Handheld cleaning appliance

a cleaning appliance and handheld technology, applied in the field of cleaning appliances, can solve the problems of a small amount of dirt and dust passing through the separating apparatus and being carried to the airflow generator, affecting the operation of the cleaning machine, and affecting the cleaning effect, so as to achieve the effect of enduring greater wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

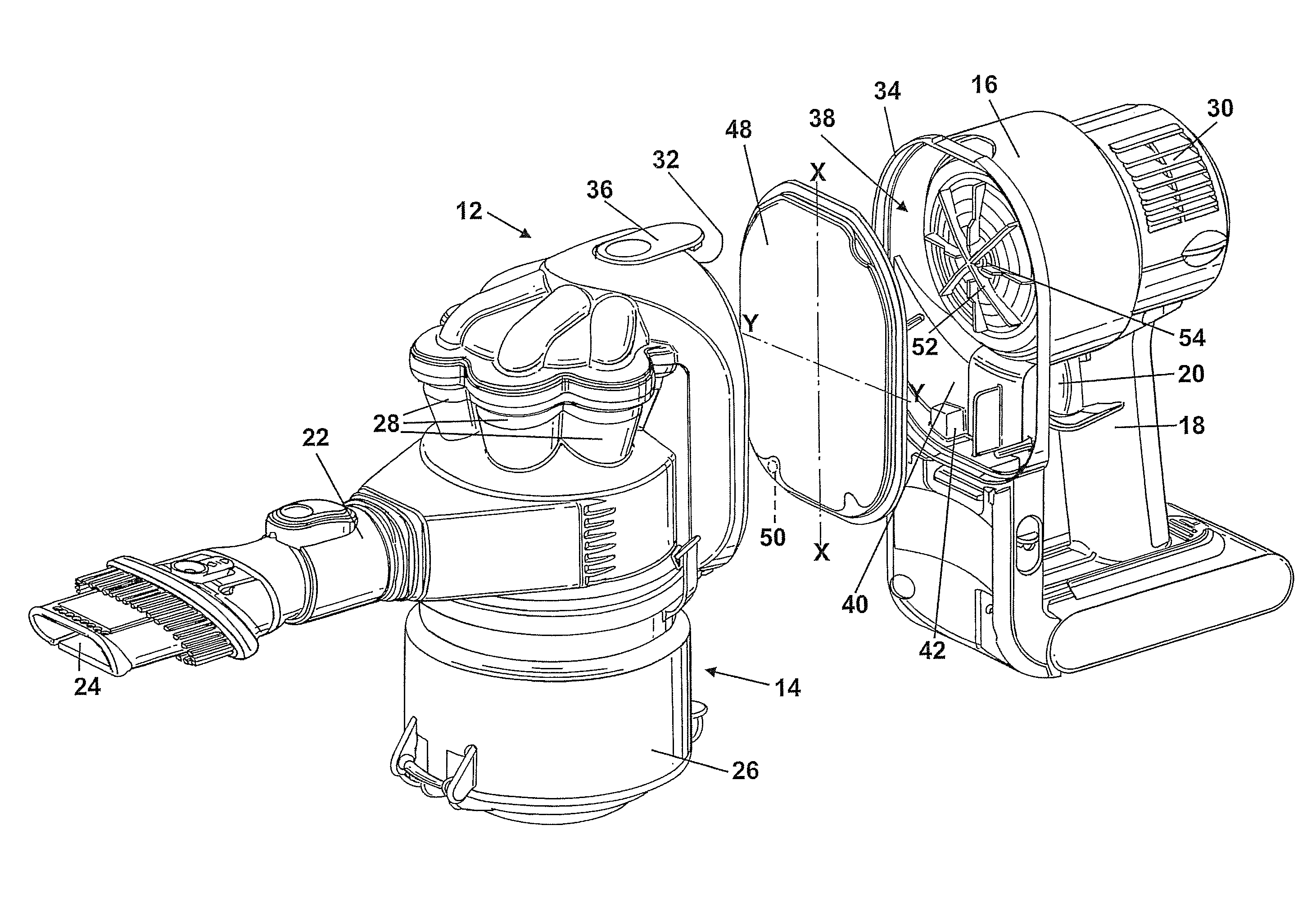

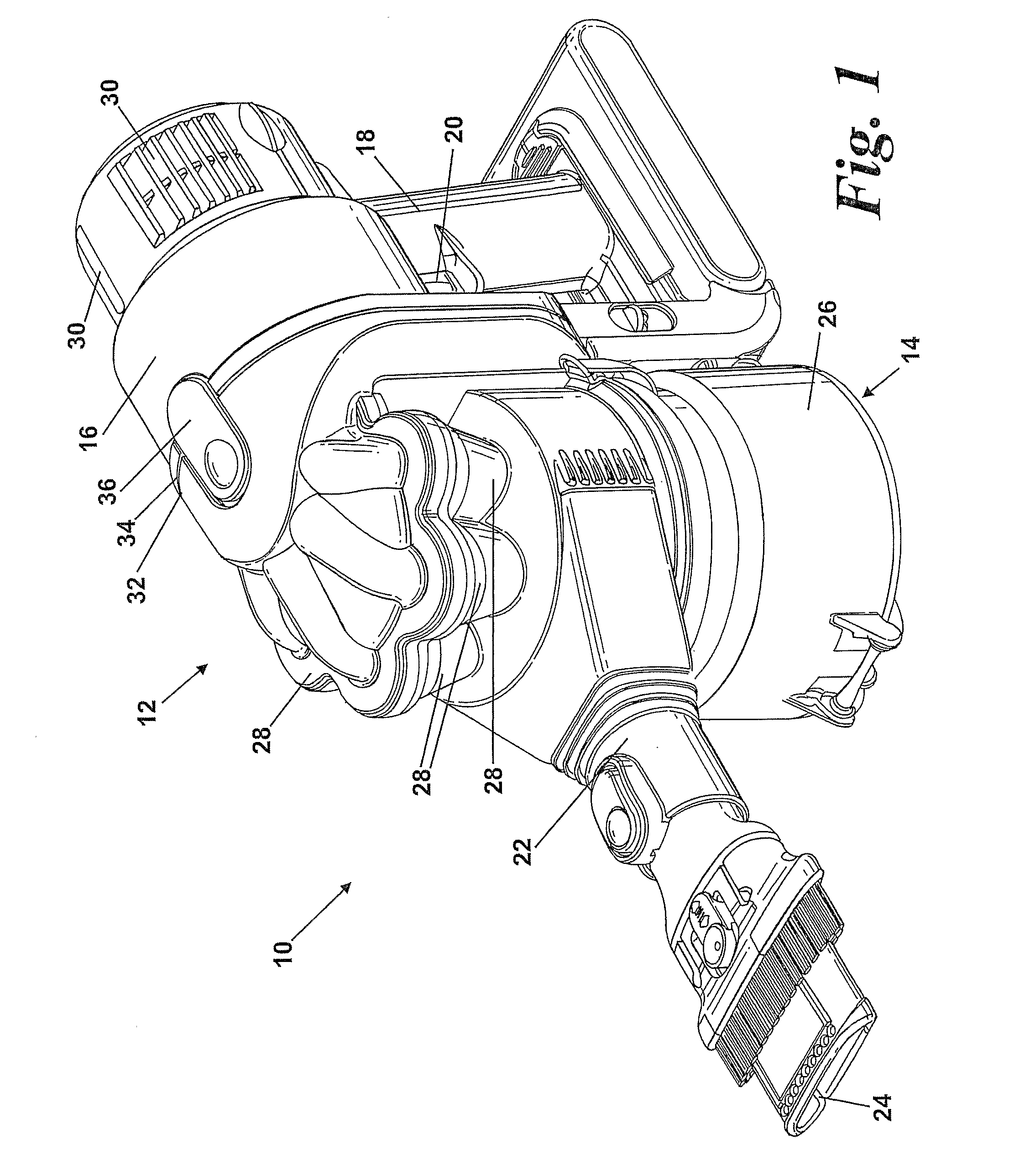

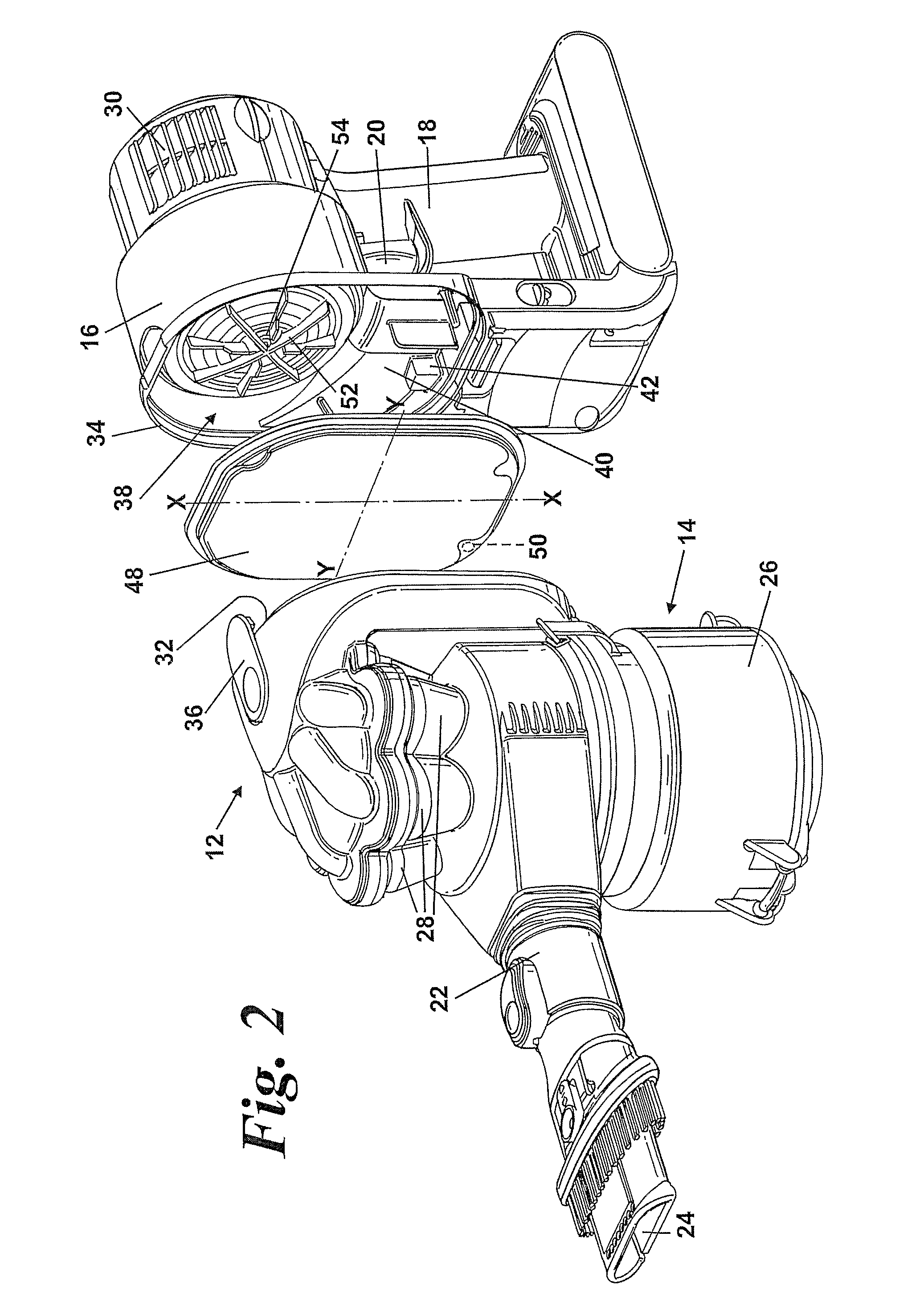

[0020]FIG. 1 shows a hand-held vacuum cleaner 10. The hand-held vacuum cleaner 10 comprises a main body 12. The main body 12 includes cyclonic separating apparatus 14 which is capable of separating dirt and dust from an airflow, a motor housing 16 and a handgrip 18 for manipulating the hand-held vacuum cleaner 10 in use. The handgrip 18 includes a trigger 20 which is positioned such that it can be manipulated by a user's finger.

[0021]The main body 12 further includes a suction conduit 22 which has a suction opening 24 at one end. The suction conduit 22 communicates with the cyclonic separating apparatus 14. The cyclonic separating apparatus 14 comprises an upstream cyclone 26 and a plurality of downstream cyclones 28. A flowpath extends from the suction opening 24, through the suction conduit 22, the cyclonic separating apparatus 14 and the motor housing 16 to a plurality of exhaust vents 30 formed in the motor housing 16.

[0022]In FIG. 1, the cyclonic separating apparatus 14 is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| mechanical failure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com