Deep sea steel catenary vertical pipe touchdown point power response analyzing method

A steel catenary and dynamic response technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the accuracy of the analysis results is not high enough, and the influence of seabed soil suction on the steel catenary riser flow is not considered. Constraints of line segments, non-linearity of support reaction force of seabed soil, etc. are not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below in conjunction with the accompanying drawings.

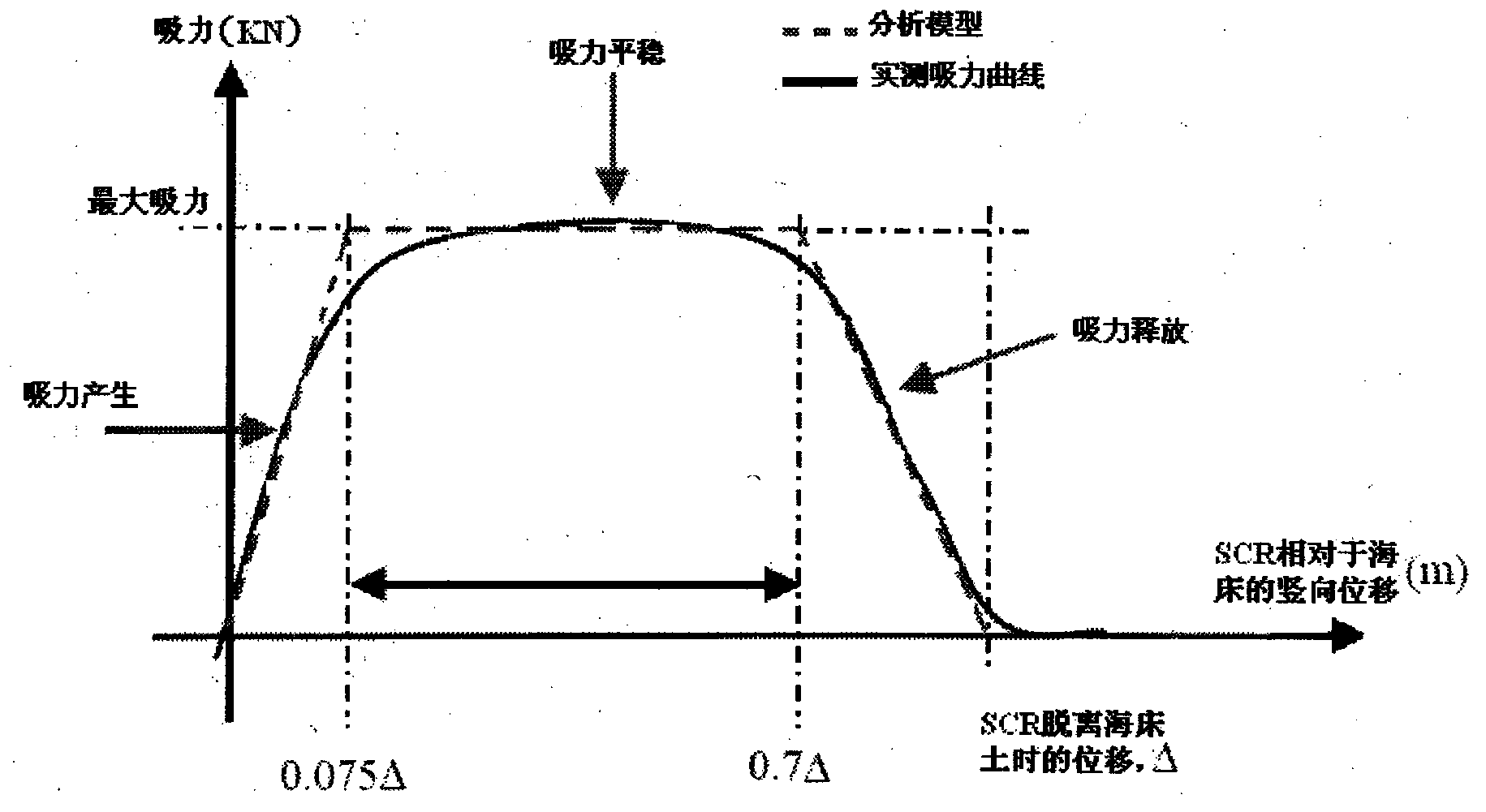

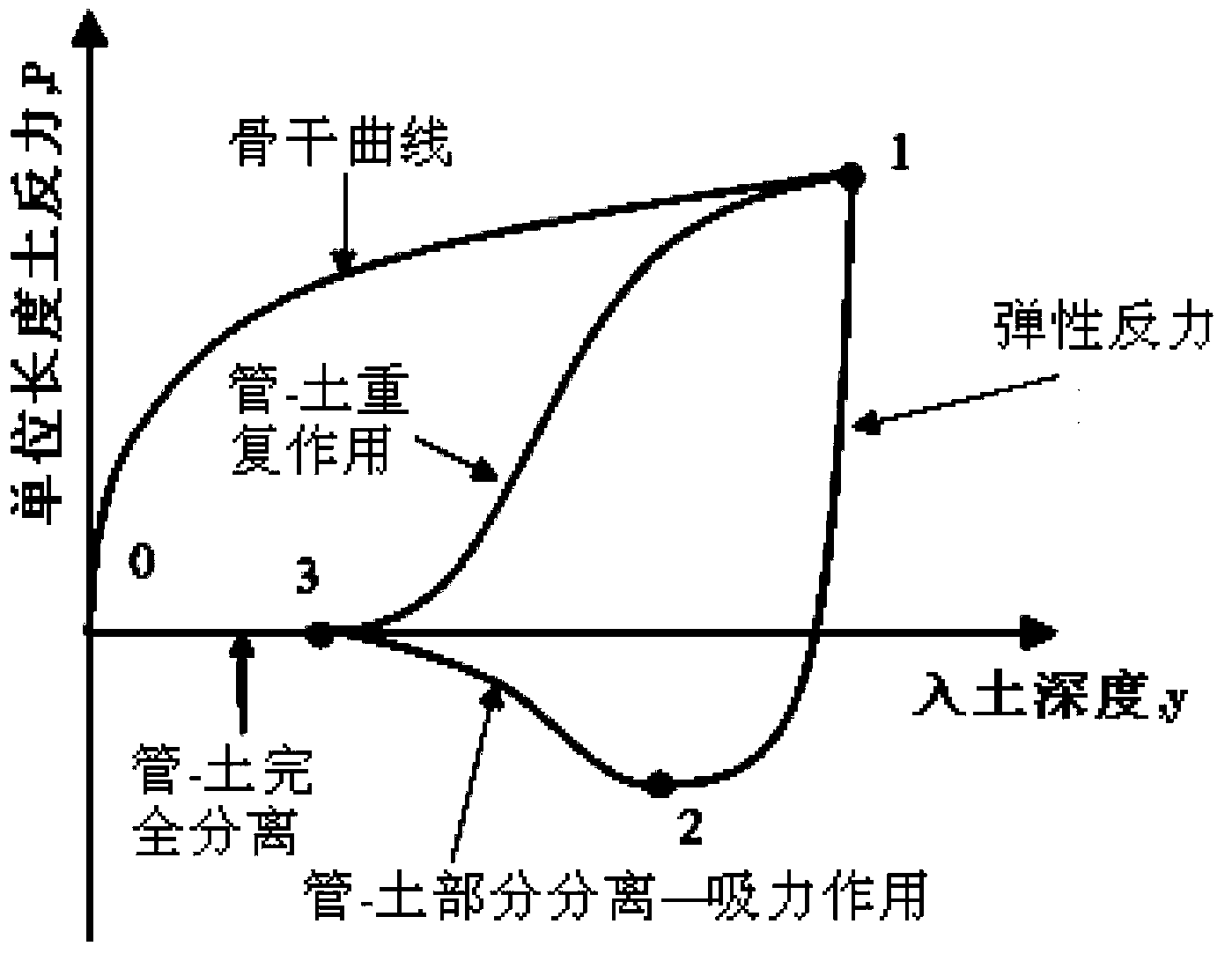

