Cyclone-type sucking-exhausting mechanism

A mechanical device and a swirl-type technology, which is applied in the field of swirl-type suction and exhaust mechanical devices, can solve problems such as potential safety hazards, corrosion of fans, and increased costs, and achieve the effects of stable performance, simple manufacture, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

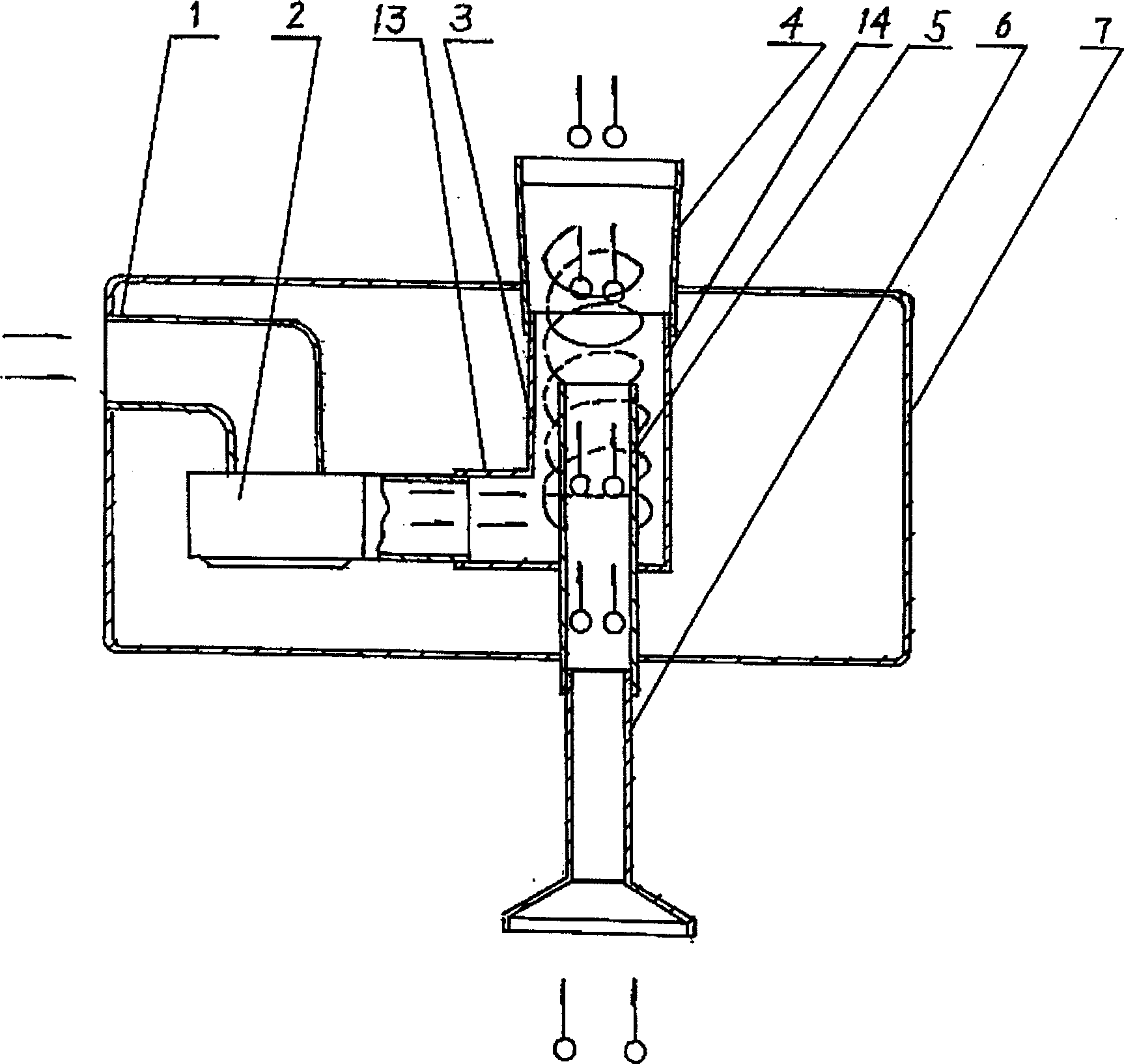

Embodiment 1

[0030] An air outlet at one end of the air collecting tube (1) is fixedly connected with an air inlet at one end of the fan (2), and the air collecting tube (1) is cylindrical. The air outlet at the other end of the blower fan (2) is fixedly connected with the air inlet tube (13) of the cyclone (3). The fan (2) blows the clean air into the cyclone (3) through the air collector (1), so that the clean air rotates in the cyclone (3), forming a rotating air flow, which is uniform along the inner wall of the cyclone (3). The flow direction rotates and rotates around the axis of the cylindrical body to the outlet end, and the rotating air flow forms a low-pressure core at the outlet end of the air inlet cylinder (5), generating suction force. The air outlet (14) of the swirler (3) is fixedly connected with the air inlet of the exhaust air duct (4), and the exhaust air duct (4) is a tubular gradual expansion shape, and the exhaust air duct (4) The end of the exhaust outlet is placed...

