Touch device

A touch device, touch panel technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problem of line layer breakage, difficulty in improving yield rate, poor drop resistance, and poor compression resistance and other issues to achieve the effect of improving reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

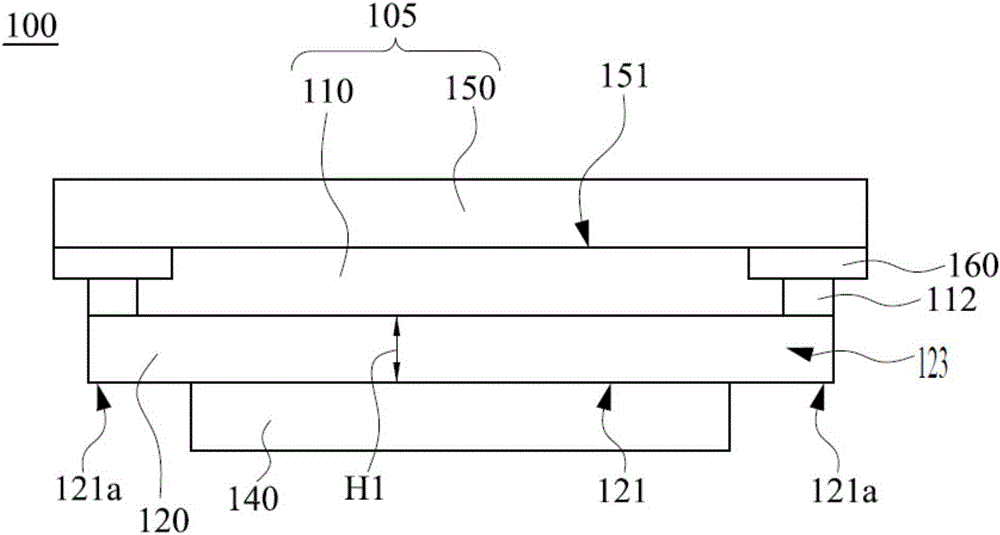

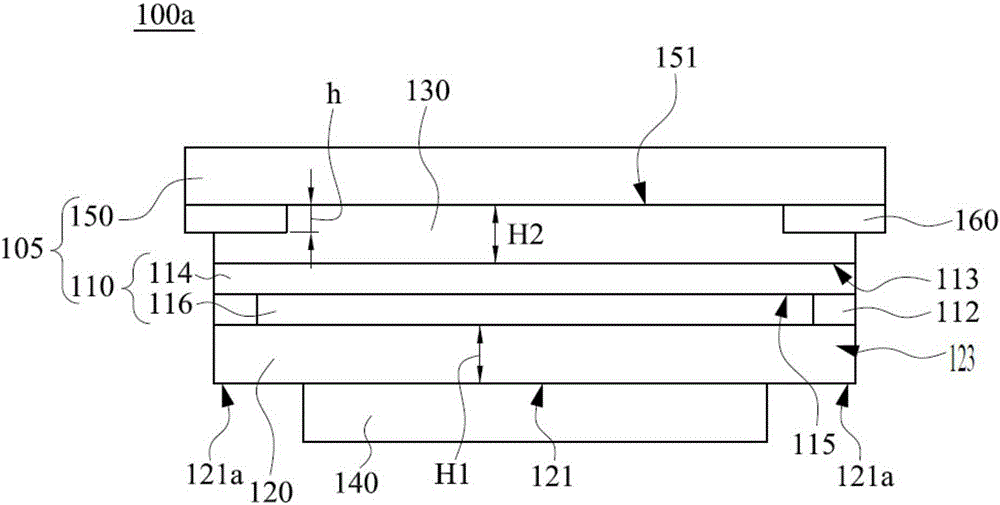

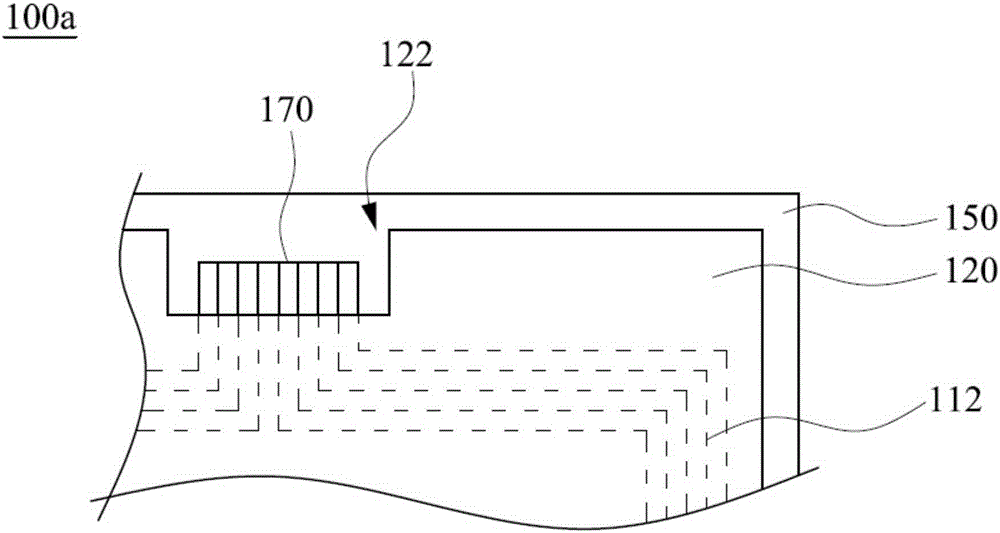

[0054] figure 1 A cross-sectional view of a touch device 100 according to an embodiment of the present invention is shown. The touch device 100 includes a touch panel 105 , a display module 140 and a first adhesive layer 120 . The touch panel 105 has a circuit layer 112 around it. The first adhesive layer 120 is bonded between the touch panel 105 and the display module 140 . The first adhesive layer 120 covers the display module 140 and has a protrusion 123 protruding from an edge of the display module 140 . In addition, the protruding portion 123 of the first adhesive layer 120 at least covers the circuit layer 112 , and the surface 121 a of the protruding portion 123 away from the circuit layer 112 has no adhesive.

[0055] With such a design, the first adhesive layer 120 can not only fit the display module 140 and the touch pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com