[0070] The present invention adopts the overall analysis method of the floating platform and the steel catenary riser, adopts the large deflection curved beam model to simulate the steel catenary riser, adopts the rigid arm unit to simulate the floating platform, and adopts the elastic foundation beam model to simulate the seabed The confinement effect of the soil and the influence of seabed soil suction are considered.

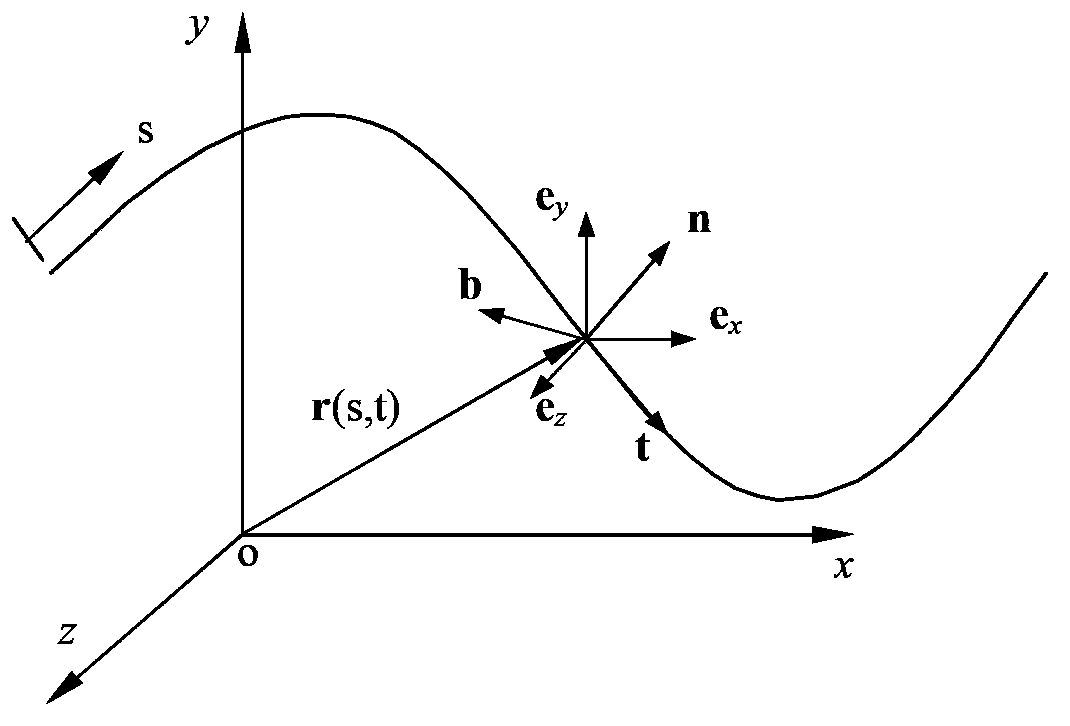

[0071] 1. Curved beam model

[0072] The coordinate system of the curved beam model that the present invention adopts is as figure 1 As shown, the equation of motion of the steel catenary riser can be deduced from this coordinate system: ρ r · · + ( B r ′ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com