Structural wood-based gypsum composite material and preparation method thereof

A technology for composite materials and structures, applied in wood treatment, impregnated wood, wood impregnation, etc., can solve problems such as poor fire resistance, achieve high mechanical properties, easy low-cost manufacturing, and simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

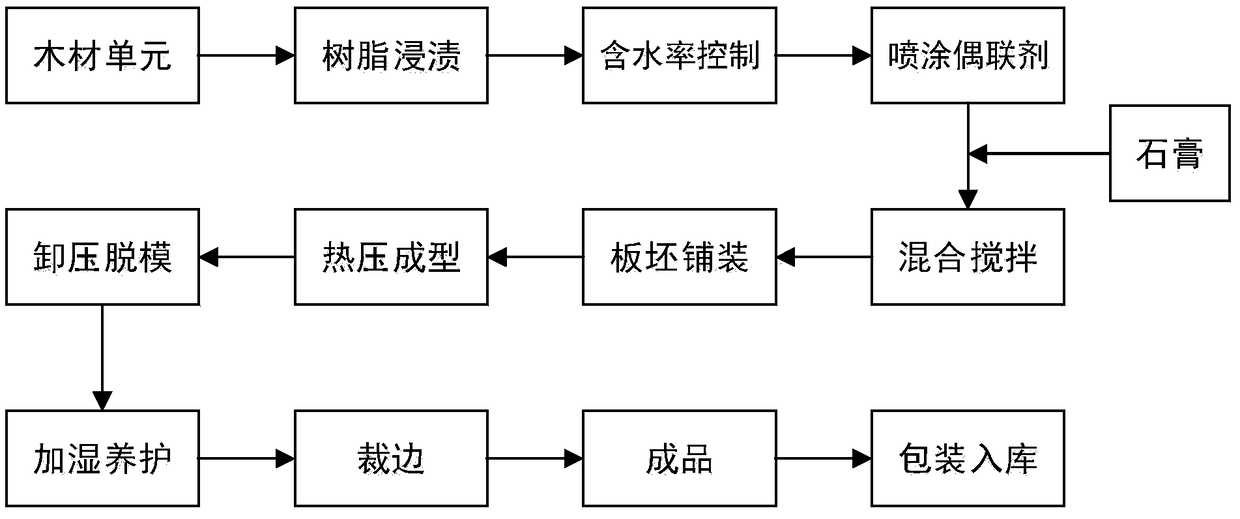

[0037] Such as figure 1 Shown is a wood-based gypsum composite material for structure and its preparation method. The wood unit, that is, wood shavings, is impregnated with phenolic resin in advance, and the impregnated wood shavings are dried to control the moisture content, and then sprayed on the surface after drying Silane coupling agent, and mixed with gypsum to pave the slab, and then use hot pressing to ensure that the cured phenolic resin will bond the gypsum and shavings to form, perform pressure relief and demoulding, and then humidify and maintain to prepare the structure Composites with wood-based gypsum.

[0038] Among them, the ratio of wood to paste is 0.35. In order to reduce equipment investment and increase turnover speed, the wood shavings are pre-impregnated with phenolic resin with a solid content of 45% under normal temperature and pressure. The impregnation time is at least 24 hours. Moisture content is 8%, spray silane coupling agent on its surface aga...

Embodiment 2

[0041] The specific method is the same as that in Example 1, except that the wood shavings are pre-impregnated with a phenolic resin with a solid content of 35%, and the impregnation pressure impregnation has a pressure of 0.4 MPa and an impregnation time of 40 min. The moisture content of wood shavings after drying is not higher than 6%. The added amount of the silane coupling agent is 4% of the dry shavings mass. The silane coupling agent solution uses absolute ethanol as a solvent, and its concentration is 6%, so as to ensure that the silane coupling agent is completely hydrolyzed and uniformly dispersed on the surface of the shavings. The hot-pressing temperature is 140°C, and the hot-pressing time is 20 minutes to ensure that the phenolic resin is fully cured and the board is preliminarily formed. Humidification and maintenance are carried out after hot pressing, and water spraying is used for humidification, and 0.30 times the moisture of gypsum is applied to the slab t...

Embodiment 3

[0044] The specific method is the same as that in Example 1, except that the wood shavings are pre-impregnated with a phenolic resin with a solid content of 30%, and the impregnation is pressure impregnated with a pressure of 0.8 MPa and an impregnation time of 30 minutes. The moisture content of wood shavings after drying is not higher than 4%. The added amount of the silane coupling agent is 6% of the dry shavings mass. The silane coupling agent solution uses absolute ethanol as a solvent, and its concentration is 5%, so as to ensure that the silane coupling agent is completely hydrolyzed and uniformly dispersed on the surface of the shavings. The hot-pressing temperature is 135°C, and the hot-pressing time is 25 minutes to ensure that the phenolic resin is fully cured and the board is initially formed. Humidification and maintenance are carried out after hot pressing, and water spraying is used for humidification, and 0.30 times the moisture of gypsum is applied to the sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com