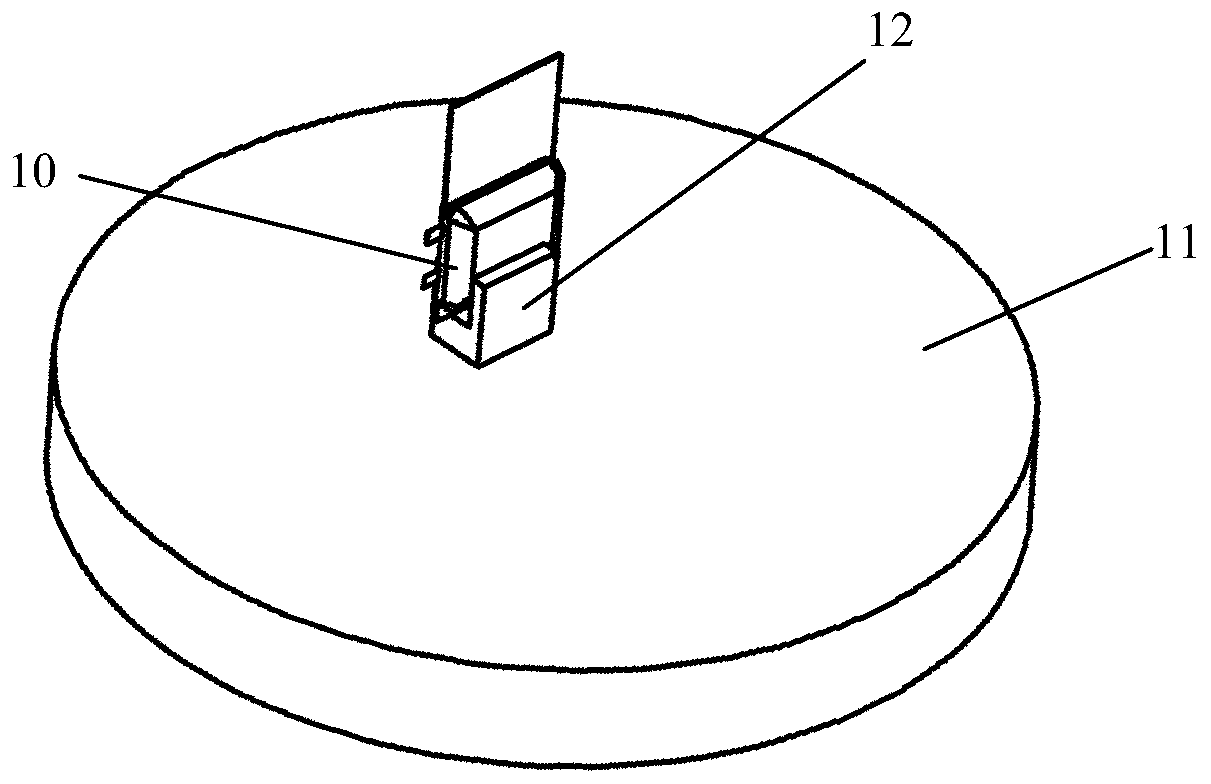

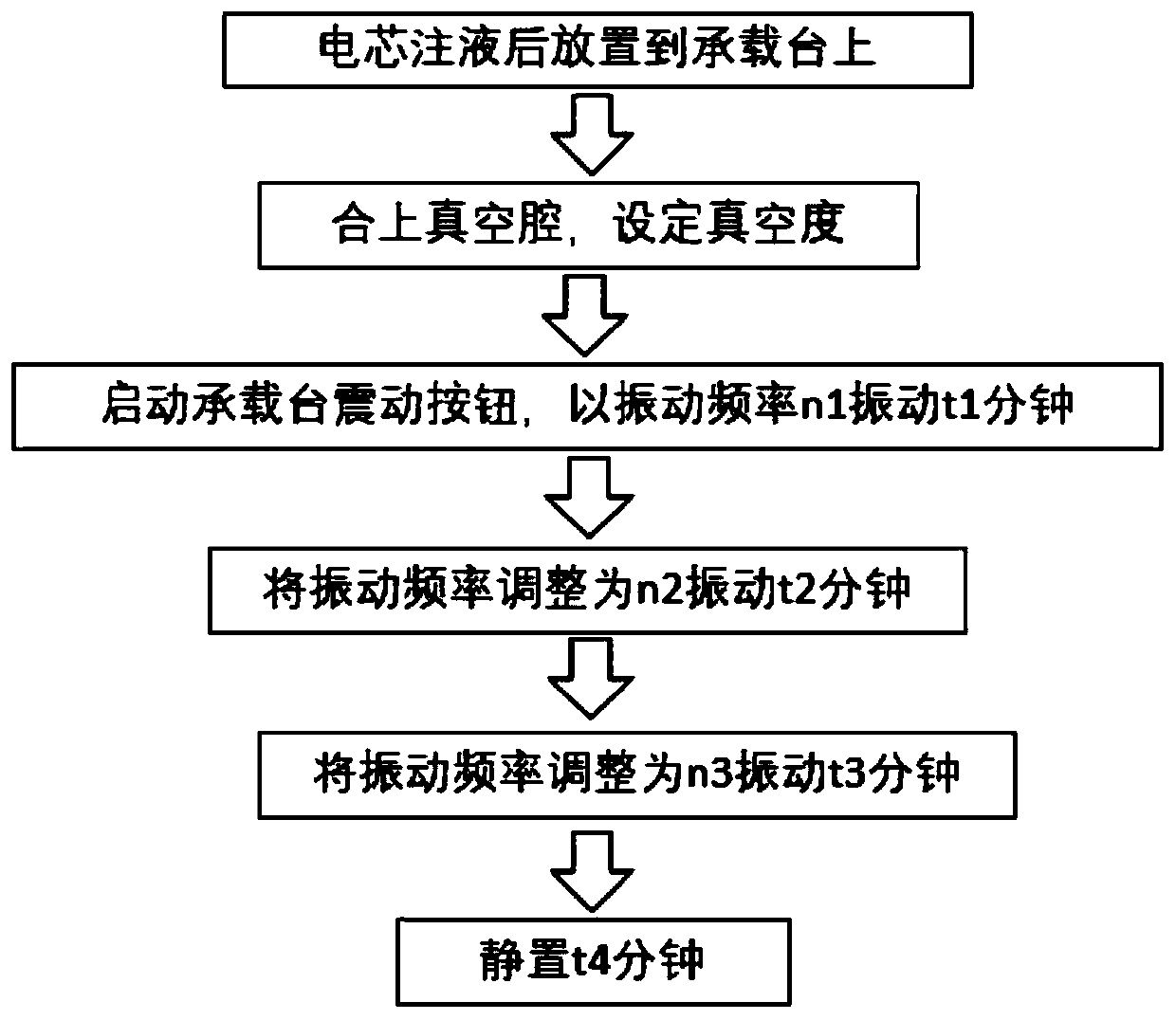

[0033] The battery cell that has been filled with liquid needs to be aged, and the aging of the battery cell is a process that makes the electrolyte in the battery cell fully infiltrate the winding core. In order to shorten the time required for cell aging, the basic idea of the method of the present invention is: on the one hand, the cell is placed on a support platform that can vibrate up and down, and the cell is in the motion of vibrating up and down during the aging process. To accelerate the infiltration speed of the electrolyte; on the other hand, at the same time, the battery is placed in a closed cavity, and the negative pressure environment formed in the closed cavity is used to reduce the resistance of the electrolyte infiltration, impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com