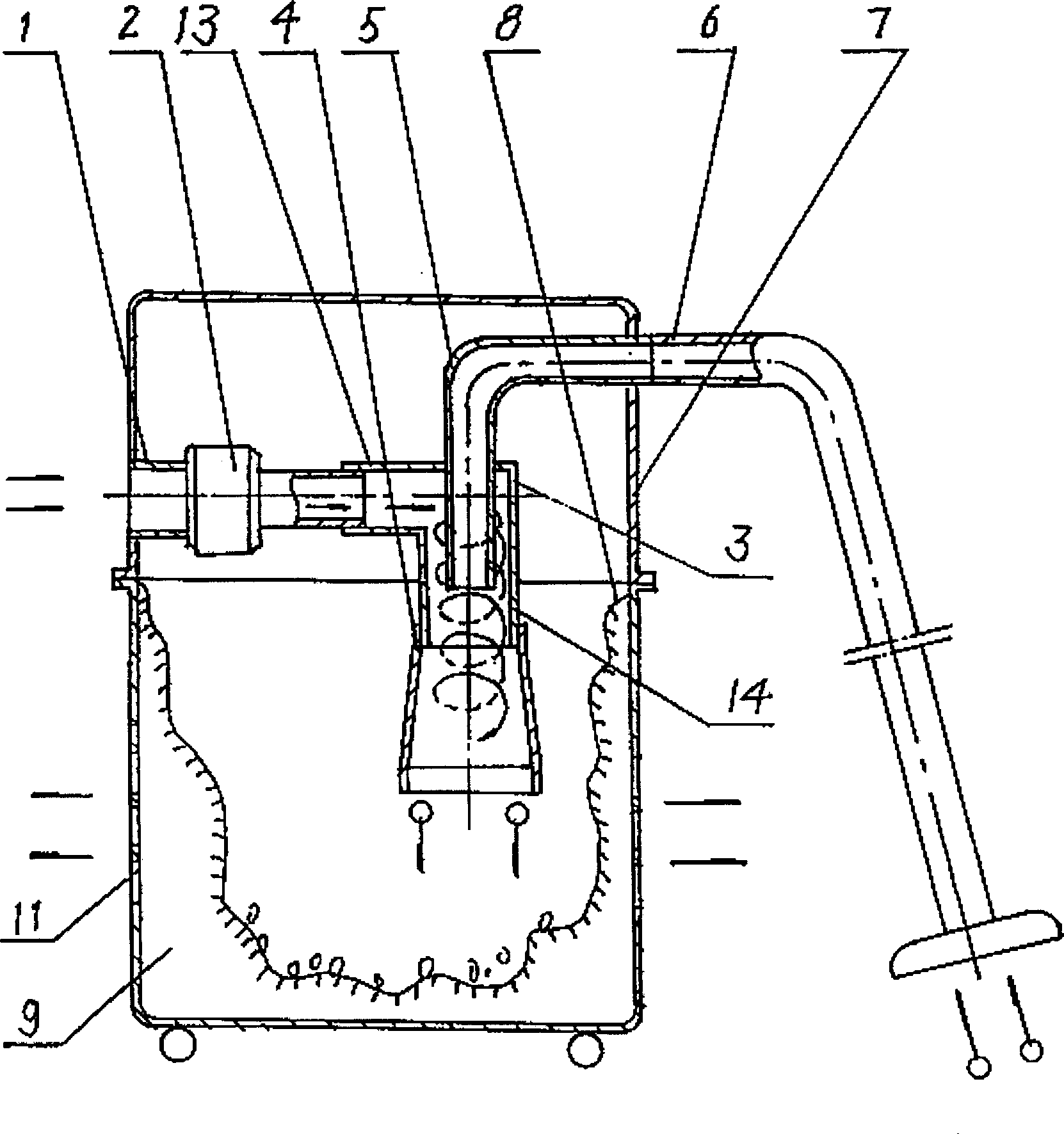

Embodiment 2

[0033]One end of the air collecting tube (1) is fixedly connected with the air inlet at one end of the fan (2), and the air collecting tube (1) is cylindrical. The air outlet at the other end of the blower fan (2) is fixedly connected with the air inlet tube (13) of the cyclone (3). The fan (2) blows the clean air into the cyclone (3) through the air collector (1), so that the clean air rotates in the cyclone (3), forming a rotating air flow, which is uniform along the inner wall of the cyclone (3). The flow direction rotates and rotates around the axis of the cylindrical body to the outlet end, and the rotating air flow forms a low-pressure core at the outlet end of the air inlet cylinder (5), generating suction force. The air outlet tube (14) of the swirler (3) is fixedly connected with the air inlet of the exhaust air tube (4), and the exhaust air tube (4) is a cylindrical gradually expanding shape. A dust collection chamber (9) is arranged at the exhaust outlet end of the...

