Device and method for recovering tert-butyl alcohol by using dividing-wall column in combination with heat pump technology

The technology of a dividing wall rectifying tower and heat pump technology is applied in the field of recovering tert-butanol in a dividing wall rectifying tower combined with heat pump technology, which can solve the problem of consuming large electric power and circulating cooling water, high energy cost of rectification process and affecting product yield. and other problems, to achieve the effect of saving equipment investment, large operating capacity, and significant energy-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

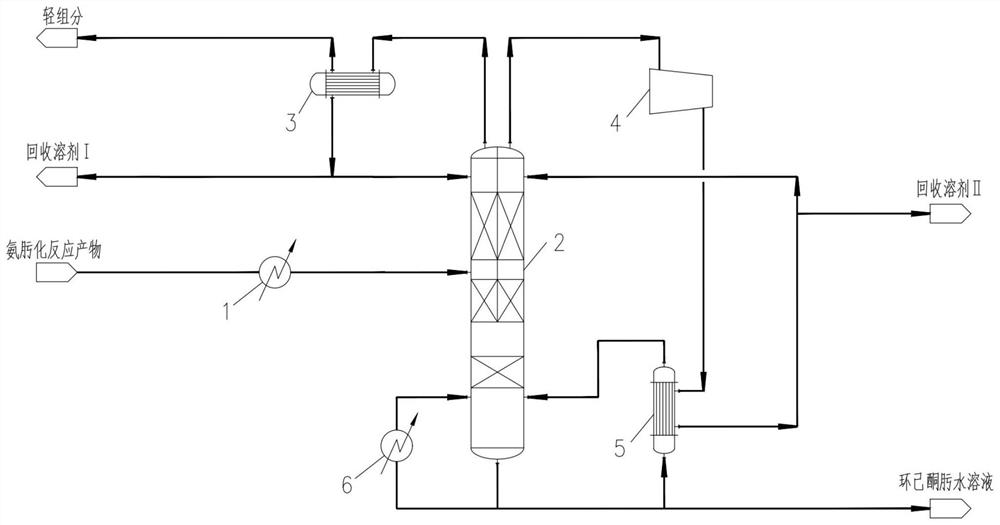

[0050] A device for recovering tert-butanol using a dividing wall rectification column combined with open heat pump technology, such as figure 1 Shown, comprise dividing wall rectifying column 2, condenser 1 3, compressor 4, dividing wall rectifying column bottom reboiler 1 5;

[0051] Wherein the tower top of the non-feed side of the dividing wall rectifying column 2 links to each other with the heat side inlet of compressor 4, the reboiler 15 at the bottom of the dividing wall rectifying column successively, and the reboiler 1 at the bottom of the dividing wall rectifying column The hot side outlet of 5 links to each other with the top of the non-feed side of the dividing wall rectifying column 2, and the bottom of the dividing wall rectifying column 2 links to each other with the cold side inlet of the reboiler 15 at the bottom of the dividing wall rectifying column. The cold side outlet of the bottom reboiler I5 of the dividing wall rectification column is connected with t...

Embodiment 2

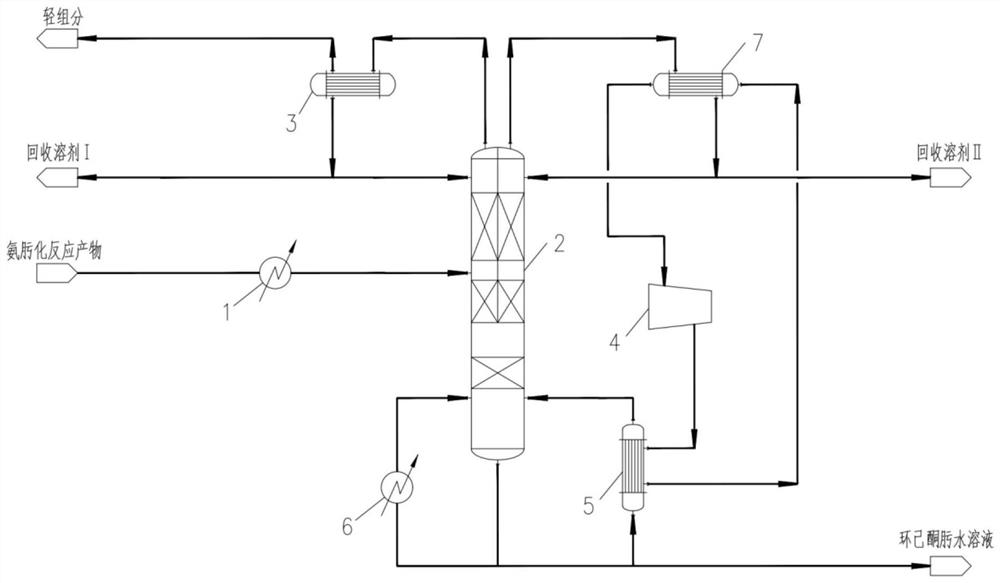

[0063] A device for recovering tert-butanol using a dividing wall rectification column combined with closed heat pump technology, such as figure 2 As shown, the device includes a dividing wall rectification column 2, a condenser I 3, a compressor 4, a reboiler I 5 at the bottom of the dividing wall rectification column, and a condenser II 7;

[0064] The top of the non-feed side of the dividing wall rectification column 2 is connected with the hot side inlet of the condenser II7, and the hot side outlet of the condenser II7 is connected with the upper part of the non-feed side of the dividing wall rectification column 2; The tower bottom of the distillation column 2 is connected with the cold side inlet of the bottom reboiler I 5 of the dividing wall rectification column, and the cold side outlet of the bottom reboiler I 5 of the dividing wall rectification column is connected with the bottom of the dividing wall rectification column 2 connected;

[0065] The top of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com