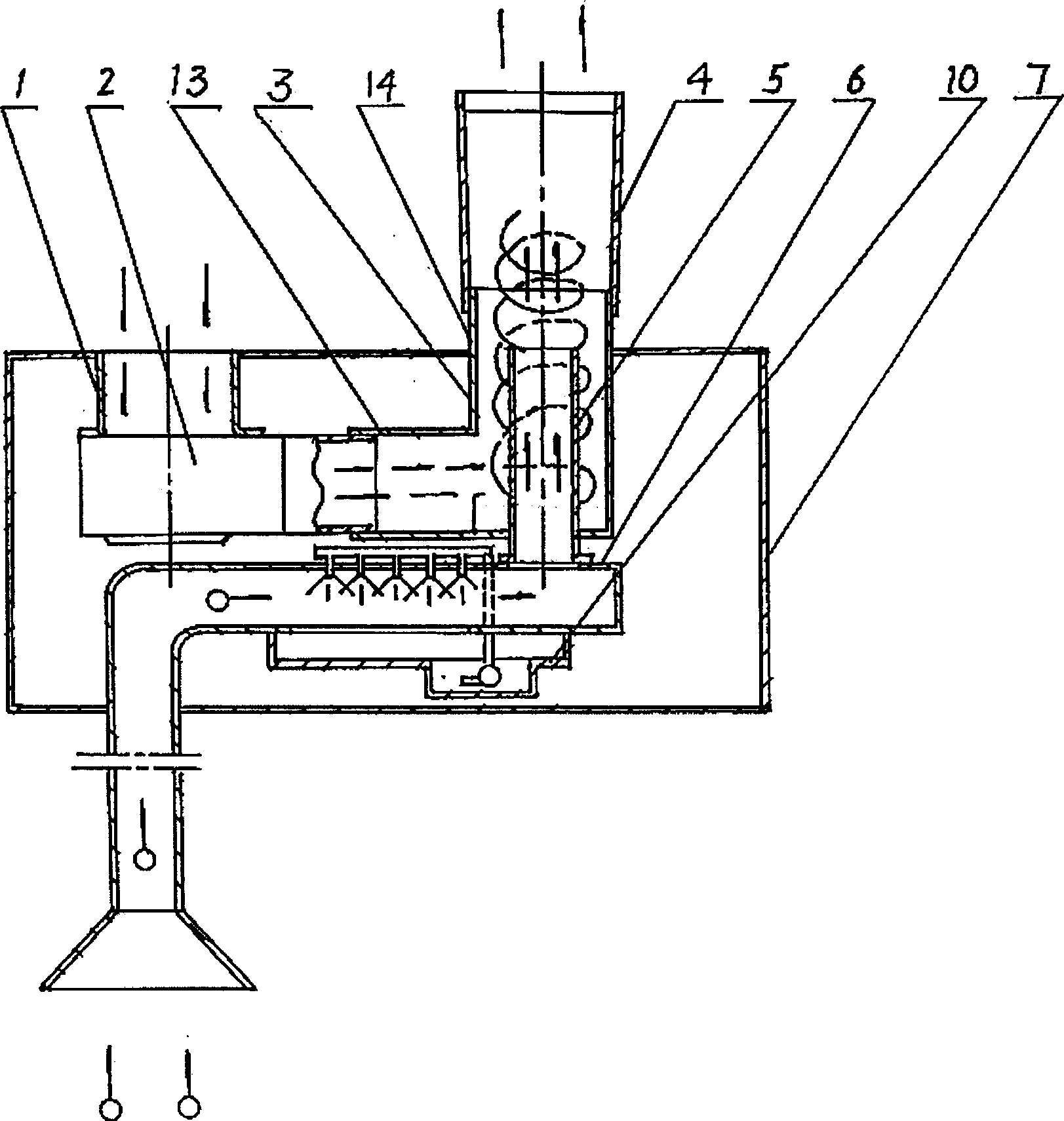

Embodiment 3

[0036] One end of the air collecting tube (1) is fixedly connected with the air inlet at one end of the fan (2), and the air collecting tube (1) is cylindrical. The air outlet at the other end of the blower fan (2) is fixedly connected with the air inlet tube (13) of the cyclone (3). The fan (2) blows the clean air into the cyclone (3) through the air collector (1), so that the clean air rotates in the cyclone (3), forming a rotating air flow, which is uniform along the inner wall of the cyclone (3). The flow direction rotates and rotates around the axis of the cylindrical body to the outlet end, and the rotating air flow forms a low-pressure core at the outlet end of the air inlet cylinder (5), generating suction force. The air outlet (14) of the swirler (3) is fixedly connected with the air inlet of the exhaust air duct (4), and the exhaust air duct (4) is a tubular gradual expansion shape, and the exhaust air duct (4) The end of the exhaust outlet is placed outside the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com